Polyurethane wall frame molding is a type of decorative frame made from polyurethane material, used on walls.

Polyurethane Wall Frame Moulding

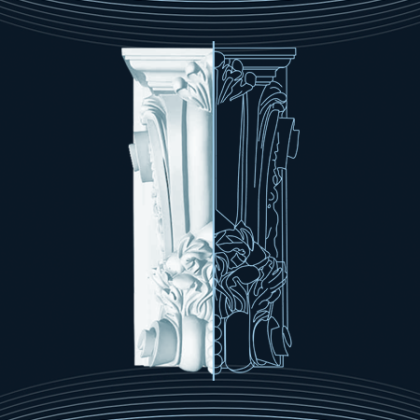

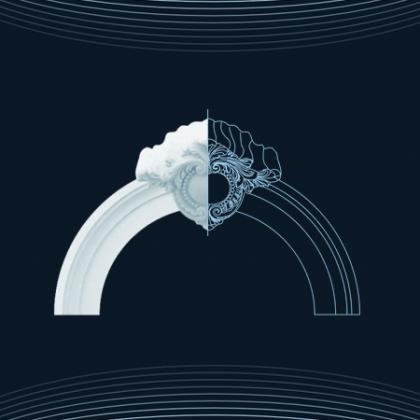

Polyurethane wall frame moulding is a type of decorative trim used to add aesthetic appeal and architectural detail to interior walls. Made from polyurethane, a versatile and durable synthetic polymer, this moulding is designed to mimic the look and feel of traditional wood or plaster mouldings but with several added benefits.

Advantages of Polyurethane Wall Frame Moulding

One of the primary advantages of polyurethane moulding is its resistance to moisture, insects, and decay, making it an ideal choice for both interior and exterior applications. Unlike wood, polyurethane does not warp, crack, or split over time, ensuring a long-lasting and maintenance-free addition to your decor. Furthermore, polyurethane is lightweight, making it easier to handle and install compared to traditional materials.

Design Flexibility

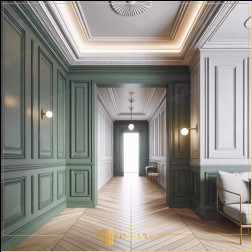

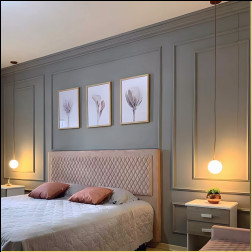

Polyurethane wall frame moulding comes in a wide variety of styles, sizes, and designs, from simple and contemporary to ornate and traditional. This versatility allows homeowners and designers to select the perfect moulding to complement their interior design scheme. Additionally, polyurethane moulding can be painted or stained to match any decor, providing further customization options.

Installation and Application

Installing polyurethane wall frame moulding is a relatively simple process that can be accomplished with standard woodworking tools. The lightweight nature of polyurethane makes it easy to cut, shape, and adhere to walls using construction adhesive and minimal fasteners. This ease of installation makes it an excellent project for DIY enthusiasts looking to enhance their home's aesthetic appeal without the need for professional help.

Environmental Impact

While polyurethane offers many benefits, it is important to consider its environmental impact. Polyurethane is a petroleum-based product, and its production involves chemicals that can be harmful if not managed properly. However, its durability and longevity mean that it does not need to be replaced as frequently as other materials, potentially reducing waste over time.

Conclusion

Polyurethane wall frame moulding is a durable, versatile, and aesthetically pleasing option for enhancing the architectural details of your home. Its resistance to moisture and decay, coupled with its design flexibility and ease of installation, make it a popular choice among homeowners and designers alike. When selecting polyurethane moulding, it is essential to weigh its environmental impact and consider sustainable practices to mitigate any negative effects.

The history of wall frame molding, specifically polyurethane wall frame molding, involves its use as a decorative element in buildings.

The Historical Significance of Wall Frame Moulding, Especially Polyurethane Variants

Wall frame moulding, an architectural element used for centuries, has played a significant role in interior design and the ornamental detailing of spaces. Traditionally crafted from wood, plaster, or stone, mouldings have been used to frame pictures, delineate spaces, and add aesthetic value to interiors. However, the evolution of materials has seen the rise of polyurethane wall frame mouldings, offering durability, versatility, and ease of installation.

Historical Background

The use of mouldings for decorative purposes dates back to ancient civilizations, including the Egyptians and Greeks, who adorned their structures with intricate carvings and embellishments. The Renaissance period marked a significant evolution in the use of mouldings, with artisans and architects experimenting with various materials and designs to add elegance and style to buildings and interiors.

The Rise of Polyurethane Mouldings

In the 20th century, the development of synthetic materials like polyurethane revolutionized the production of wall frame mouldings. Polyurethane, a versatile and lightweight material, made it possible to replicate the intricate designs of traditional mouldings at a lower cost and with improved durability. This innovation not only made decorative mouldings more accessible but also expanded their use beyond the elite to a wider audience.

Advantages of Polyurethane Wall Frame Mouldings

Polyurethane wall frame mouldings offer several advantages over their traditional counterparts. They are resistant to moisture, making them ideal for use in humid or damp environments. Unlike wood, they do not rot, warp, or crack, ensuring longevity and ease of maintenance. Furthermore, their lightweight nature simplifies the installation process, making them a popular choice for both professionals and DIY enthusiasts.

Conclusion

The evolution of wall frame moulding, from its origins in ancient civilizations to the modern use of polyurethane variants, reflects the ongoing search for materials that combine aesthetic appeal with functional benefits. Polyurethane mouldings, in particular, have secured a place in the history of interior design, offering an efficient and cost-effective way to enhance the beauty and elegance of spaces.

Polyurethane wall frame molding is a decorative element for walls. It is known for its durability, light weight, and resistance to moisture and mold. This material can mimic the look of wood or plaster but is easier to install and maintain.

Polyurethane Wall Frame Moulding and Its Properties

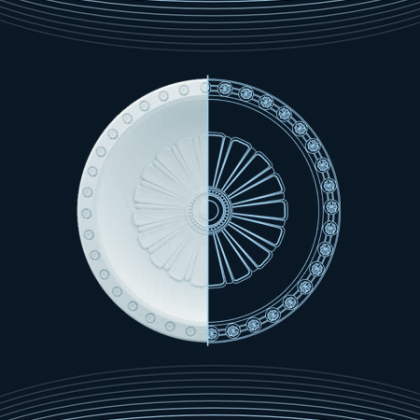

Polyurethane wall frame moulding is a decorative element used in interior design to add elegance and style to walls and ceilings. Made from polyurethane, a type of polymer, it is a versatile and durable material that offers several advantages over traditional moulding materials like wood or plaster.

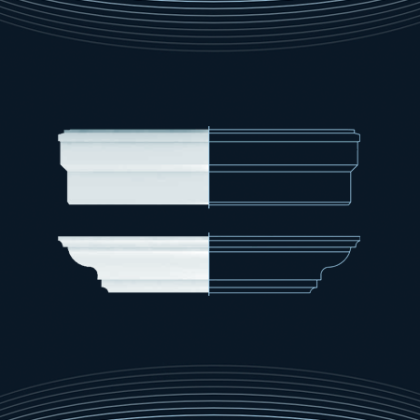

Key Properties of Polyurethane Wall Frame Moulding

- Durability: Polyurethane is resistant to moisture, mold, mildew, and insects, making it an ideal material for both interior and exterior applications. Its durability ensures that it does not crack, warp, or rot over time.

- Lightweight: Despite its durability, polyurethane moulding is lightweight, making it easy to handle and install. This reduces the overall labor cost and time involved in installation.

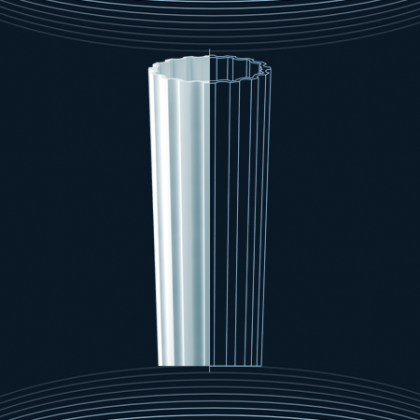

- Flexibility: Polyurethane moulding can be manufactured in a wide range of designs, from simple and sleek to intricate and detailed. It can also be easily cut and adjusted on-site to fit any space perfectly.

- Cost-Effective: Compared to wood or plaster mouldings, polyurethane mouldings are more cost-effective, not only in terms of the initial purchase price but also in terms of maintenance and longevity.

- Easy to Paint: Polyurethane mouldings come ready to paint. They can be painted to match or contrast with the surrounding decor, offering flexibility in design and finishing.

In conclusion, polyurethane wall frame moulding is an excellent choice for anyone looking to enhance the aesthetic appeal of their space. Its unique properties, including durability, lightweight, flexibility, cost-effectiveness, and ease of painting, make it a superior alternative to traditional moulding materials. Whether you are renovating your home or working on a new construction project, polyurethane moulding can provide the finishing touch that makes all the difference.

Are the applications of polyurethane wall frame molding and polyurethane wall frame molding decoration different?

Polyurethane Wall Frame Moulding and Decoration Applications

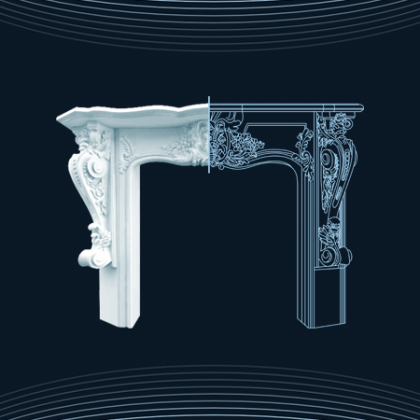

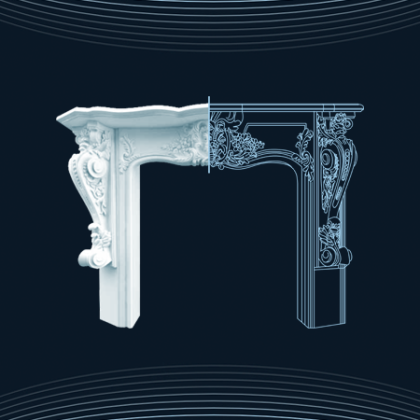

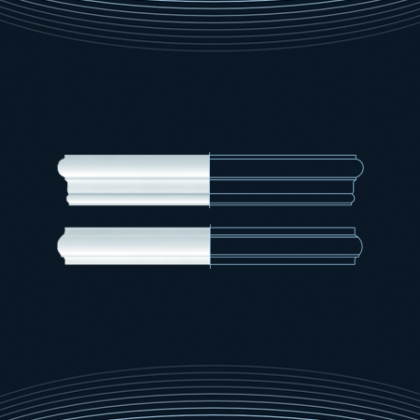

Polyurethane wall frame moulding and decoration are versatile components used in interior design and architecture. They offer a wide range of applications due to their durability, ease of installation, and aesthetic appeal. While these elements share similarities, their usage areas can be distinct, catering to different design needs and preferences.

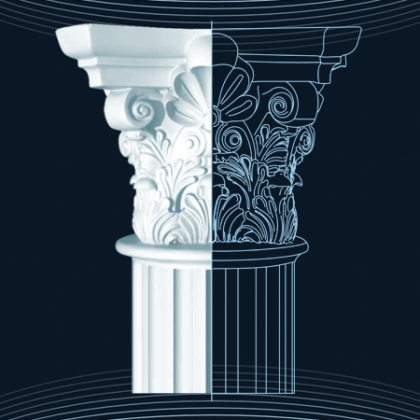

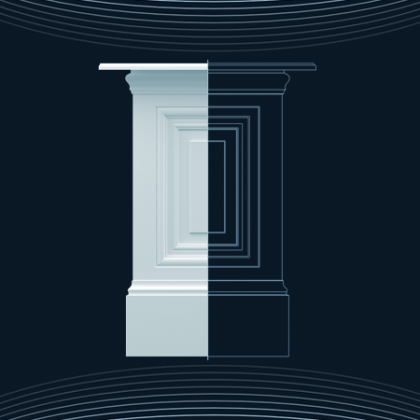

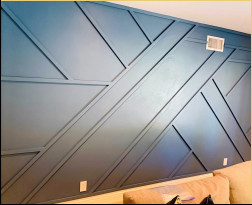

Polyurethane Wall Frame Moulding

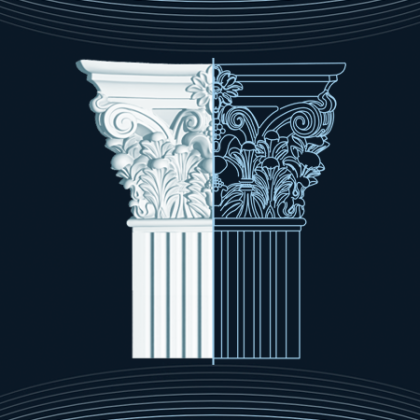

Polyurethane wall frame moulding is primarily used to create frames around doors, windows, and pictures, adding a touch of elegance and structure to any room. These mouldings are lightweight, resistant to moisture and pests, and can easily be painted or finished to match any decor. The primary application of wall frame moulding is to provide a decorative transition between wall surfaces and other architectural elements.

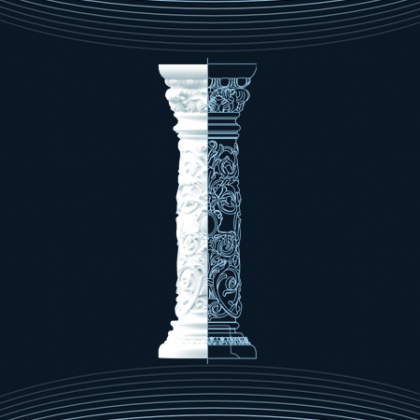

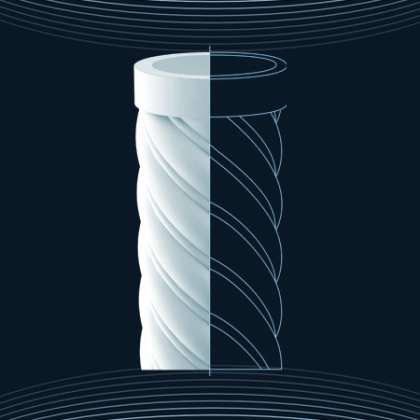

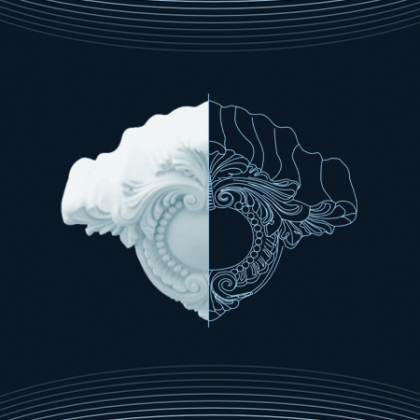

Polyurethane Wall Frame Moulding Decoration

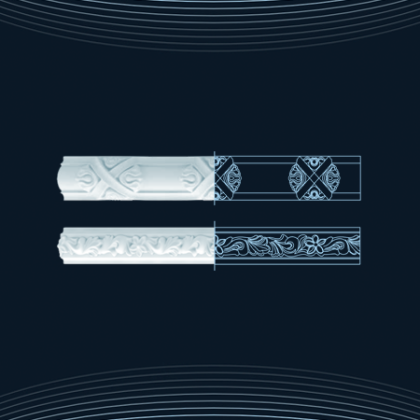

On the other hand, polyurethane wall frame moulding decorations take the aesthetic appeal a step further. These decorative elements can include intricate designs, such as floral patterns, scrolls, or geometric shapes, embedded within or added onto the surface of the moulding. They are often used to enhance the architectural features of a room, adding depth and character to walls, ceilings, and furniture. The primary purpose of these decorations is to embellish and complement the existing decor.

Separate Usage Areas

Although polyurethane wall frame moulding and its decorative counterparts are closely related, their usage areas can be separated based on the specific requirements of a project. Wall frame moulding is often utilized for its functional benefits, providing a clean and finished look around openings or as a method to frame artwork and mirrors. In contrast, decorative moulding is chosen for its ability to enrich and elaborate on the stylistic elements of a space, making it an ideal choice for adding visual interest and a luxurious feel.

Conclusion

In conclusion, while polyurethane wall frame moulding and decoration share common features and benefits, their applications can be distinct. Choosing between them depends on the desired outcome, whether it's to achieve a subtle enhancement with moulding or to make a bold statement with decorative elements. Both options offer the flexibility to transform any space, proving that polyurethane is a valuable material in the world of interior design and architecture.

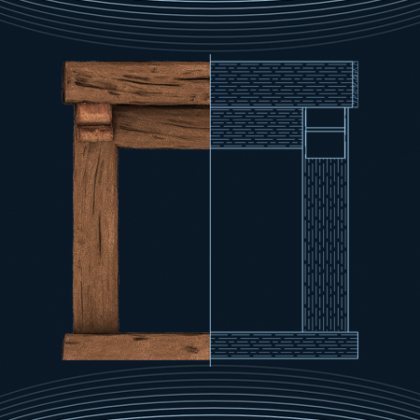

Polyurethane wall frame molding models

Polyurethane Wall Frame Moulding: A Comprehensive Guide

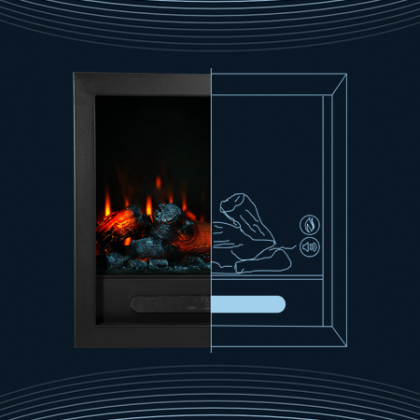

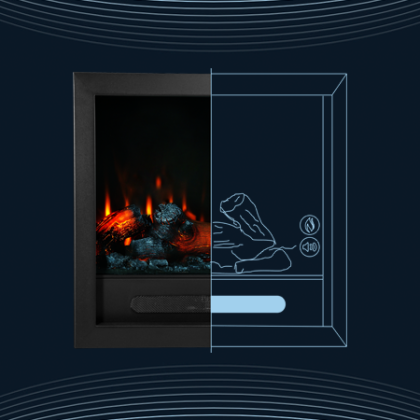

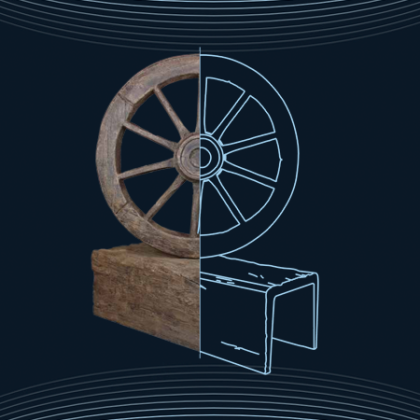

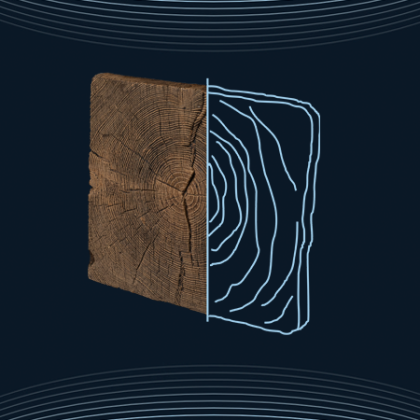

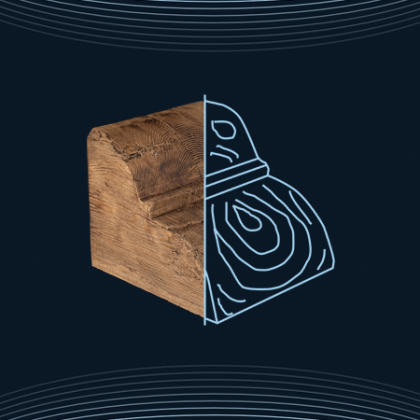

Polyurethane wall frame moulding has become a popular choice for interior designers and homeowners alike due to its durability, ease of installation, and aesthetic appeal. This versatile material can mimic the look of wood, plaster, or stone moulding, providing a cost-effective and maintenance-free alternative. In this article, we'll explore the various models of polyurethane wall frame moulding and their benefits.

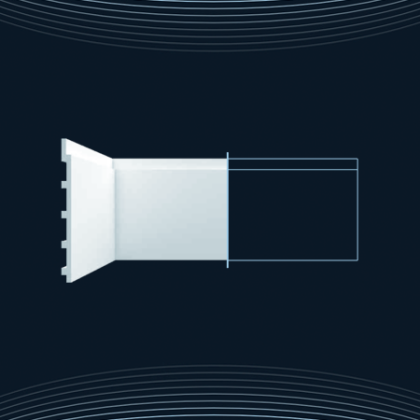

What is Polyurethane Wall Frame Moulding?

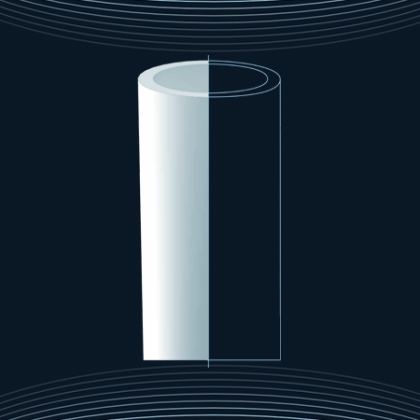

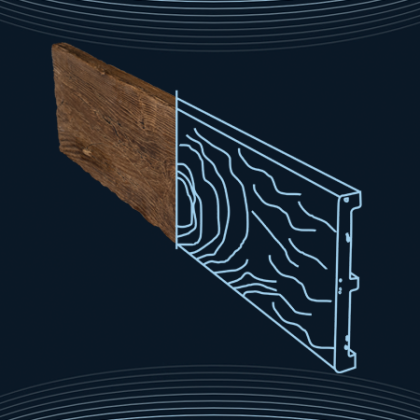

Polyurethane wall frame moulding is a type of decorative moulding made from a dense, durable foam. It is designed to frame walls, doors, windows, and ceilings, adding a touch of elegance and sophistication to any room. Its lightweight nature makes it easy to install, and it can be painted or stained to match any decor.

Benefits of Polyurethane Wall Frame Moulding

- Durability: Polyurethane is resistant to moisture, mold, and mildew, making it an ideal choice for any room, including bathrooms and kitchens.

- Cost-Effective: Compared to traditional wood or plaster mouldings, polyurethane mouldings are more affordable and offer similar aesthetic appeal.

- Easy to Install: Its lightweight nature allows for easy handling and installation, often requiring only adhesive and minimal tools.

- Maintenance-Free: Once installed, polyurethane mouldings do not require the upkeep associated with wood mouldings, such as sanding or repainting.

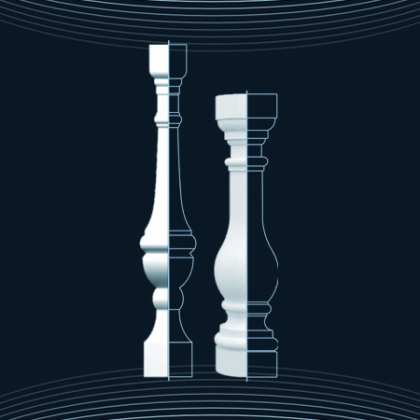

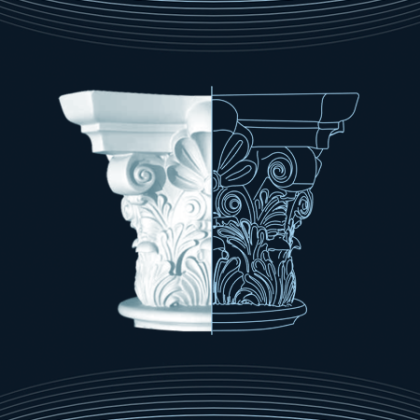

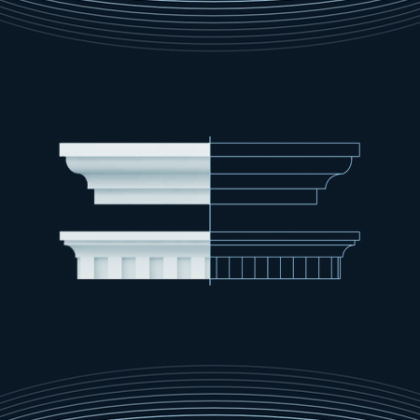

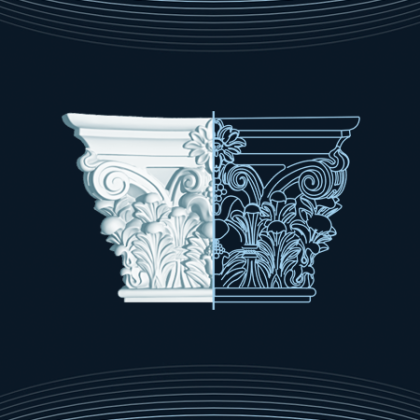

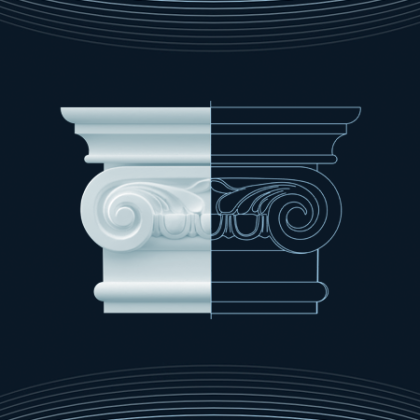

Popular Models of Polyurethane Wall Frame Moulding

There are several models of polyurethane wall frame moulding available, each suited for different design needs and preferences:

- Classic: Features traditional patterns and designs, perfect for adding a timeless elegance to any room.

- Modern: Offers clean lines and minimalist designs, ideal for contemporary spaces.

- Ornate: Characterized by intricate patterns and details, suitable for creating a luxurious and opulent atmosphere.

- Rustic: Mimics the look of natural wood, providing a warm and cozy feel to rustic or country-style interiors.

Conclusion

Polyurethane wall frame moulding is a versatile and practical choice for enhancing the aesthetics of any interior space. With a variety of models available, it's easy to find a style that complements your decor. Whether you're looking for durability, ease of installation, or aesthetic appeal, polyurethane moulding offers a comprehensive solution.

Yes, polyurethane wall frame moulding can be used on exterior walls.

Using Polyurethane Wall Frame Moulding on Exterior Walls

Polyurethane wall frame moulding is a popular choice for interior decoration, known for its durability, ease of installation, and aesthetic appeal. However, homeowners and designers often wonder if this versatile material can be used on exterior walls as well.

Benefits of Polyurethane for Exterior Use

Polyurethane moulding is renowned for its resistance to moisture, mold, and mildew, making it an excellent option for exterior applications. Unlike wood, polyurethane does not rot, warp, or crack, ensuring longevity even in harsh weather conditions. Its lightweight nature also makes it easy to install, reducing labor costs and time.

Considerations for Exterior Application

While polyurethane is inherently resistant to environmental factors, it is crucial to ensure that the specific product used is rated for exterior use. UV resistance is a key factor to consider, as prolonged exposure to sunlight can cause discoloration and degradation of the material. Therefore, selecting a UV-stabilized polyurethane moulding is essential for maintaining its appearance and integrity over time.

Installation and Maintenance

Installing polyurethane moulding on exterior walls is similar to interior applications, requiring adhesive and fasteners suitable for outdoor conditions. Proper sealing and painting with exterior-grade products can further enhance its durability and resistance to the elements. Maintenance is minimal, usually involving routine cleaning to remove dirt and debris.

Conclusion

In conclusion, polyurethane wall frame moulding can be an excellent choice for exterior walls, provided that the material is designed for outdoor use and properly installed. Its durability, ease of maintenance, and aesthetic versatility make it a compelling option for enhancing the exterior appeal of buildings. By considering the specific requirements for exterior application, homeowners and designers can make the most of polyurethane moulding's benefits for their outdoor projects.

Yes, polyurethane wall frame molding can be painted.

Painting Polyurethane Wall Frame Moulding

Polyurethane wall frame moulding has become a popular choice for home decoration and renovation projects due to its durability, ease of installation, and elegant appearance. One common question that arises is whether polyurethane wall frame moulding can be painted. The answer is yes, it can be painted, which allows for a high degree of customization to match any interior design theme.

Preparation for Painting

Before painting polyurethane wall frame moulding, it is essential to prepare the surface properly. Start by cleaning the moulding to remove any dust, dirt, or grease. A mild detergent solution can be used for cleaning, followed by a thorough rinse with clean water. Allow the moulding to dry completely before proceeding.

Next, lightly sand the surface of the moulding with fine-grit sandpaper. This step is crucial as it creates a rough surface for the paint to adhere to. Wipe away any sanding dust with a clean, damp cloth and let the moulding dry.

Choosing the Right Paint

When selecting paint for polyurethane wall frame moulding, acrylic or latex-based paints are highly recommended. These types of paint adhere well to polyurethane and provide a durable finish. It's important to choose a high-quality paint to ensure the best results and longevity of the paint job.

Painting Process

Begin by applying a primer designed for use on plastic materials, as this will help the paint adhere better to the polyurethane surface. Once the primer has dried completely, apply the paint using a high-quality brush or roller. For the best results, apply multiple thin coats of paint rather than a single thick coat. Allow each coat to dry thoroughly before applying the next one.

After the final coat of paint has dried, you may choose to apply a clear sealer to protect the paint and enhance the moulding's overall appearance. This step is optional but can extend the life of the paint job and add a professional touch to your project.

Conclusion

In conclusion, polyurethane wall frame moulding can indeed be painted, allowing for a wide range of design possibilities. With proper preparation, the right choice of paint, and careful application, you can achieve a beautiful and durable finish that complements your home's interior. Whether you're aiming for a subtle enhancement or a bold transformation, painting polyurethane moulding is a project worth considering.

To apply polyurethane wall frame molding, follow these simplified steps: 1. Measure the wall to determine the amount of molding needed. 2. Cut the molding to size, using a saw. 3. Sand the edges of the cuts to smooth them out. 4. Apply construction adhesive on the back of the molding. 5. Press the molding firmly against the wall in the desired location. 6. Use a level to ensure it's straight. 7. Nail the molding into the wall for extra hold, if necessary. 8. Fill any gaps or nail holes with caulk or wood filler. 9. Once dry, sand the filled areas until smooth. 10. Paint or stain the molding as desired.

Applying Polyurethane Wall Frame Moulding

Introduction

Polyurethane wall frame moulding adds elegance and character to any room. It's a durable, lightweight alternative to traditional plaster or wood mouldings. This guide will walk you through the steps to correctly apply polyurethane wall frame moulding, ensuring a professional-looking finish.

Materials Needed

- Polyurethane wall frame moulding

- Adhesive suitable for polyurethane and your wall type

- Caulk and caulk gun

- Measuring tape

- Saw

- Level

- Sandpaper (fine-grit)

- Paint or stain (optional)

- Paintbrush (if painting or staining)

Preparation

Before starting, ensure your walls are clean, dry, and smooth. If you plan to paint or stain the moulding, it's easier to do this before installation. Lightly sand the moulding to remove any imperfections and wipe it down to remove dust.

Installation Steps

- Measure and Cut: Measure the wall to determine the length of moulding needed. Mark the moulding, then cut it at a 45-degree angle for corners, ensuring a tight fit.

- Apply Adhesive: Apply a bead of adhesive along the back of the moulding. For heavier pieces, consider using a few small nails to hold the moulding in place while the adhesive dries.

- Position the Moulding: Carefully place the moulding against the wall, pressing firmly to ensure a good bond. Use a level to make sure it's straight.

- Secure and Seal: If using nails, fill any nail holes with caulk. Then, caulk along the edges where the moulding meets the wall to create a seamless appearance.

- Finishing Touches: Once the adhesive and caulk have dried, touch up any areas with paint or stain as needed.

Conclusion

Installing polyurethane wall frame moulding is a straightforward process that can significantly enhance the look of your space. With the right preparation and careful application, you can achieve a beautiful, professional finish.

Polyurethane wall frame molding is made from a type of plastic that's durable and resistant to moisture. Styrofoam wall frame molding, on the other hand, is made from a lightweight foam material that's easy to cut but less durable and more susceptible to damage.

Differences Between Polyurethane and Styrofoam Wall Frame Moulding

Introduction

When it comes to interior design and home decor, the materials we choose play a pivotal role in the aesthetic and longevity of our spaces. Wall frame moulding, a popular decorative element, can be crafted from various materials, each offering unique characteristics. This article delves into the differences between polyurethane wall frame moulding and styrofoam wall frame moulding, guiding you through their distinct features, benefits, and considerations.

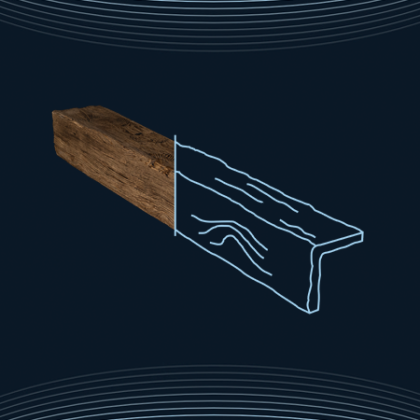

Polyurethane Wall Frame Moulding

Polyurethane wall frame moulding is renowned for its durability, resistance to wear and tear, and ease of maintenance. It is a type of plastic that closely mimics the look and feel of wood but without the susceptibility to rot, mold, or mildew. Polyurethane moulding is also lightweight, making it easier to install than traditional wood moulding. It can be painted or stained to match any decor, offering flexibility in design. Additionally, polyurethane is resistant to warping and cracking, ensuring a long-lasting finish.

Styrofoam Wall Frame Moulding

Styrofoam, or expanded polystyrene (EPS), is another material option for wall frame moulding. It is significantly lighter than polyurethane and even easier to install, often requiring only adhesive. However, Styrofoam moulding is more fragile and susceptible to damage, including dents and scratches. It offers a lower cost alternative but may not provide the same level of durability or aesthetic appeal as polyurethane. Styrofoam moulding is best suited for areas where minimal contact and impact are expected.

Comparison and Considerations

When choosing between polyurethane and Styrofoam wall frame moulding, several factors should be considered. Budget, installation, durability, and the desired final look all play crucial roles in the decision-making process. Polyurethane moulding, while more expensive, offers a durable and high-quality finish that can enhance the value and appeal of your space. On the other hand, Styrofoam moulding presents a cost-effective solution for projects with limited exposure to wear and tear.

In conclusion, both materials have their place in home decor, depending on the project's requirements and constraints. By understanding the differences between polyurethane and Styrofoam wall frame moulding, homeowners and designers can make informed choices that align with their vision and budget.

The difference lies in the materials and processes used for creating wall frame mouldings. Polyurethane wall frame moulding is made from a type of plastic. When comparing it with plaster wall frame moulding, the latter is made from a mixture of water, gypsum, and sometimes fibers, which is then shaped and dried. Polyurethane moulding is lightweight, resistant to moisture and insects, and can mimic the look of wood or plaster but with easier installation and maintenance. Plaster moulding, on the other hand, offers a traditional and classic look but can be more delicate and harder to install.

Differences Between Polyurethane and Plaster Wall Frame Moulding

Introduction

Wall frame moulding adds elegance and character to any room. However, the choice of material can greatly affect the appearance, durability, and ease of installation. This article explores the differences between polyurethane wall frame moulding, polyurethane wall frame moulding with plaster, and traditional plaster wall frame moulding.

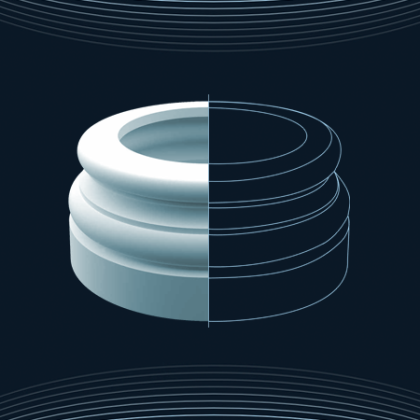

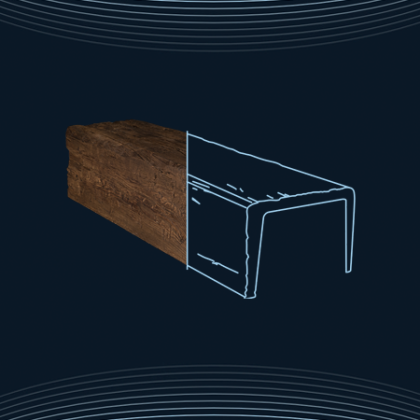

Polyurethane Wall Frame Moulding

Polyurethane wall frame moulding is made from a type of plastic that offers high durability and resistance to moisture. It is lightweight, making it easy to install, and it comes in a variety of designs. Polyurethane is also resistant to warping, rotting, and insect damage, making it a long-lasting option for any environment.

Polyurethane Wall Frame Moulding with Plaster

This type of moulding combines the lightweight and durable properties of polyurethane with a plaster coating. The plaster can be textured or finished in various ways to mimic traditional plaster moulding. This combination offers the classic appearance of plaster with the easy installation and durability of polyurethane.

Plaster Wall Frame Moulding

Traditional plaster wall frame moulding is made by applying wet plaster to a lath (a framework of wire or timber) or directly onto walls. It is highly customizable during the application process, allowing for unique shapes and textures. However, plaster is heavier, more fragile, and more susceptible to moisture damage than polyurethane. Installation and repairs can be more labor-intensive and costly.

Conclusion

Choosing the right material for your wall frame moulding depends on the specific needs of your project. Polyurethane offers ease of installation and durability, while plaster provides a traditional and customizable look. The combination of polyurethane with plaster coating presents a balance of both worlds, offering durability with a classic appearance. Consider your project's requirements in terms of aesthetics, durability, and budget when making your choice.

Polyurethane precast is made from a type of plastic that's flexible and durable, while GRC precast, or Glass Reinforced Concrete, combines cement with glass fibers for strength and lightweight properties.

Difference Between Polyurethane Precast and GRC Precast

Introduction

In the world of construction, precast materials offer significant advantages in terms of quality, speed of construction, and design flexibility. Among these materials, Polyurethane Precast and Glassfiber Reinforced Concrete (GRC) Precast are widely recognized for their unique properties and applications. This article aims to explore the differences between these two precast materials to help architects, builders, and developers make informed decisions.

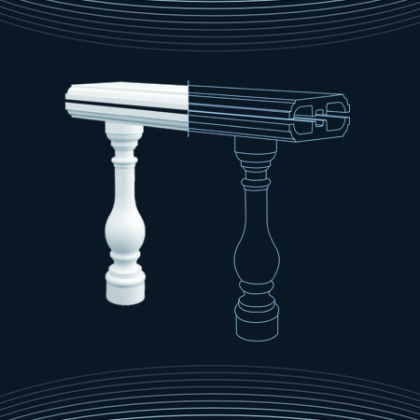

What is Polyurethane Precast?

Polyurethane Precast is a type of building material made from high-density polyurethane foam. It is known for its lightweight, insulation properties, and ease of installation. Polyurethane precast elements can mimic the appearance of wood, stone, or concrete and are commonly used in decorative applications, such as moldings, columns, and facades.

What is GRC Precast?

Glassfiber Reinforced Concrete (GRC) Precast is a composite material consisting of cement, fine aggregate, water, chemical admixtures, and alkali-resistant glass fibers. GRC combines the high strength of glass fibers with the durability of concrete, resulting in a material that is lightweight yet strong, with excellent resistance to weathering and fire. GRC precast is used in a variety of applications, including cladding panels, architectural elements, and landscaping products.

Main Differences

- Material Composition: Polyurethane Precast is primarily made of polyurethane foam, whereas GRC Precast consists of a concrete mix reinforced with glass fibers.

- Weight: Polyurethane precast elements are significantly lighter than GRC precast, making them easier to handle and install.

- Insulation: Polyurethane has superior insulation properties compared to GRC, making it a preferred choice for thermal insulation applications.

- Strength and Durability: GRC precast offers greater strength and durability, especially in terms of resistance to weathering and fire, compared to polyurethane precast.

- Applications: While both materials are used in architectural applications, polyurethane is favored for decorative purposes, and GRC is preferred for structural elements requiring high strength and durability.

Conclusion

Both Polyurethane Precast and GRC Precast have their distinct advantages and ideal applications within the construction industry. The choice between the two depends on the specific requirements of the project, including considerations of weight, strength, durability, insulation, and aesthetic preferences. Understanding the differences between these materials is crucial for making informed decisions that align with the project's goals and sustainability considerations.

Polyurethane wall frame molding prices.

Polyurethane Wall Frame Moulding: An Overview of Prices

Polyurethane wall frame moulding has become a popular choice for home and office decoration, thanks to its durability, ease of installation, and aesthetic appeal. Unlike traditional wood moulding, polyurethane moulding is resistant to moisture, rot, and insects, making it an ideal option for any environment. This article provides an overview of polyurethane wall frame moulding and its pricing to help you make an informed decision for your next renovation project.

Why Choose Polyurethane Wall Frame Moulding?

Polyurethane moulding offers several advantages over its wood and plaster counterparts. It is lightweight, easy to work with, and can be painted or stained to match any decor. Furthermore, its resistance to environmental factors means that it maintains its appearance over time without the need for frequent maintenance.

Factors Influencing Price

The price of polyurethane wall frame moulding can vary based on several factors, including:

- Design Complexity: More intricate designs tend to be more expensive due to the higher manufacturing costs.

- Size: Larger pieces of moulding will cost more due to the increased amount of material used.

- Quality: Higher quality moulding, which offers better durability and finish, will also carry a higher price tag.

- Brand: Prices can vary significantly between different brands.

Price Range

As of the latest market analysis, polyurethane wall frame moulding prices can range from $5 to $30 per linear foot, depending on the factors mentioned above. For specific projects, it's advisable to request quotes from several suppliers to ensure competitive pricing.

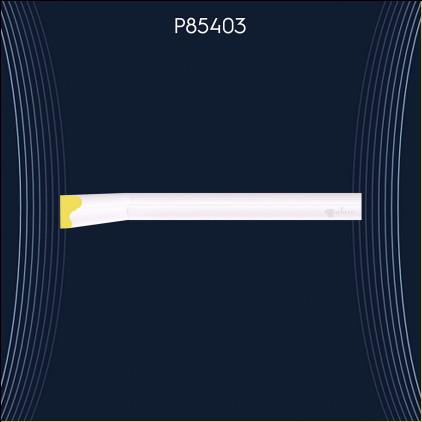

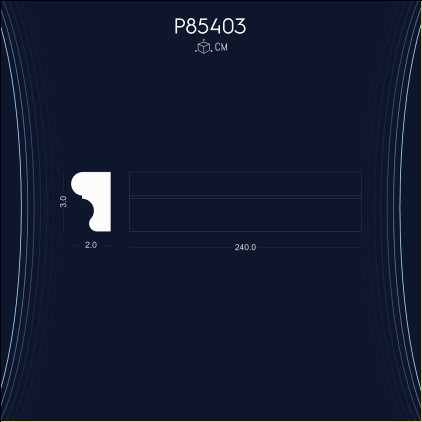

Elegant Polyurethane Flat Frame P85403 - Wall Appliques for Stylish Decor Ideas, Design Models, and Inspirations

19.71 lei 17.74 lei

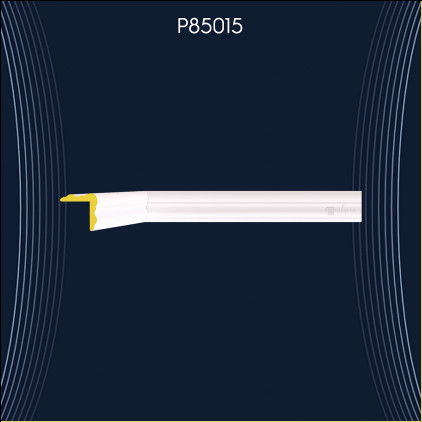

Customizable and Versatile Decoration Models: P85015 Polyurethane Frame Brau Design Ideas for Your Decor

27.27 lei 24.54 lei

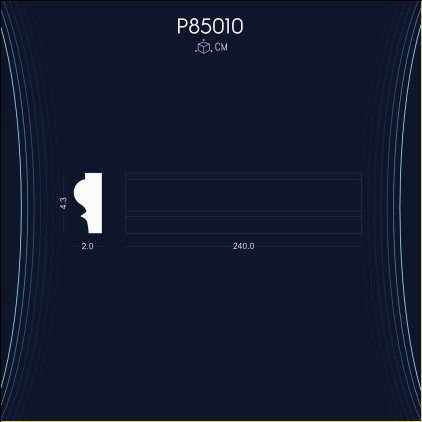

Elegant and Practical Decor with Polyurethane Flat Frames P85010 and Wall Brackets: Design Ideas and Models for Home Decoration

22.69 lei 20.42 lei

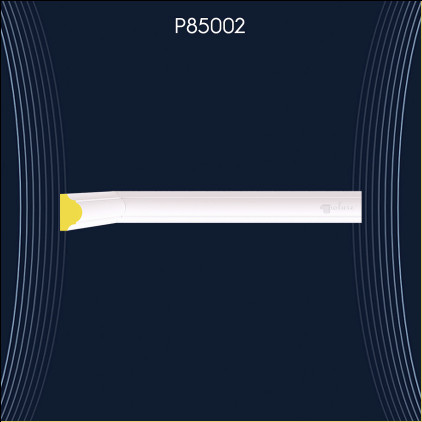

Elegant Polyurethane Frame P85003 Simple Polyurethane Bra: Sophisticated Accent Decor Design Ideas and Examples

17.65 lei 15.89 lei

Information Gallery

List of detailed descriptions of images in the image gallery.

English

English

Romanian

Romanian