Products

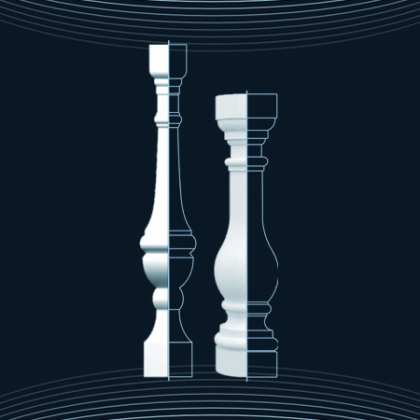

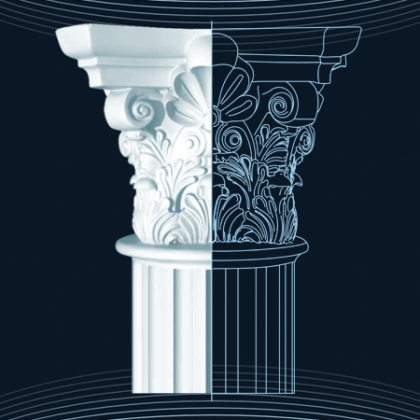

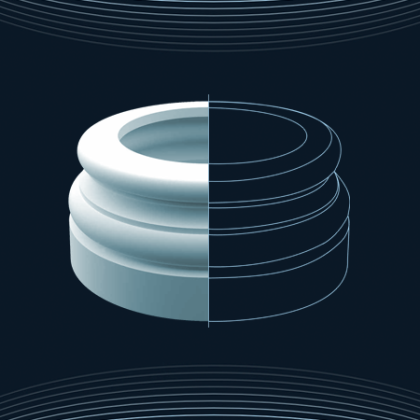

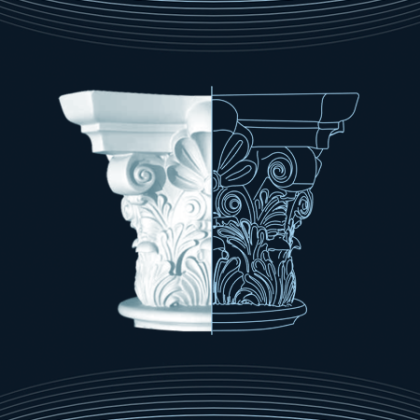

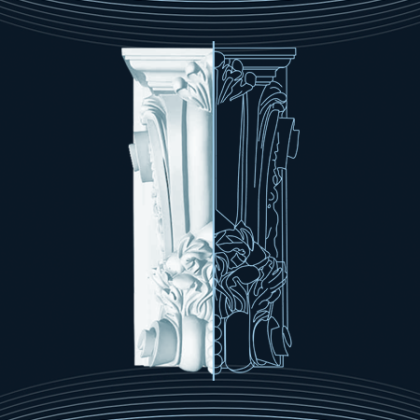

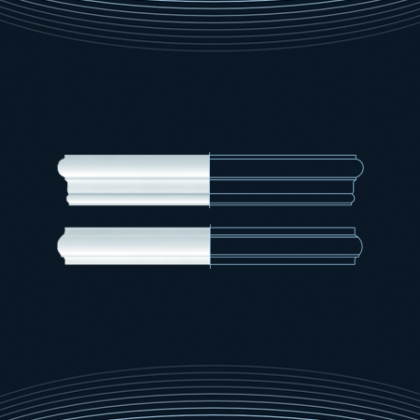

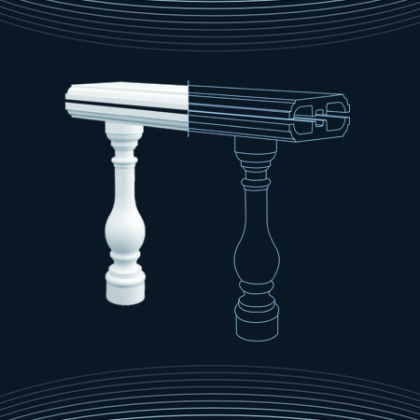

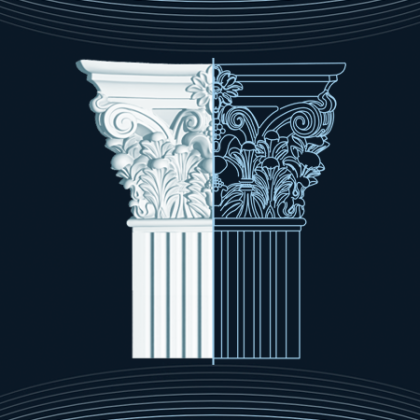

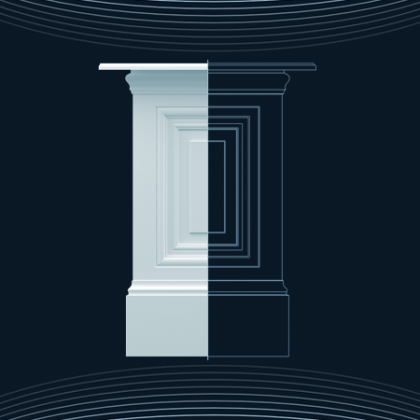

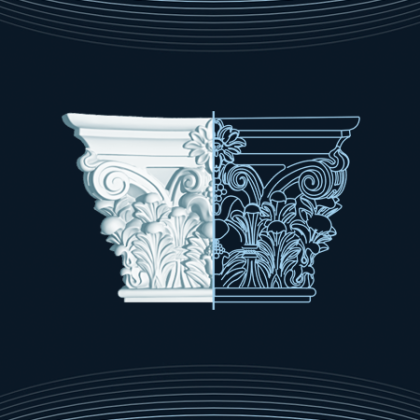

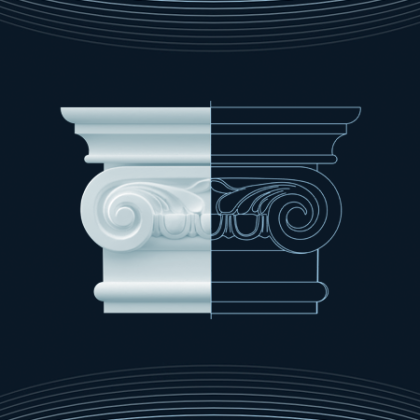

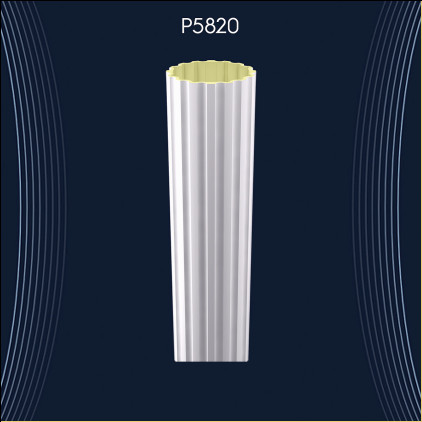

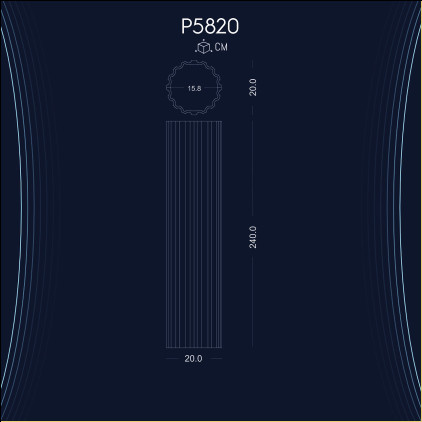

Polyurethane Fluted Columns P5820: Ionic, Doric, Corinthian Styles - Antique Elegance Decoration Designs and Ideas

1,111 lei 999.90 lei

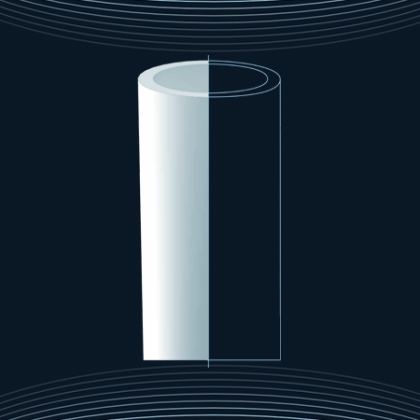

Polyurethane Fluted Column P5830: Decorative Polyurethane Columns - Broad Applications and Customization in Decor Designs and Ideas

1,520.19 lei 1,368.17 lei

Polyurethane Fluted Columns P5830_0_50: Elegance and Versatility in Architecture Decoration Models Design and Ideas

764.50 lei 688.05 lei

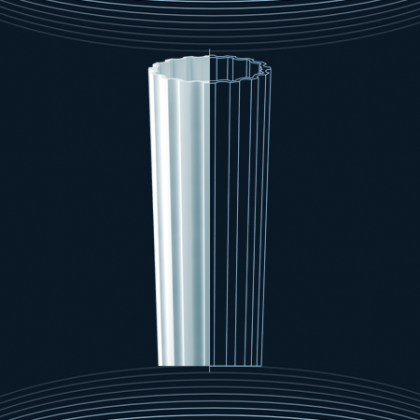

Elegant and Stylish Interior Design with P5840 Polyurethane Fluted Columns: Decorative Polyurethane Column Designs, Ideas, and Inspirations for Home Decor

2,117.50 lei 1,905.75 lei

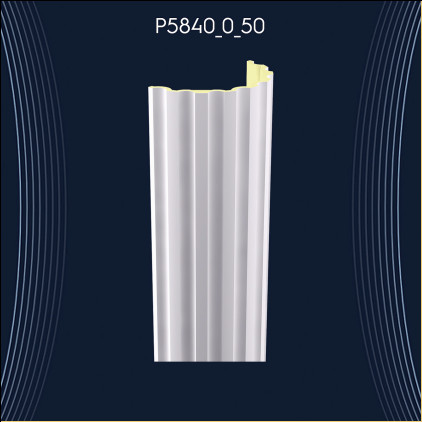

Polyurethane Fluted Column P5840_0_50 Polyurethane Columns - Economical and Competitive Decoration Models Design and Ideas

1,061.49 lei 955.34 lei

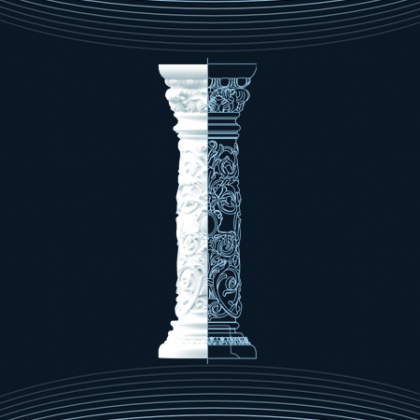

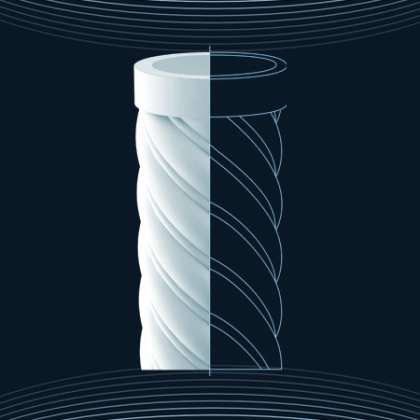

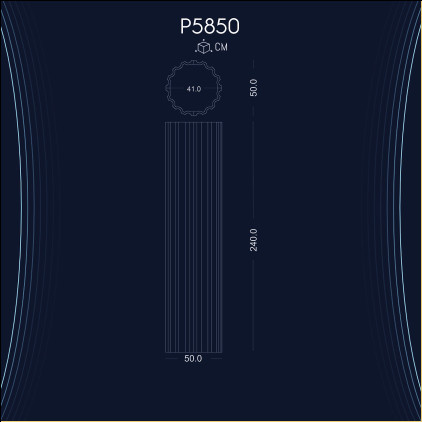

Ottoman-Inspired Unique Design Polyurethane Grooved Column P5850: Grooved Column Decoration Models Design and Ideas

3,478.20 lei 3,130.38 lei

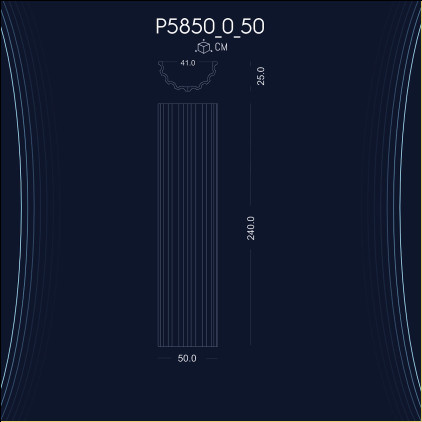

Versatile Design with Polyurethane Fluted Columns P5850_0_50: Ideas and Examples for Decorative Models

1,596.10 lei 1,436.49 lei

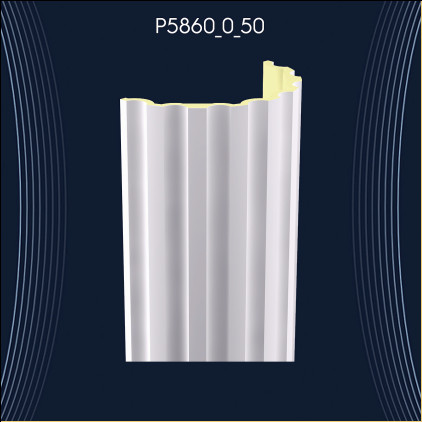

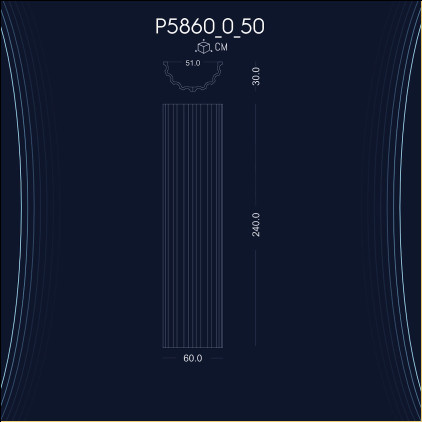

Polyurethane Fluted Columns P5860: Focusing on Elegance and Design Elements in Architecture - Decoration Models, Design Ideas and Inspirations

4,057.90 lei 3,652.11 lei

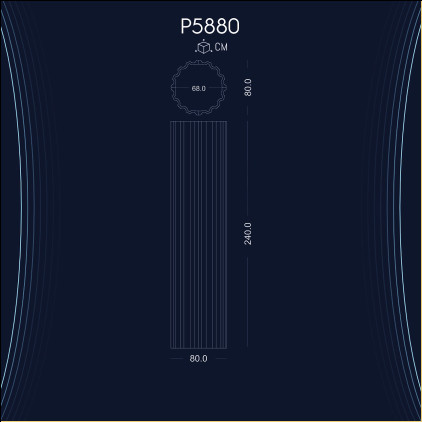

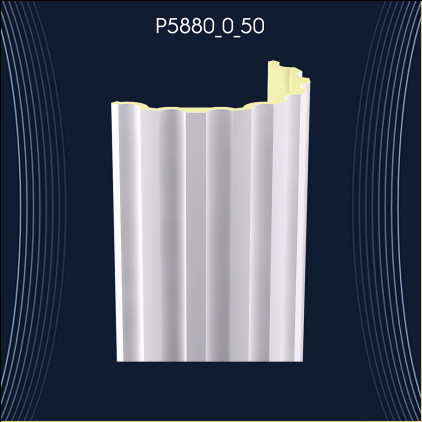

Easy Installation Polyurethane Grooved Columns P5880 - Cost-Effective Decoration Models Design and Ideas

6,886 lei 6,197.40 lei

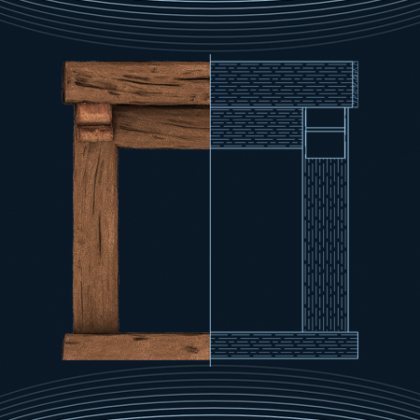

A polyurethane exterior jamb catalog is a collection showcasing various designs and styles of door frames made from polyurethane, suitable for outdoor use.

The polyurethane exterior jamb catalog is an extensive collection showcasing the latest in door frame technology and design. Polyurethane, known for its durability and resistance to weather conditions, makes for an excellent material in the construction of exterior door jambs. This catalog is designed to assist homeowners, builders, and architects in selecting the perfect jamb for their exterior doors, ensuring both aesthetic appeal and long-lasting functionality. Polyurethane exterior jambs offer numerous benefits over traditional materials such as wood or metal. These include: When selecting a polyurethane exterior jamb from the catalog, consider the following factors: The polyurethane exterior jamb catalog offers a wide range of options for those looking to enhance the durability, aesthetic, and energy efficiency of their exterior doors. With its numerous benefits and design flexibility, polyurethane is an excellent choice for exterior door jambs. Whether you are building a new home or upgrading your existing one, the polyurethane exterior jamb catalog provides all the information needed to make an informed decision.Polyurethane Exterior Jamb Catalog

Benefits of Polyurethane Exterior Jambs

Choosing the Right Jamb

Conclusion

The Exterior jamb catalog holds a position in history.

The history of architecture is replete with various tools and resources that have helped shape the built environment as we know it today. Among these, exterior jamb catalogs hold a unique place, offering insight into the design and construction practices of the past. These catalogs, often published by architectural firms or building material suppliers, provided a comprehensive overview of available designs, materials, and techniques for constructing door and window frames—elements crucial to the aesthetics and functionality of buildings. The origins of exterior jamb catalogs can be traced back to the late 19th and early 20th centuries, a period marked by rapid industrialization and advancements in printing technology. These factors combined to make the production and distribution of catalogs both feasible and economically viable. As a result, exterior jamb catalogs became an essential tool for architects, builders, and homeowners, facilitating easier decision-making in the selection of architectural details. Exterior jamb catalogs did more than just sell products; they influenced architectural styles and homeowner preferences across different periods. By disseminating a wide range of styles and options, these catalogs played a pivotal role in the popularization of architectural movements such as Art Deco, Craftsman, and Colonial Revival. Furthermore, they democratized access to design, allowing people of varied economic backgrounds to incorporate sophisticated architectural elements into their homes. Today, exterior jamb catalogs are valuable resources for historians, architects, and conservationists. They offer a window into the architectural trends, materials, and technologies of the past. Preservationists use these catalogs to accurately restore historic buildings, ensuring that any replacements or repairs remain true to the original design. Similarly, scholars study these catalogs to understand the evolution of architectural practices and the socio-economic factors that influenced them.The Historical Significance of Exterior Jamb Catalogs

Origin and Evolution

Cultural and Architectural Impact

Preservation and Study

Polyurethane exterior door frames are designed for durability and resistance to elements. They do not rot, warp, or split like wood, making them ideal for outdoor use. These frames can easily be painted or stained to match any decor, offering flexibility in design. Their insulation properties can also improve energy efficiency in homes.

Polyurethane exterior jambs are becoming increasingly popular in modern construction due to their durability, versatility, and aesthetic appeal. These jambs are designed to withstand the elements, providing excellent resistance to moisture, decay, and insect damage. Below, we explore the key properties and benefits of polyurethane exterior jambs. Polyurethane is known for its exceptional durability. Exterior jambs made from polyurethane are resistant to warping, cracking, and splitting, unlike traditional wood jambs. This material is also impervious to moisture, making it ideal for use in areas exposed to the elements. Its resistance to decay and insects further extends the lifespan of polyurethane jambs, making them a cost-effective solution for exterior door installations. One of the significant advantages of polyurethane exterior jambs is their energy efficiency. Polyurethane is an excellent insulator, helping to reduce heat transfer and improve the energy efficiency of buildings. This can lead to lower heating and cooling costs, making polyurethane jambs an eco-friendly choice for environmentally conscious homeowners and builders. Polyurethane jambs offer a wide range of design options. They can be manufactured in various styles and finishes, mimicking the look of natural wood or other materials. This versatility allows for greater design flexibility, enabling architects and designers to achieve the desired aesthetic without compromising on durability or performance. Another benefit of polyurethane exterior jambs is their ease of installation and maintenance. These jambs are lightweight and can be easily cut and shaped on-site, reducing installation time and costs. Additionally, polyurethane does not require the regular maintenance that wood does, such as painting or staining, to maintain its appearance and performance over time. Polyurethane exterior jambs offer a compelling combination of durability, energy efficiency, aesthetic flexibility, and ease of maintenance. Their resistance to moisture, decay, and insects makes them an ideal choice for exterior door installations in any climate. With the added benefits of energy savings and design versatility, polyurethane jambs are an excellent choice for both residential and commercial construction projects.Polyurethane Exterior Jamb Properties

Durability and Resistance

Energy Efficiency

Aesthetic Flexibility

Easy Installation and Maintenance

Conclusion

Are the applications of polyurethane exterior trim decorations distinct?

Polyurethane, a highly versatile material, has found its way into numerous applications, particularly in the realm of exterior jamb catalog decoration. This synthetic polymer, known for its exceptional durability and resistance to environmental factors, is ideal for outdoor applications. The usage areas of polyurethane in exterior jamb decoration are diverse, catering to both functional and aesthetic needs. One of the primary reasons for the widespread use of polyurethane in exterior jamb decoration is its remarkable durability and resistance to weather elements. Polyurethane coatings protect wooden jambs from moisture, UV rays, and temperature fluctuations, significantly extending their lifespan. Polyurethane can be molded into various shapes and designs, offering endless possibilities for aesthetic enhancement in exterior jamb decoration. From traditional to contemporary designs, polyurethane allows for the creation of intricate details and finishes that mimic the look of more expensive materials like wood and stone. When used as an insulating material in exterior jambs, polyurethane contributes to energy efficiency. Its excellent insulation properties help in reducing heat loss, thereby decreasing energy consumption and utility bills. The ease of maintenance is another significant advantage of using polyurethane in exterior jamb decoration. Unlike natural materials that require regular upkeep, polyurethane surfaces are easy to clean and maintain, needing only occasional wiping to keep them looking new. The usage areas of polyurethane in exterior jamb catalog decoration are indeed varied, covering aspects of durability, aesthetics, energy efficiency, and maintenance. Its adaptability and resilience make polyurethane an excellent choice for enhancing the exterior appeal and functionality of buildings. As technology and material science continue to advance, the potential applications of polyurethane in exterior decoration are set to expand even further, promising even more innovative and efficient solutions for architects and homeowners alike.Exploring the Versatile Usage Areas of Polyurethane in Exterior Jamb Catalog Decoration

Durability and Weather Resistance

Aesthetic Flexibility

Energy Efficiency

Easy Maintenance

Conclusion

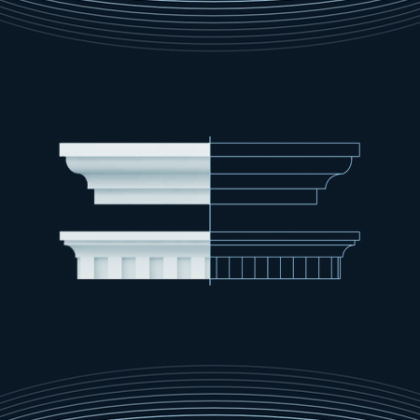

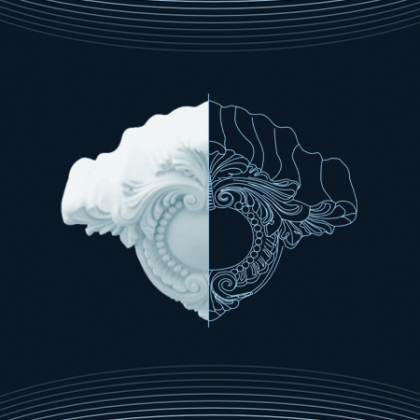

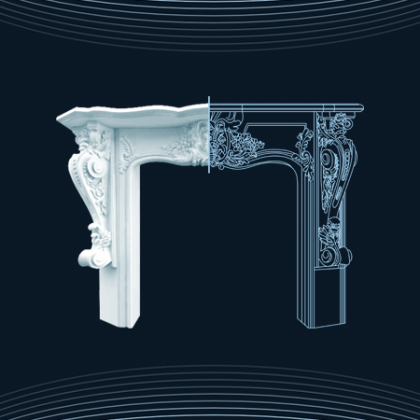

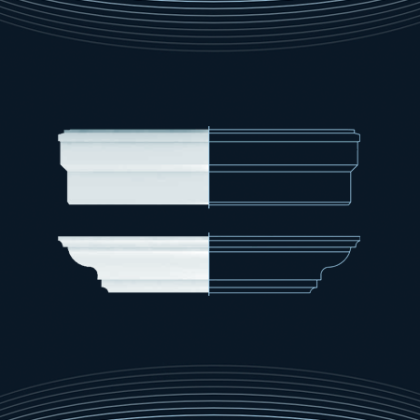

Models of Polyurethane Exterior Door Frames Catalog

When it comes to enhancing the durability and aesthetic appeal of exterior door frames, polyurethane exterior jambs are a top choice among homeowners and contractors alike. These jambs are designed to withstand the elements, providing a long-lasting solution that requires minimal maintenance. In this article, we'll explore the various models available in the polyurethane exterior jamb catalog, helping you make an informed decision for your next project. Polyurethane exterior jambs offer several advantages over traditional materials like wood or metal. Firstly, they are highly resistant to moisture, rot, and insect damage, making them ideal for use in any climate. Additionally, polyurethane is a lightweight material, which makes the installation process much easier and quicker. These jambs also come in a variety of styles and finishes, allowing for customization to fit any architectural design. The polyurethane exterior jamb catalog features a wide range of models to suit different needs and preferences. Some of the popular models include: Selecting the right polyurethane exterior jamb model depends on several factors, including the style of your home, the climate in your area, and your personal preferences. It's important to consider the overall aesthetic you wish to achieve, as well as the level of maintenance you're willing to undertake. Consulting with a professional can also provide valuable insights and recommendations tailored to your specific needs. Polyurethane exterior jambs are a versatile and durable option for enhancing the functionality and appearance of your home's exterior. With a variety of models available, you can easily find a solution that meets your aesthetic and practical requirements. By choosing the right model, you'll enjoy a beautiful and long-lasting exterior door frame that adds value to your property.Polyurethane Exterior Jamb Catalog Models

Benefits of Polyurethane Exterior Jambs

Model Varieties

Choosing the Right Model

Conclusion

Can a catalog of polyurethane exterior door frames be used on outside walls?

When it comes to enhancing the durability and aesthetic appeal of exterior walls, homeowners and builders often look for reliable and versatile materials. One such material that has gained popularity is polyurethane, especially in the form of exterior jambs. But the question arises, can polyurethane exterior jamb catalog be used on exterior walls effectively? Polyurethane exterior jambs are architectural elements designed to frame windows and doors, providing a seamless transition between different materials and enhancing the overall appearance of a building. Made from high-density polyurethane, these jambs are not only lightweight but also highly resistant to moisture, decay, and insect damage, making them ideal for exterior applications. While polyurethane exterior jambs offer numerous benefits, there are a few considerations to keep in mind. It's important to ensure proper installation to avoid gaps that could allow water ingress. Additionally, while polyurethane is durable, it may require painting or sealing to maintain its appearance and resistance to UV light over time. In conclusion, polyurethane exterior jamb catalogs can indeed be used on exterior walls, providing a durable, moisture-resistant, and aesthetically pleasing solution. Whether you're building a new home or renovating an existing one, incorporating polyurethane jambs can enhance the longevity and beauty of your exterior walls. As with any building material, ensure proper installation and maintenance to maximize the benefits of polyurethane exterior jambs.Using Polyurethane Exterior Jamb Catalog on Exterior Walls

Understanding Polyurethane Exterior Jambs

Benefits of Using Polyurethane Exterior Jambs on Exterior Walls

Considerations for Using Polyurethane Exterior Jambs

Conclusion

Can the catalog for exterior door frames made of polyurethane be painted?

When it comes to home improvement and construction projects, the finishing touches can make all the difference. One such detail is the exterior door jamb. Polyurethane exterior jambs have become increasingly popular due to their durability and resistance to rot and insects. However, homeowners and contractors often wonder if these polyurethane components can be painted to match the exterior design and color scheme of the home. Yes, polyurethane exterior jambs can be painted. Painting polyurethane jambs not only allows you to match them with the exterior color of your home but also provides an additional layer of protection against the elements. Before painting, it is crucial to properly prepare the surface of the polyurethane jamb. This involves cleaning the jamb thoroughly to remove any dirt, grease, or mildew. Once clean, lightly sanding the surface with fine-grit sandpaper will help the paint adhere better. After sanding, be sure to remove all dust with a tack cloth or a damp rag to ensure a smooth finish. For the best results, use a high-quality acrylic latex paint designed for exterior use. These paints are durable and flexible, which is important for materials like polyurethane that may expand and contract with temperature changes. Applying a primer designed for use on plastic materials can also improve adhesion and overall durability of the paint job. When painting polyurethane jambs, it's advisable to apply multiple thin coats of paint rather than a single thick coat. This method helps prevent drips and ensures a more even coverage. Allow each coat to dry thoroughly before applying the next. Depending on the paint and conditions, this could take anywhere from a few hours to overnight. With proper preparation and the right materials, painting polyurethane exterior jambs is not only possible but can also enhance the aesthetic appeal of your home's exterior while adding an extra layer of protection. Whether you're a professional contractor or a DIY enthusiast, painting polyurethane jambs can be a rewarding project that contributes to the overall beauty and durability of your home.Can Polyurethane Exterior Jamb Catalog Be Painted?

The Short Answer

Preparation is Key

Choosing the Right Paint

Application Tips

Conclusion

How to apply polyurethane on an exterior door frame guide?

Applying polyurethane to exterior door jambs can significantly enhance their durability and resistance to weather elements. Here's a step-by-step guide to ensure a successful application: Applying polyurethane to your exterior door jambs not only protects them from the elements but also enhances their appearance, making them look new for years to come. Be sure to follow these steps carefully for the best results.How to Apply Polyurethane on Exterior Door Jambs

Materials Needed

Steps to Apply Polyurethane on Exterior Door Jambs

The difference between a polyurethane exterior jamb catalog and a styrofoam exterior jamb catalog is the material used. Polyurethane is a durable, synthetic material, while styrofoam is a lighter, foam-based material.

When it comes to choosing materials for exterior door jambs, two popular options are polyurethane and styrofoam. Both materials offer distinct advantages and disadvantages, making them suitable for different applications and preferences. Polyurethane exterior jambs are known for their durability and strength. They are resistant to warping, cracking, and rotting, making them an excellent choice for areas exposed to harsh weather conditions. Polyurethane is also resistant to insects and pests, ensuring a longer lifespan for your door jamb. Aesthetically, polyurethane can be molded into various designs, allowing for more decorative options. However, polyurethane exterior jambs can be more expensive than other materials, including styrofoam. Styrofoam exterior jambs, on the other hand, are lightweight and cost-effective. They offer good insulation properties, which can help in reducing energy costs by keeping heat or cool air inside the home. Styrofoam is easy to install due to its lightweight nature, making it a good option for DIY projects. However, styrofoam is not as durable as polyurethane and can be susceptible to damage from impacts or pests. It also offers limited aesthetic options compared to polyurethane. In conclusion, the choice between polyurethane and styrofoam exterior jambs depends on your specific needs and preferences. If durability, resistance to elements, and aesthetic flexibility are your priorities, polyurethane is the way to go. On the other hand, if you are looking for a more cost-effective, lightweight, and insulating option, styrofoam could be the ideal choice. Consider the pros and cons of each material to make the best decision for your home.Differences Between Polyurethane and Styrofoam Exterior Jambs

Polyurethane Exterior Jambs

Styrofoam Exterior Jambs

Conclusion

The difference lies in the materials used for the exterior door frames listed in the catalogs. Polyurethane exterior jamb catalogs feature door frames made of polyurethane, a type of plastic. Plaster exterior jamb catalogs offer door frames made of plaster.

When it comes to choosing materials for exterior door jambs, two popular options are polyurethane and plaster. Both materials offer distinct advantages and disadvantages, making them suitable for different applications and preferences. This article explores the key differences between polyurethane and plaster exterior jambs. Polyurethane is a type of plastic that is highly versatile and can be formulated to be rigid or flexible. It is known for its durability and resistance to weather elements, making it an ideal choice for exterior applications. Plaster, on the other hand, is a mixture of water, sand, and a binder like lime or gypsum. It has been used for centuries in building construction and decorative elements due to its workability and finish. Polyurethane jambs are highly durable and resistant to rot, mold, and mildew, making them low maintenance. They can withstand harsh weather conditions without cracking or warping. Plaster jambs, while durable, require more maintenance to ensure their longevity. They are more susceptible to weather-induced wear and tear, such as cracking and erosion, and may need regular repairs and repainting. Installing polyurethane jambs is relatively straightforward due to their lightweight and easy-to-cut nature. They can also be molded into various designs, offering more flexibility in terms of aesthetics. Plaster requires a more skilled installation process, as it needs to be mixed and applied on-site. However, this allows for a high degree of customization in terms of shapes and textures, making it ideal for historic restorations or custom designs. Polyurethane is a synthetic material that is not biodegradable, which can be a concern for environmentally conscious consumers. However, its durability means it does not need to be replaced often, potentially reducing waste over time. Plaster is more eco-friendly, being made from natural materials. It is also breathable, contributing to healthier indoor air quality. However, its production process can be energy-intensive. Choosing between polyurethane and plaster exterior jambs depends on several factors, including durability, maintenance, installation, customization options, and environmental impact. Polyurethane offers a low-maintenance, durable solution with flexible design options, while plaster provides a more natural, customizable option with a higher maintenance requirement. Ultimately, the best choice depends on the specific needs and values of the homeowner or builder.Difference Between Polyurethane and Plaster Exterior Jambs

Introduction

Material Composition

Durability and Maintenance

Installation and Customization

Environmental Impact

Conclusion

Polyurethane precast is made from a type of plastic that's strong and lightweight. GRC precast, or Glass Reinforced Concrete, combines cement with glass fibers for added strength.

Difference Between Polyurethane Precast and GRC Precast

In the world of construction and architectural design, materials play a pivotal role in determining the efficiency, durability, and aesthetic appeal of structures. Among the myriad of options available, polyurethane precast and Glassfibre Reinforced Concrete (GRC) precast stand out for their unique properties and applications. Understanding the differences between these two materials can help architects, builders, and developers make informed decisions.

What is Polyurethane Precast?

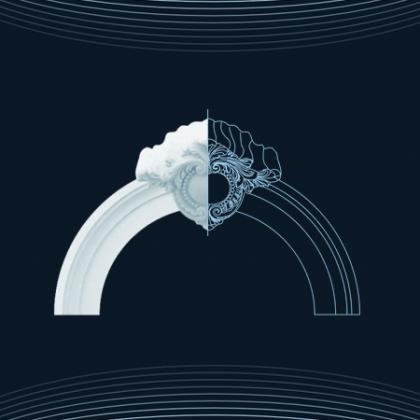

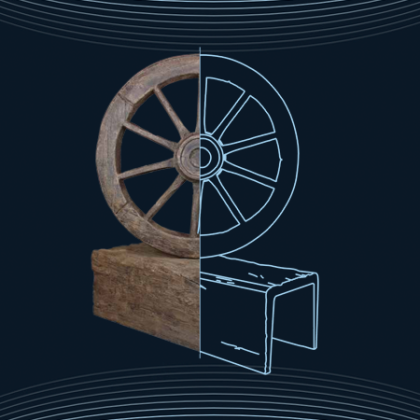

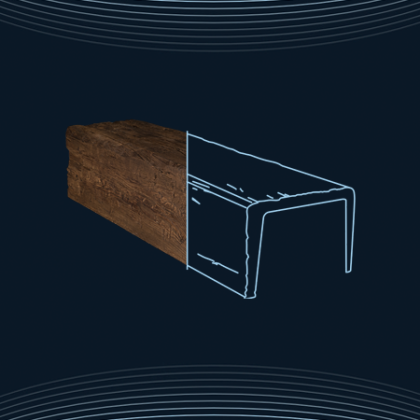

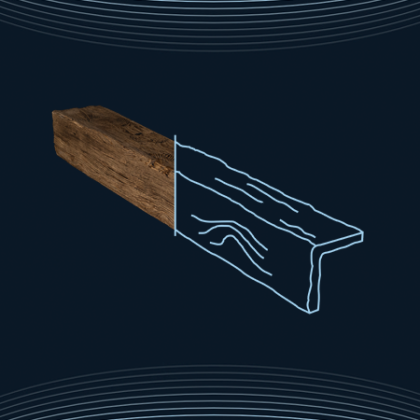

Polyurethane precast refers to the use of polyurethane, a type of polymer, in the creation of building components that are cast in a reusable mold or form. This material is known for its lightweight, insulation properties, and flexibility in design. Polyurethane can mimic the appearance of more traditional materials like wood, stone, or brick, while offering enhanced durability and resistance to weather and pests.

What is GRC Precast?

GRC precast, or Glassfibre Reinforced Concrete, combines cement, fine aggregate, water, chemical admixtures, and glass fibers to create a material that is both strong and lightweight. GRC is particularly noted for its ability to be molded into thin, yet durable panels with a wide variety of shapes and textures. It offers significant advantages in terms of strength-to-weight ratio, fire resistance, and environmental impact.

Main Differences

- Material Composition: Polyurethane precast is primarily made of polymer, whereas GRC precast is a composite of cement and glass fibers.

- Weight: Polyurethane elements tend to be lighter than GRC, making them easier to transport and install.

- Insulation: Polyurethane provides superior insulation properties compared to GRC, making it a better choice for energy-efficient building designs.

- Durability: While both materials are durable, GRC's cementitious nature gives it an edge in terms of resistance to fire and environmental wear and tear.

- Aesthetic Flexibility: Both materials offer great flexibility in design, but polyurethane can more easily mimic the look of other materials.

Conclusion

The choice between polyurethane precast and GRC precast depends on the specific requirements of a project, including considerations of weight, insulation, durability, and aesthetic preferences. By weighing the advantages and limitations of each material, stakeholders can select the most suitable option for their construction or architectural needs.

Polyurethane Exterior Door Frame Prices

When it comes to selecting the best materials for exterior door frames, polyurethane exterior jambs stand out for their durability, resistance to weather conditions, and low maintenance requirements. Whether you are a contractor, architect, or homeowner, understanding the pricing of polyurethane exterior jambs is crucial for planning your construction or renovation projects. Polyurethane exterior jambs are manufactured from a type of plastic that is highly resistant to wear, tear, and environmental factors. This makes them an ideal choice for exterior door frames, as they can withstand harsh weather conditions without rotting, warping, or deteriorating. Additionally, their low maintenance needs make them a cost-effective option in the long run. The prices of polyurethane exterior jambs can vary based on several factors, including: The prices for polyurethane exterior jambs can range significantly based on the above factors. As of the latest market analysis, prices can vary from as low as $50 for basic models to over $200 for premium, custom-designed options. It's important to note that these prices are subject to change based on market conditions and should be used as a general guide. Polyurethane exterior jambs offer an excellent balance of durability, aesthetic appeal, and cost-effectiveness for exterior door installations. By understanding the factors that influence their prices, you can make informed decisions that fit your budget and project requirements. Always consult with suppliers or manufacturers for the most accurate and up-to-date pricing information.Polyurethane Exterior Jamb Catalog Prices

Understanding Polyurethane Exterior Jambs

Factors Influencing Prices

Price Range

Conclusion

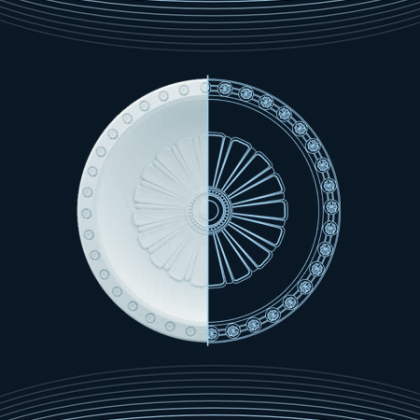

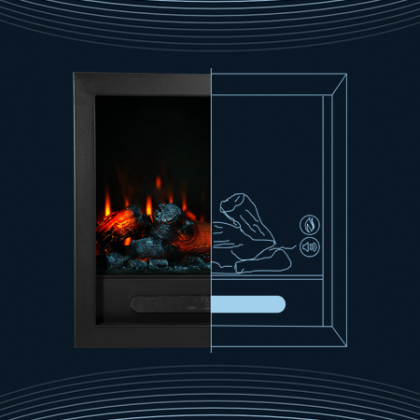

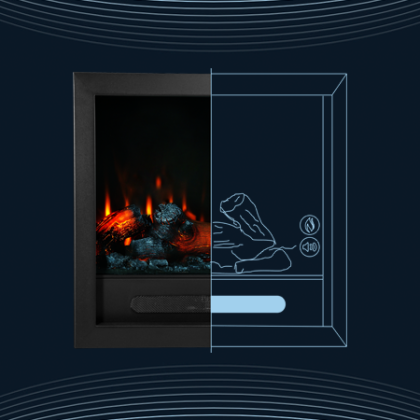

Information Gallery

List of detailed descriptions of images in the image gallery.

English

English

Romanian

Romanian