Polyurethane hotel exterior designs refer to the use of polyurethane materials in the outer design of hotels. Polyurethane, a type of plastic, is used for its durability, insulation properties, and versatility in mimicking different textures and materials. This allows for various architectural styles and efficient energy use in hotels.

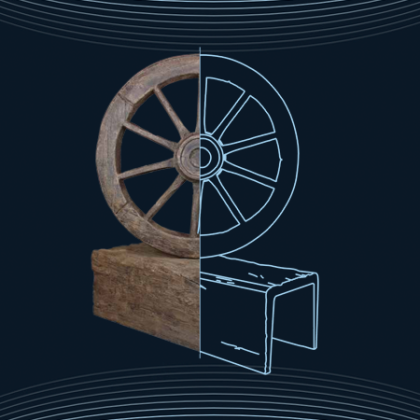

Polyurethane, a versatile and durable material, has found a significant place in the construction and design of hotel exteriors. Its unique properties make it an ideal choice for creating innovative and sustainable designs that stand out. This article explores the application of polyurethane in hotel exterior designs, its benefits, and the trends shaping its use in the hospitality industry. Polyurethane is celebrated for its durability, flexibility, and resistance to weather conditions, making it perfect for outdoor applications. Its ability to mimic the appearance of more traditional materials like wood and stone, while offering superior performance in terms of maintenance and longevity, has made it a favorite among architects and designers. In hotel design, polyurethane is used in a variety of ways. From façade panels and decorative elements to waterproofing and insulation, its versatility allows for creative and functional exterior designs. Polyurethane can be molded into intricate patterns for decorative trims, or used in large panels that provide excellent thermal insulation and soundproofing, enhancing guest comfort. The trend towards eco-friendly and sustainable construction materials has seen an increased use of polyurethane in hotel exteriors. Its energy-efficient qualities align with the growing demand for green building practices. Moreover, the push for unique architectural identities has driven the adoption of polyurethane in creating distinctive and memorable hotel designs that resonate with guests and enhance the overall aesthetic appeal of the hospitality industry. In conclusion, polyurethane offers a blend of functionality and design freedom that is transforming hotel exteriors. Its application in the hospitality industry underscores a commitment to durability, sustainability, and architectural innovation. As the industry evolves, polyurethane is set to play a pivotal role in shaping the future of hotel design.Polyurethane Hotel Exterior Designs

Why Polyurethane?

Applications in Hotel Exteriors

Benefits of Polyurethane in Hotel Design

Trends in Polyurethane Hotel Exteriors

The role of hotel exterior designs in history.

Hotel exterior designs have played a pivotal role in architectural history, reflecting the cultural, social, and economic trends of their times. From the grandiose structures of the 19th century to the minimalist approaches of the modern era, the evolution of hotel designs is a mirror to the world's progression. This article explores the place of hotel exterior designs in history, highlighting their significance and transformation over the years. The 19th century marked the beginning of luxurious hotel constructions, characterized by elaborate designs and extravagant decorations. Hotels like The Waldorf Astoria in New York and The Ritz in Paris became symbols of opulence, showcasing the wealth and status of their guests. These architectural marvels were not just places to stay; they were landmarks that embodied the pinnacle of social prestige and architectural innovation of their time. The 1920s introduced Art Deco, a style that brought geometric shapes, vibrant colors, and exotic materials to hotel exteriors. This era's iconic hotels, such as the Miami Beach's Art Deco Historic District, stood as testaments to the optimism and economic prosperity of the post-war period. The flamboyant style of these buildings reflected the societal shift towards modernity and the celebration of technological and cultural advancements. After World War II, hotel design took a turn towards minimalism and functionality, influenced by the Modernist movement. The emphasis was on clean lines, simple forms, and the integration of new materials like steel and glass. This period saw the rise of skyscraper hotels in urban centers, symbolizing the post-war economic boom and the rapid urbanization of cities. The simplicity and efficiency of these designs represented a departure from the past's extravagance, focusing instead on practicality and accessibility. In the late 20th century, the boutique hotel movement emerged as a response to the homogeneity of hotel designs. These small, often independently owned hotels offered unique and personalized experiences, with exteriors that blended with local architecture or stood out through avant-garde designs. This trend highlighted the growing desire for authenticity and individuality in travel experiences, marking a significant shift in consumer preferences. Hotel exterior designs are more than just the façade of a building; they are a reflection of the cultural, economic, and technological zeitgeist of their eras. From the opulent structures of the 19th century to the sleek and minimalist designs of today, the evolution of hotel architecture tells the story of society's changing values and aspirations. As we move forward, the history of hotel design will continue to evolve, mirroring the dynamic nature of human progress.The Historical Significance of Hotel Exterior Designs

The Grandeur of the 19th Century

Art Deco and the Roaring Twenties

Post-War Modernism

The Boutique Hotel Movement

Conclusion

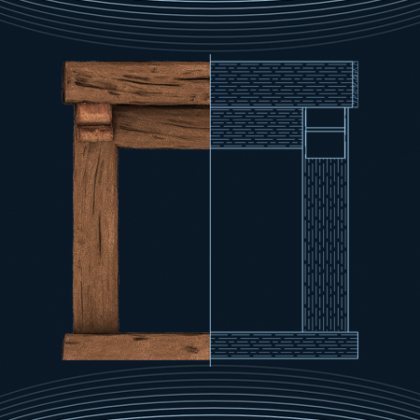

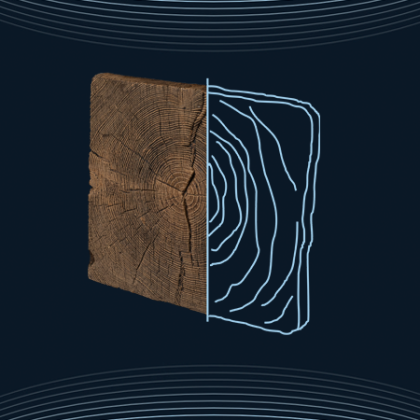

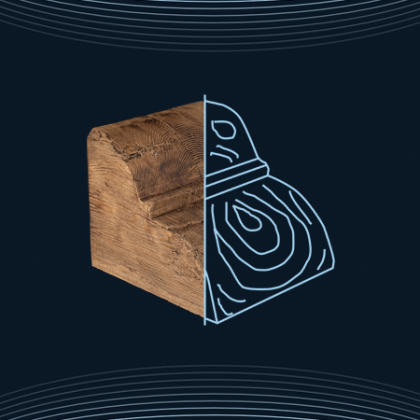

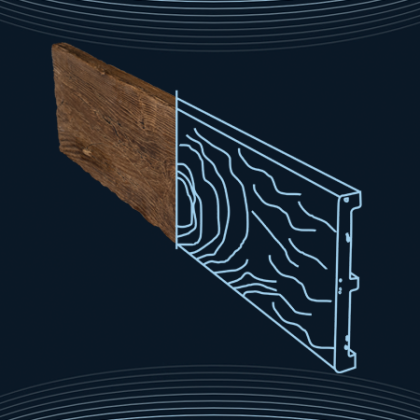

Designs of hotel exteriors made of polyurethane materials.

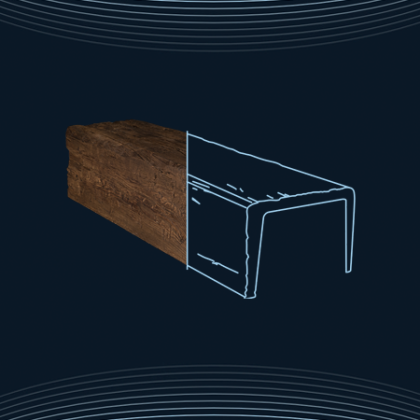

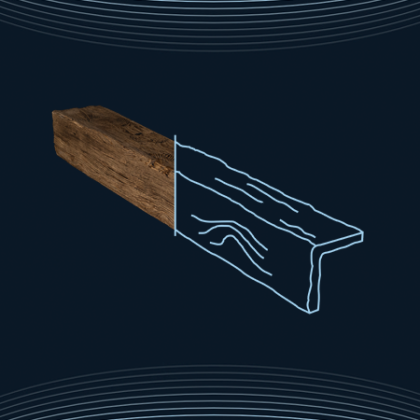

Polyurethane has emerged as a leading material in the construction and design of hotel exteriors, offering a range of properties that enhance both the aesthetic appeal and functionality of buildings. This versatile material is known for its durability, insulation properties, and ability to mimic the appearance of more traditional materials like wood, stone, and concrete. One of the most significant benefits of using polyurethane in hotel exterior designs is its durability. Polyurethane coatings are resistant to weathering, UV rays, and corrosion, making them an ideal choice for hotels located in harsh environmental conditions. This material can withstand extreme temperatures, maintaining its structural integrity and appearance over time, thus reducing maintenance costs and extending the lifespan of the building. Polyurethane also offers excellent insulation properties, which can significantly reduce energy costs for heating and cooling. By incorporating polyurethane panels or coatings in the hotel's exterior design, it is possible to enhance the building's thermal efficiency, leading to a more comfortable indoor environment for guests and reduced energy consumption. The aesthetic flexibility of polyurethane is another key advantage. It can be molded into a variety of shapes and textures, and painted in any color, allowing architects and designers to achieve a wide range of looks. Whether the goal is to mimic the appearance of natural materials or create a modern, innovative facade, polyurethane provides the versatility needed to realize any design vision. Finally, polyurethane is considered a more environmentally friendly option compared to some traditional building materials. It contributes to the reduction of CO2 emissions through its insulation properties and is often produced with eco-friendly processes. Moreover, the longevity and low maintenance requirements of polyurethane reduce the need for frequent replacements and repairs, further minimizing the environmental impact. In conclusion, polyurethane hotel exterior designs offer a combination of durability, energy efficiency, aesthetic versatility, and reduced environmental impact, making it an attractive choice for modern hotel construction and renovations. As the hospitality industry continues to evolve, the use of innovative materials like polyurethane is set to play a key role in shaping the future of hotel design.Polyurethane Hotel Exterior Designs

Durability and Longevity

Insulation Properties

Aesthetic Flexibility

Environmental Impact

Yes, the uses of polyurethane in hotel exterior designs are distinct.

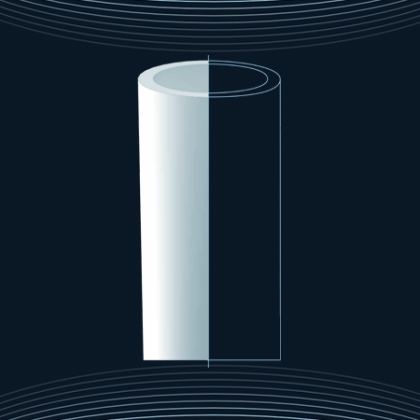

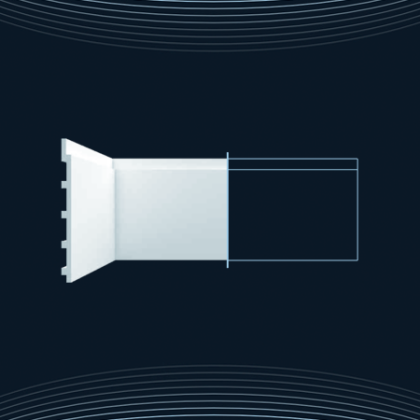

Polyurethane, a highly versatile material, has been increasingly used in various applications, including hotel exterior designs. Its usage areas in hotel exterior decorations are diverse, catering to different design needs and aesthetic preferences. This article delves into how polyurethane is utilized in hotel exteriors, showcasing its adaptability and functionality.

One of the primary reasons for choosing polyurethane in hotel exterior designs is its exceptional weather resistance. Hotels, aiming to maintain their aesthetic appeal and structural integrity against various climatic conditions, find polyurethane an ideal choice. This material can withstand extreme temperatures, UV exposure, and moisture, ensuring the exterior decorations remain intact and vibrant over the years.

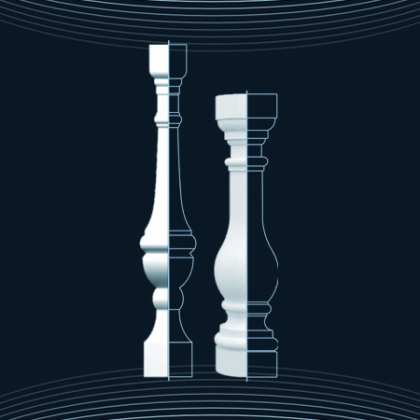

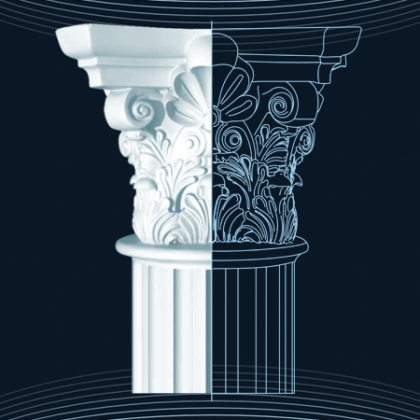

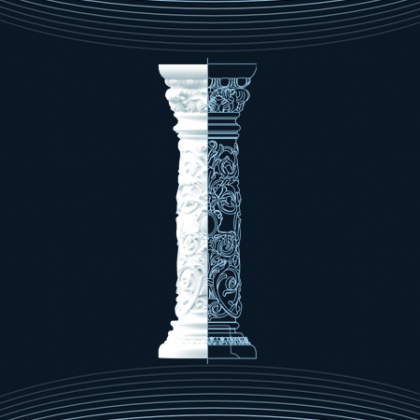

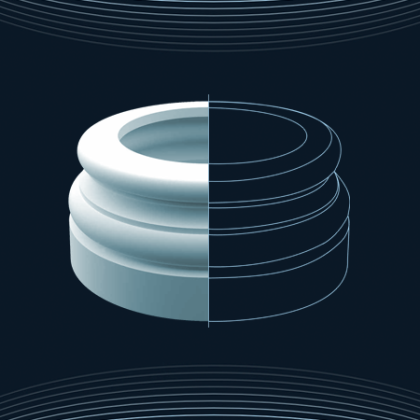

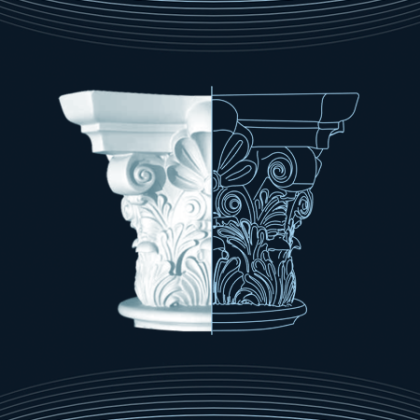

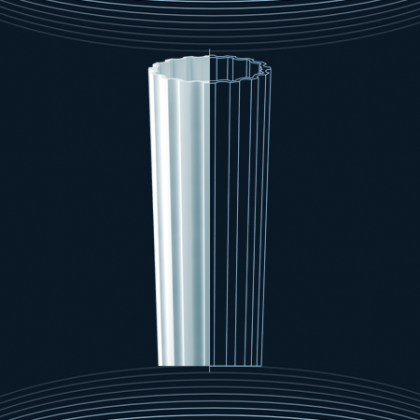

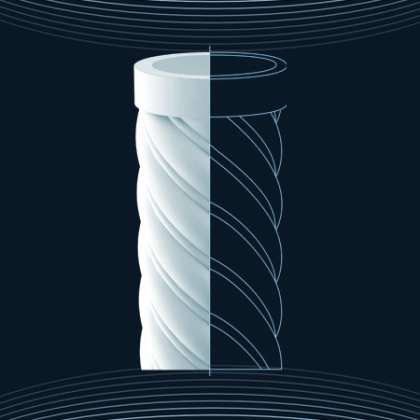

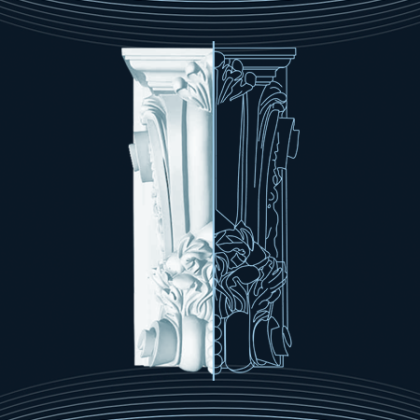

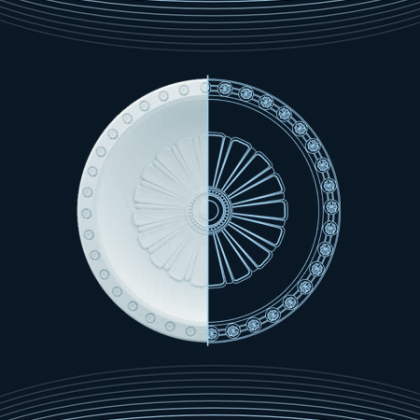

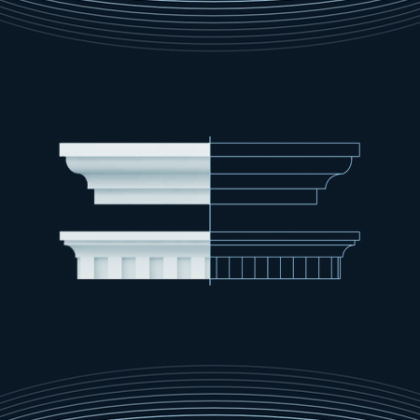

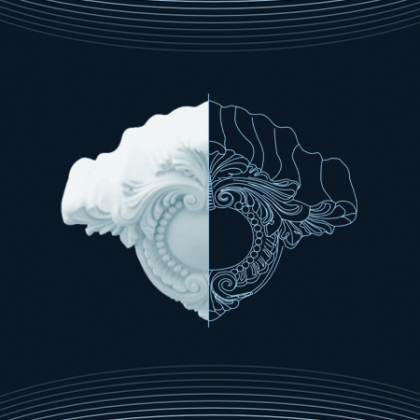

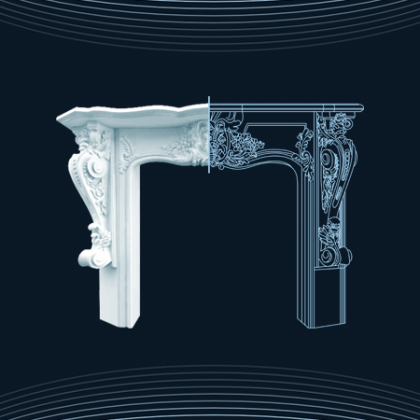

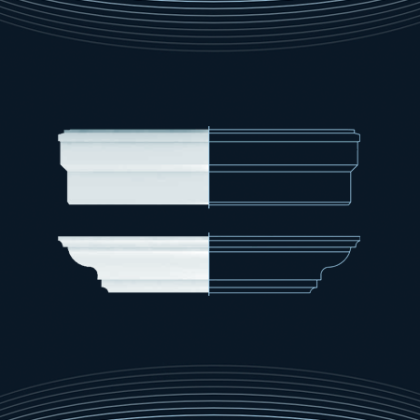

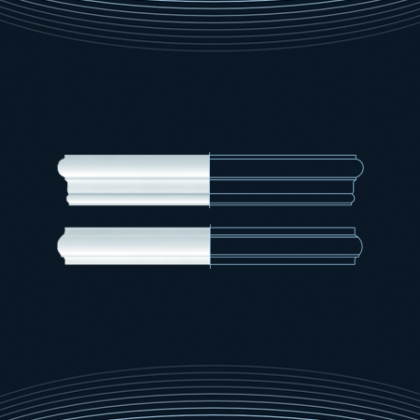

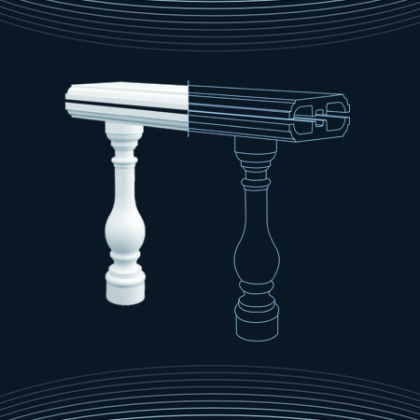

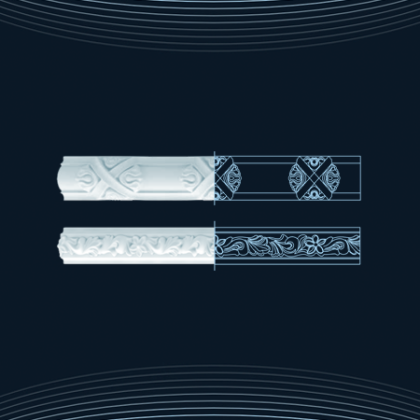

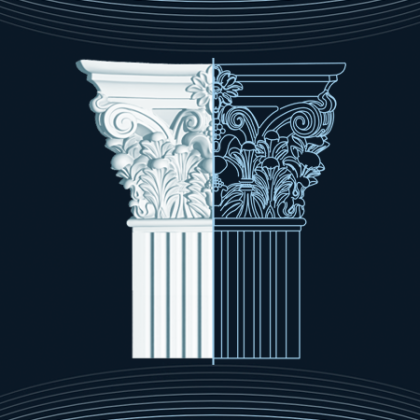

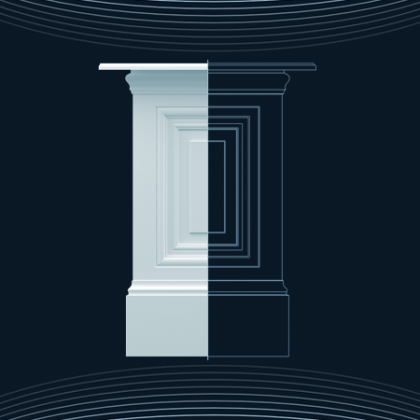

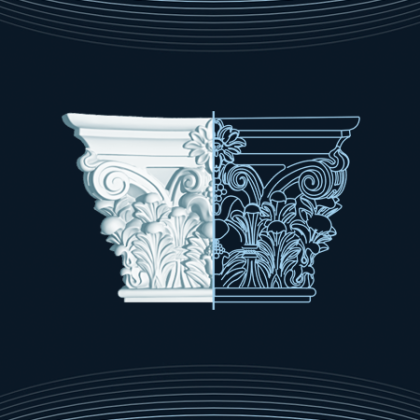

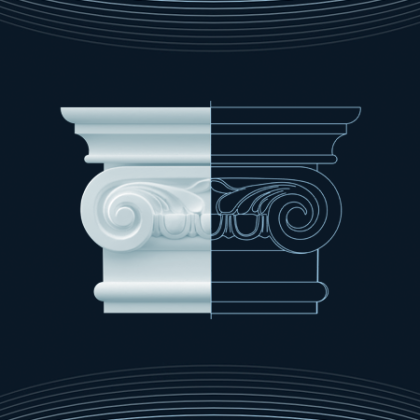

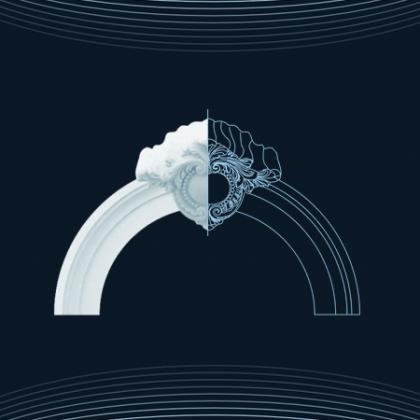

Polyurethane can be molded into intricate designs and patterns, making it suitable for creating decorative elements that enhance a hotel's architectural aesthetics. From ornate facades to elegant cornices and moldings, polyurethane allows for a high degree of customization. This flexibility enables hoteliers to achieve a unique exterior look that can range from classic elegance to modern sophistication.

Beyond its aesthetic versatility, polyurethane also contributes to the energy efficiency of hotel buildings. Its insulating properties help in reducing heat loss or gain, thereby lowering energy consumption for heating or cooling. This aspect is particularly beneficial for hotels looking to minimize their environmental impact and operational costs.

Despite its numerous benefits, polyurethane remains a cost-effective solution for hotel exterior decoration. Its durability and low maintenance requirements reduce long-term upkeep costs. Additionally, the ease of installation and the material's lightweight nature contribute to lower labor and transportation expenses, making it an economical choice for hoteliers.

The usage areas of polyurethane in hotel exterior designs are indeed separated by its multifaceted applications, ranging from enhancing architectural aesthetics to improving energy efficiency. Its weather resistance, durability, and cost-effectiveness make it a preferred choice for hoteliers aiming to achieve both functional and visually appealing exteriors. As the hotel industry continues to evolve, the role of polyurethane in exterior decorations is expected to grow, further highlighting its significance in modern architectural designs.

Exploring the Versatility of Polyurethane in Hotel Exterior Designs

Weather Resistance and Durability

Architectural Aesthetics

Energy Efficiency

Cost-Effectiveness

Conclusion

Designs for hotel exteriors made of polyurethane.

The use of polyurethane in hotel exterior designs has been a growing trend in the architecture and construction industry. This innovative material offers a range of benefits, from durability and insulation to aesthetic versatility, making it an ideal choice for modern hotel exteriors. Polyurethane is known for its exceptional durability. It withstands harsh weather conditions, including heavy rain, intense sunlight, and strong winds, without deteriorating. This resilience makes it a cost-effective choice for hotel exteriors, as it minimizes the need for frequent repairs and maintenance. One of the significant advantages of polyurethane is its excellent insulation properties. It helps in maintaining the interior temperature of the hotel, contributing to energy efficiency and reducing heating and cooling costs. This feature is particularly beneficial in regions with extreme weather conditions. Polyurethane can be molded into various shapes and designs, offering unparalleled aesthetic flexibility. It can mimic the appearance of traditional materials like wood, stone, or brick, while providing the benefits of modern technology. This allows architects and designers to create unique and visually appealing hotel exteriors that stand out. With an increasing focus on sustainability, polyurethane is also appreciated for its potential to reduce the environmental impact of construction projects. Its insulation properties can contribute to lower energy consumption, and its durability means less frequent replacements and repairs, leading to reduced waste. Polyurethane hotel exterior designs offer a blend of durability, efficiency, and aesthetic appeal, making them a popular choice in modern architecture. As the construction industry continues to evolve, the versatility and benefits of polyurethane are likely to make it a staple in hotel design.Polyurethane Hotel Exterior Designs

Durability and Maintenance

Insulation Properties

Aesthetic Flexibility

Environmental Impact

Conclusion

Can polyurethane be used for hotel outside walls?

In the quest for durable and aesthetically pleasing materials for hotel exteriors, polyurethane has emerged as a viable contender. Known for its versatility, durability, and ease of maintenance, polyurethane can indeed be used on exterior walls, including those of hotels. This article explores the feasibility, benefits, and considerations of using polyurethane in hotel exterior designs. Polyurethane is a synthetic material that can be formulated to meet various architectural requirements, including flexibility, hardness, and resistance to environmental factors. Its feasibility for use in hotel exteriors lies in its capability to withstand harsh weather conditions, resist fading from UV light, and repel water, making it an excellent choice for both protection and aesthetics. One of the key benefits of using polyurethane on hotel exterior walls is its durability. Unlike traditional materials that may crack, warp, or rot over time, polyurethane maintains its integrity, ensuring a long-lasting finish. Furthermore, its versatility allows for the creation of intricate designs and textures, enabling architects and designers to achieve a wide range of looks from classic to modern. While polyurethane offers numerous advantages, there are several considerations to keep in mind. The initial cost can be higher than some traditional materials, but this is often offset by its longevity and low maintenance requirements. Additionally, proper installation by experienced professionals is crucial to maximize its benefits and ensure the longevity of the hotel's exterior. Environmental impact is another consideration. While polyurethane is durable and long-lasting, it is a synthetic material derived from petroleum products. Therefore, selecting eco-friendly polyurethane options, which are increasingly available, can help mitigate environmental concerns. In conclusion, polyurethane is a suitable and beneficial material for hotel exterior walls, offering durability, versatility, and aesthetic appeal. By considering the initial investment, installation requirements, and environmental impact, hotel owners and designers can make informed decisions to enhance the appearance and longevity of their properties with polyurethane.Can Polyurethane Be Used on Hotel Exterior Walls?

Feasibility and Benefits

Considerations

Conclusion

Can polyurethane coatings used on hotel exteriors be painted over?

When it comes to renovating or refreshing the exterior appearance of a hotel, one question that often arises is whether polyurethane surfaces can be painted. Polyurethane is a popular material for hotel exteriors due to its durability and resistance to weather conditions. However, the need for aesthetic updates or brand alignment can necessitate a change in color or finish. This article explores the feasibility of painting polyurethane hotel exterior designs and provides tips for achieving the best results. The short answer is yes, polyurethane surfaces can be painted. However, the success of painting over polyurethane depends on the preparation process and the type of paint used. Proper preparation is key to ensuring that the new paint adheres well to the polyurethane surface and lasts for a long time. Before painting, it's crucial to prepare the polyurethane surface properly. Here are the essential steps: Not all paints are suitable for use on polyurethane. Acrylic latex paint or 100% acrylic paint is often recommended for painting polyurethane surfaces due to its flexibility and durability. These types of paint adhere well to primed polyurethane and can withstand the elements, making them ideal for exterior applications. For the best results, follow these application tips: Painting polyurethane hotel exterior designs is a viable way to update the appearance of a hotel. With proper preparation and the right materials, you can achieve a durable and aesthetically pleasing finish. Whether you're aiming for a bold color change or a subtle refresh, painting polyurethane surfaces can help enhance the overall look of your hotel property.Painting Polyurethane Hotel Exterior Designs

Can Polyurethane Be Painted?

Preparation Steps

Choosing the Right Paint

Application Tips

Conclusion

Applying polyurethane to hotel exteriors involves preparing the surface by cleaning and sanding, then applying the polyurethane with a brush or sprayer for a protective finish.

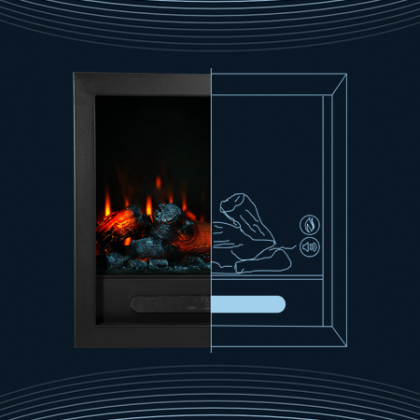

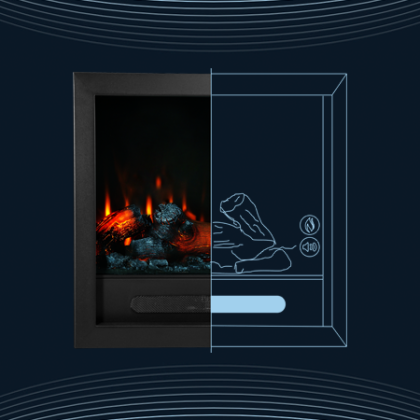

When it comes to enhancing and protecting the exterior design of a hotel, polyurethane is a material that stands out for its versatility and durability. It is a protective coating that can shield the hotel's exterior surfaces from weathering, UV damage, and wear, while also enhancing the aesthetic appeal of the structure. In this article, we will explore how to apply polyurethane in hotel exterior designs effectively. Before applying polyurethane, it's crucial to prepare the surface properly. This involves cleaning the exterior surfaces to remove any dirt, grime, or loose paint. If there are any cracks or damages, they should be repaired. A smooth, clean surface ensures better adhesion of the polyurethane coating. There are two main types of polyurethane - water-based and oil-based. Water-based polyurethane is easier to apply, dries faster, and has a lower odor, making it ideal for exterior applications where quick turnaround is essential. Oil-based polyurethane, on the other hand, is more durable and offers a richer finish, which might be preferable for luxury hotels seeking a high-end exterior appearance. Applying polyurethane can be done using a brush, roller, or sprayer, depending on the scale of the project and the desired finish. For large hotel exteriors, spraying is often the most efficient method. It's important to apply polyurethane in thin, even coats, allowing sufficient drying time between coats. This might vary depending on the product and weather conditions, so always refer to the manufacturer's instructions. After the final coat of polyurethane has been applied, it needs time to cure fully. This process can take several days, during which the hotel's exterior should be protected from dust, rain, and extreme temperatures. Once cured, the polyurethane coating will provide a durable, weather-resistant finish. Regular maintenance, such as cleaning and touch-ups, will ensure the longevity of the finish. In conclusion, applying polyurethane to hotel exteriors is a wise investment in the building's longevity and aesthetic appeal. By following these steps, hoteliers can achieve a protective and attractive exterior that welcomes guests for years to come.Applying Polyurethane in Hotel Exterior Designs

Step 1: Surface Preparation

Step 2: Choosing the Right Polyurethane

Step 3: Application

Step 4: Curing and Maintenance

Polyurethane hotel exterior designs use a type of durable plastic for decoration and insulation, offering a strong, weather-resistant finish. Styrofoam hotel exterior designs, on the other hand, utilize a lightweight foam for insulation and design, which is easier to shape but less durable and weather-resistant compared to polyurethane.

When it comes to hotel exterior designs, the materials used play a pivotal role in both aesthetics and functionality. Two popular materials for hotel exteriors are polyurethane and styrofoam. Although they may appear similar at first glance, they have distinct differences that can impact the choice for a hotel's exterior design. Polyurethane is a type of plastic material that is highly versatile and durable. It is often used in hotel exterior designs for its ability to mimic the appearance of more expensive and heavier materials like wood and stone. Polyurethane is resistant to weather, UV rays, and impact, making it an excellent choice for hotel exteriors that require longevity and minimal maintenance. It also provides better insulation than styrofoam, contributing to energy efficiency in hotel buildings. Styrofoam, or expanded polystyrene (EPS), is a lightweight, foam-like material. It is commonly used in the construction industry for insulation and as a lightweight fill material. In hotel exterior designs, styrofoam is often used for decorative elements due to its ease of shaping and carving. However, it is less durable than polyurethane and more susceptible to damage from physical impact and environmental factors. Styrofoam also offers lower resistance to UV rays and can degrade over time if not properly protected or maintained. In conclusion, while both polyurethane and styrofoam can be used in hotel exterior designs, they serve different purposes and offer varying benefits. Polyurethane is preferred for its durability, resistance to environmental factors, and energy efficiency, making it suitable for structural and decorative elements that require longevity. On the other hand, styrofoam is best suited for temporary structures or decorative elements that do not require high durability or resistance to environmental damage. The choice between the two materials should be based on the specific needs and goals of the hotel exterior design project.Difference Between Polyurethane and Styrofoam Hotel Exterior Designs

Polyurethane Hotel Exterior Designs

Styrofoam Hotel Exterior Designs

Conclusion

Polyurethane hotel exterior designs use a type of plastic for decoration and protection, offering durability and versatility. Plaster hotel exterior designs involve a mixture of lime, sand, and water, creating a classic and elegant look.

When it comes to designing the exterior of a hotel, the choice of materials plays a crucial role in defining its aesthetic appeal and durability. Two popular materials used in the facade design of hotels are polyurethane and plaster. Each material offers distinct advantages and characteristics, making them suitable for different design requirements and architectural styles. Polyurethane is a type of synthetic resin known for its exceptional durability and resistance to environmental factors. Hotel exteriors designed with polyurethane benefit from its lightweight nature, ease of installation, and minimal maintenance requirements. Polyurethane can be molded into a wide variety of shapes and designs, allowing for creative and intricate architectural details. It is also resistant to moisture, temperature changes, and UV radiation, making it an ideal choice for hotels in regions with harsh weather conditions. Plaster, on the other hand, is a traditional building material that has been used for centuries. It consists of a mixture of lime or gypsum, sand, and water, applied over metal lathing or masonry. Plaster hotel exterior designs offer a classic and timeless appeal, bringing a sense of warmth and elegance to the building. Plaster is highly versatile and can be finished in various textures and colors. However, it requires skilled labor for application and is more susceptible to cracking and damage from moisture compared to polyurethane. The choice between polyurethane and plaster for hotel exterior designs largely depends on the architectural style of the hotel, environmental considerations, and budget. Polyurethane is best suited for modern hotels requiring intricate designs and high durability, while plaster is ideal for classic or historic hotel designs that benefit from its natural texture and elegance. Ultimately, both materials can enhance the exterior of a hotel, but it is essential to consider their properties and limitations to make an informed decision.Difference Between Polyurethane and Plaster Hotel Exterior Designs

Polyurethane Exterior Designs

Plaster Exterior Designs

Choosing Between Polyurethane and Plaster

Polyurethane precast is made from a type of plastic that's strong and lightweight, used for decorative elements. GRC precast, or Glassfibre Reinforced Concrete, combines cement and glass fibers for a more durable and versatile product used in construction.

In the world of construction, materials play a crucial role in determining the efficiency, durability, and aesthetic appeal of a building. Among the various materials used, polyurethane precast and Glassfibre Reinforced Concrete (GRC) precast are prominent for their unique properties and applications. Understanding the difference between these two materials is essential for architects, builders, and developers to make informed decisions. Polyurethane precast refers to the use of polyurethane, a type of polymer, in the creation of building components off-site. These components are then transported to the construction site for assembly. Polyurethane is known for its lightweight, insulation properties, and versatility in shapes and finishes. It is often used for decorative elements, moldings, and panels that require fine detail and a smooth finish. GRC precast, or Glassfibre Reinforced Concrete precast, involves embedding glass fibers in a concrete matrix. This combination results in a material that is much lighter than traditional concrete but with enhanced strength and durability. GRC precast is widely used for cladding panels, architectural elements, and in situations where a lightweight yet strong material is required. In conclusion, both polyurethane precast and GRC precast have their advantages and specific applications in the construction industry. The choice between them depends on the requirements of the project, including factors such as weight, strength, insulation needs, and aesthetic goals. By understanding the distinct characteristics of each material, construction professionals can select the most appropriate option for their projects.Difference Between Polyurethane Precast and GRC Precast

What is Polyurethane Precast?

What is GRC Precast?

Key Differences

Hotel Exterior Designs with Polyurethane: Prices

Polyurethane Hotel Exterior Designs and Prices

The use of polyurethane in hotel exterior designs has become increasingly popular due to its durability, versatility, and aesthetic appeal. Polyurethane is a synthetic material that can be molded into various shapes and textures, making it an ideal choice for creating unique and attractive hotel exteriors. In this article, we will explore the benefits of using polyurethane in hotel exterior designs and provide an overview of the prices associated with these designs.

Benefits of Polyurethane in Hotel Exterior Designs

Polyurethane offers several benefits for hotel exteriors, including:

- Durability: Polyurethane is known for its durability and resistance to weather conditions, making it an excellent choice for hotel exteriors that need to withstand various environmental elements.

- Versatility: The material can be molded into a wide range of shapes and textures, allowing for creative and unique designs that can set a hotel apart from its competitors.

- Maintenance: Polyurethane exteriors are relatively easy to maintain, requiring only occasional cleaning to keep them looking their best.

- Energy Efficiency: Polyurethane can also provide added insulation to hotel buildings, potentially reducing energy costs associated with heating and cooling.

Price Overview

The cost of incorporating polyurethane into hotel exterior designs can vary widely depending on several factors, including the complexity of the design, the size of the hotel, and the location of the project. On average, the price for polyurethane exterior panels can range from $5 to $10 per square foot. However, for custom designs or more intricate patterns, prices can go significantly higher.

It's important for hotel owners and developers to consider the long-term benefits of investing in polyurethane exteriors. While the initial costs may be higher than some other materials, the durability, low maintenance, and energy efficiency can lead to cost savings over time.

Conclusion

Polyurethane is an excellent choice for hotel exterior designs due to its durability, versatility, and aesthetic appeal. While the initial investment may be higher compared to other materials, the long-term benefits and unique design possibilities make it a worthwhile option for many hotel projects. Hotel owners and developers should work with experienced contractors to explore the best polyurethane design solutions that meet their specific needs and budget.

Information Gallery

List of detailed descriptions of images in the image gallery.

English

English

Romanian

Romanian