Polyurethane window jamb models are types of window frames made from polyurethane, a kind of plastic.

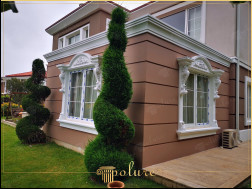

Polyurethane window jamb models represent a significant advancement in the construction and design of window frames. Made from a type of plastic called polyurethane, these jambs offer several advantages over traditional materials like wood or aluminum. Polyurethane is known for its durability, insulation properties, and resistance to moisture, making it an ideal choice for window frames. One of the main benefits of polyurethane window jambs is their durability. Unlike wood, which can rot, or metal, which can corrode, polyurethane is resistant to both water and insects, ensuring a longer lifespan for your windows. Additionally, polyurethane provides excellent insulation, helping to keep your home warmer in the winter and cooler in the summer, which can lead to significant energy savings. Another advantage is the material's flexibility in design. Polyurethane can be molded into a wide variety of shapes and sizes, allowing for custom window designs that can fit any home's aesthetic. Installing polyurethane window jambs is similar to installing traditional window frames, but with the added benefit of being lighter and easier to handle. This can reduce the time and labor costs associated with window installation. Maintenance is also straightforward, as the material does not require painting or staining and can be cleaned with just soap and water. Another consideration for homeowners is the environmental impact of their building materials. Polyurethane is a more eco-friendly option compared to some traditional materials. It is energy-efficient, contributing to lower heating and cooling costs, and it is also recyclable, reducing its impact on landfills. Polyurethane window jamb models offer a modern solution to window design and construction. With their durability, energy efficiency, and design flexibility, they represent a smart choice for homeowners looking to upgrade their windows. As the construction industry continues to evolve, polyurethane window jambs are set to become a more common sight in homes around the world.Polyurethane Window Jamb Models

Advantages of Polyurethane Window Jambs

Installation and Maintenance

Environmental Impact

Conclusion

Window jamb models hold a historical significance as they showcase the evolution of window design and construction techniques over time.

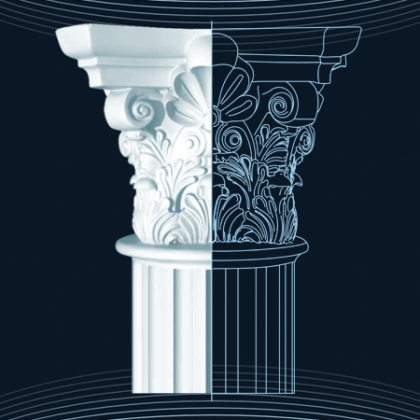

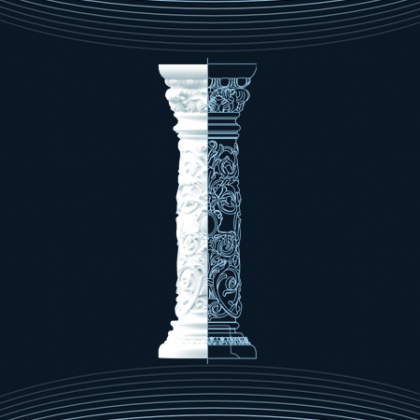

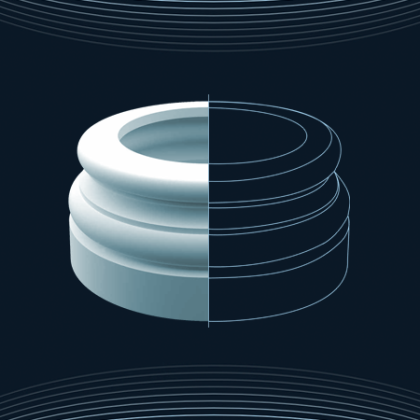

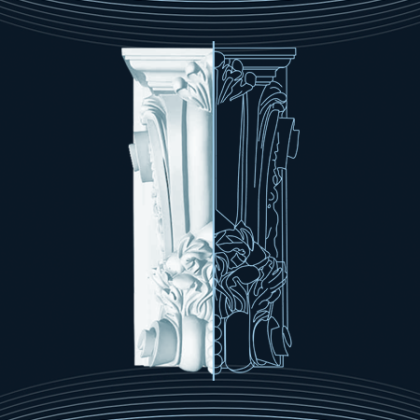

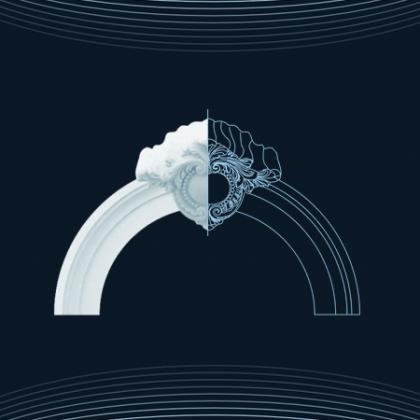

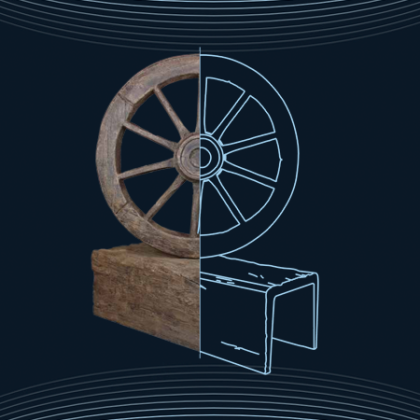

The history of architecture is rich with innovations and stylistic evolutions, among which the development of window jamb models holds a unique place. Window jambs, the vertical sides of a window frame, have been integral to window construction from ancient times to the present, evolving in design and functionality across different architectural periods. The earliest window jamb models can be traced back to ancient civilizations such as the Egyptians and Romans. These early jambs were primarily constructed from stone and wood, serving the dual purpose of structural support and aesthetic enhancement. The Egyptians, known for their monumental architecture, incorporated intricately carved window jambs in their temples and tombs, often depicting religious and cultural motifs. During the medieval period, particularly in Gothic architecture, window jamb models saw significant evolution. The introduction of the pointed arch and the flying buttress allowed for taller buildings with larger windows. Consequently, jambs became more elaborate, often featuring intricate carvings of religious scenes and figures. This period also saw the introduction of stained glass windows, with jambs designed to accommodate and support these colorful additions. The Renaissance era brought a renewed focus on symmetry, proportion, and the use of classical elements in architecture. Window jambs of this period were no exception, with designs that emphasized clean lines and balanced proportions. The use of stone and marble became more prevalent, reflecting the period's appreciation for these materials. As architectural styles continued to evolve, so too did window jamb models. The advent of industrialization introduced new materials such as steel and aluminum, allowing for thinner frames and larger panes of glass. Modern and contemporary architecture has seen a minimalist approach to jambs, focusing on functionality and the maximization of natural light. Throughout history, window jamb models have played a crucial role in the evolution of architectural design. From the ancient stone carvings of Egypt to the sleek, minimalist designs of the modern era, they have adapted to meet the changing needs and aesthetic preferences of society. Today, they continue to be an essential component of window design, embodying the rich history of architectural innovation.The Historical Significance of Window Jamb Models

Ancient Beginnings

Medieval Innovations

Renaissance Refinement

Modern Adaptations

Conclusion

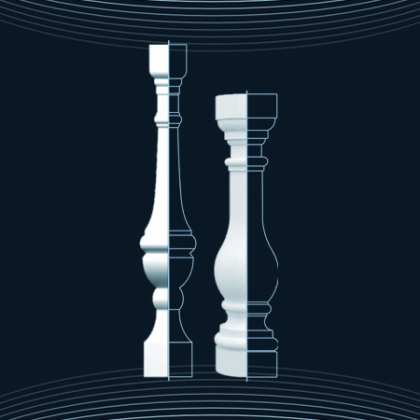

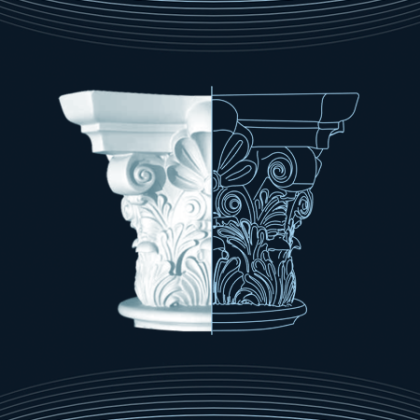

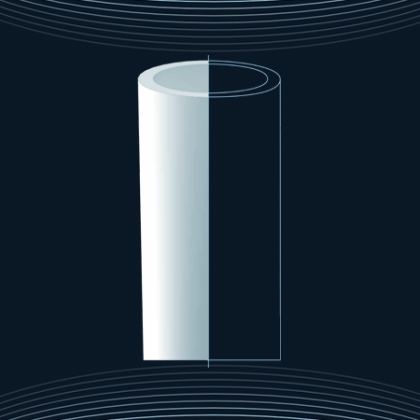

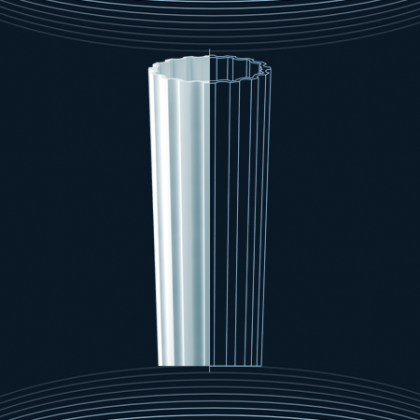

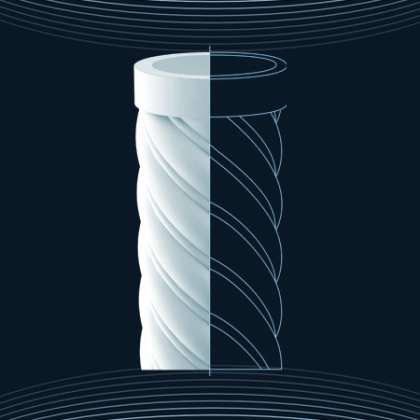

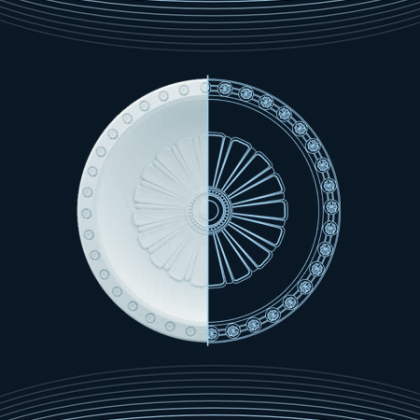

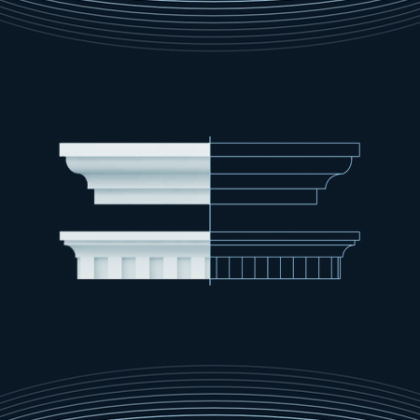

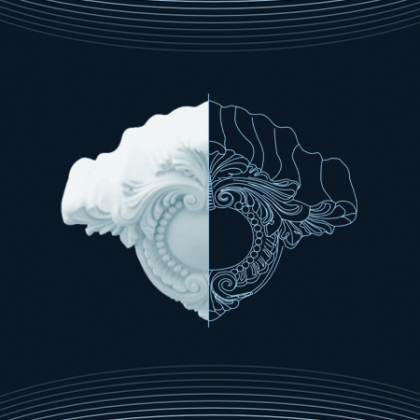

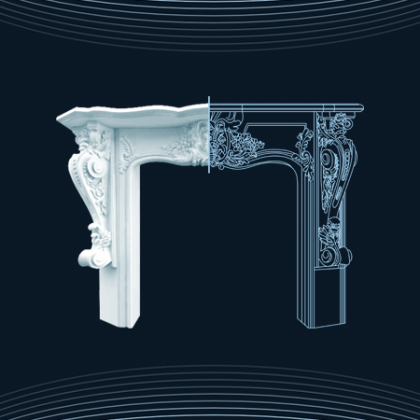

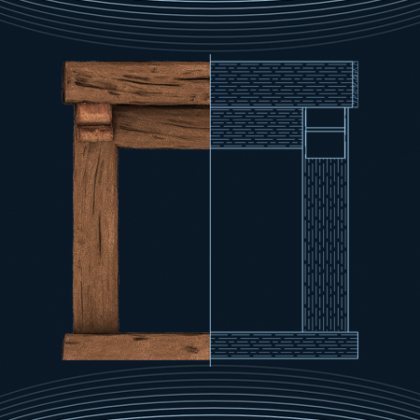

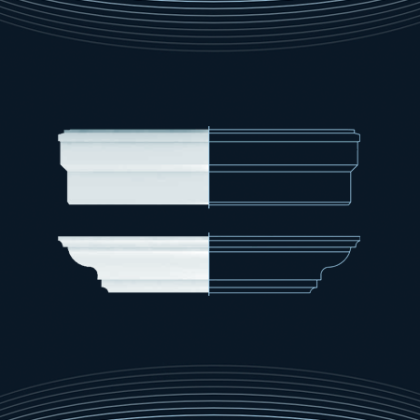

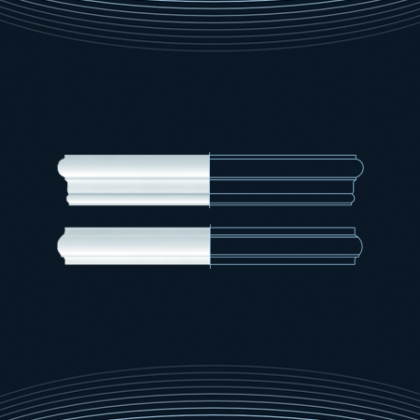

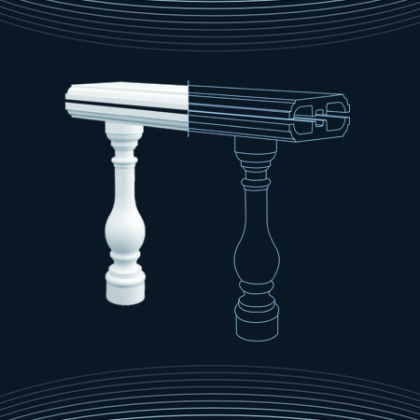

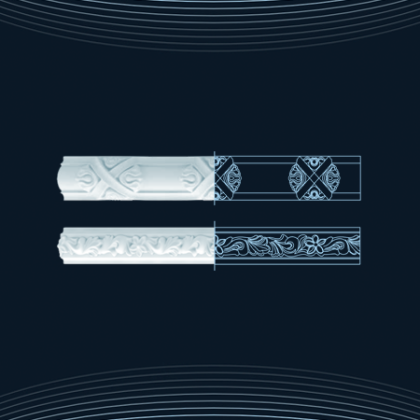

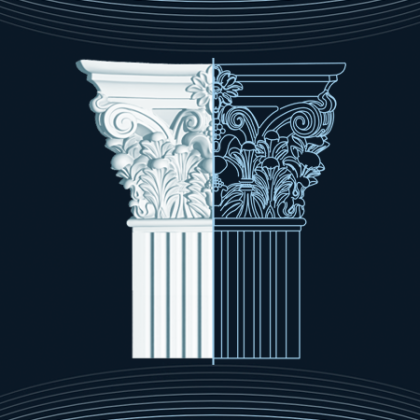

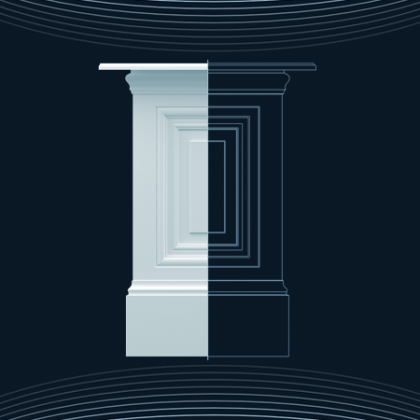

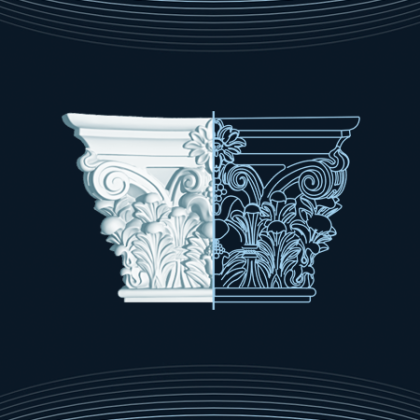

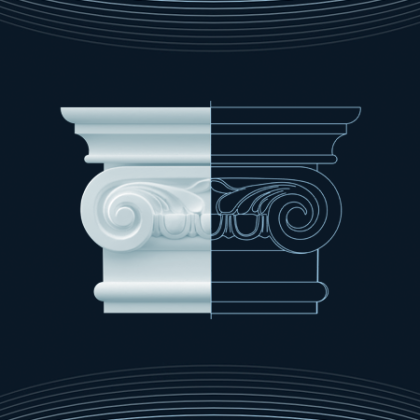

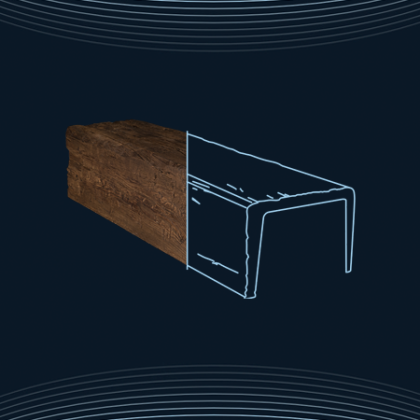

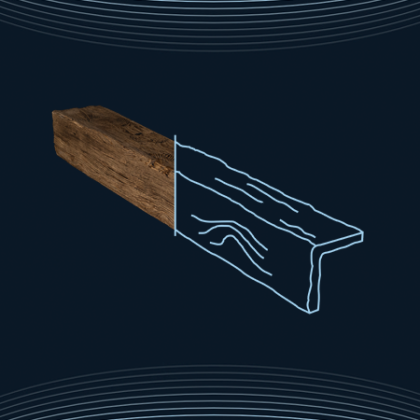

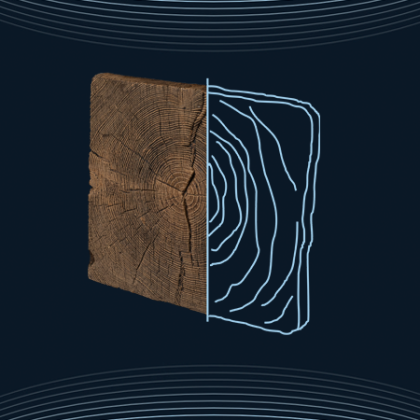

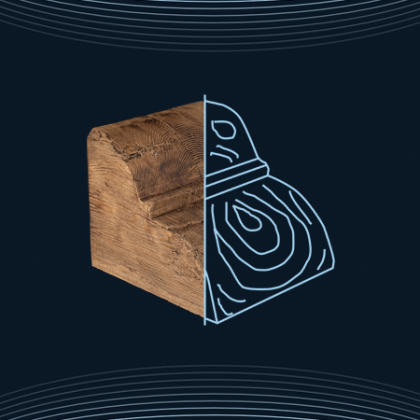

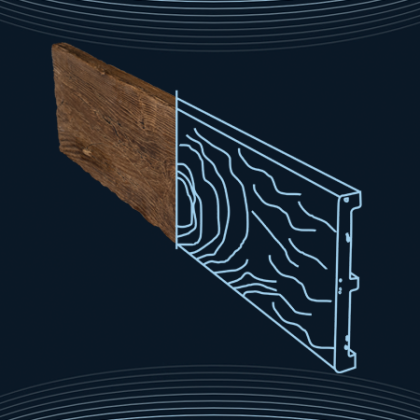

Characteristics of Polyurethane Window Frame Designs

Polyurethane window jambs have become increasingly popular in modern construction due to their exceptional properties and benefits. These models offer a blend of durability, aesthetic appeal, and energy efficiency, making them a preferred choice for both residential and commercial buildings. This article explores the key properties of polyurethane window jamb models that contribute to their growing popularity. Polyurethane is known for its resistance to weathering, rot, and pests. Unlike traditional wood jambs, polyurethane models do not warp, crack, or swell, ensuring a long-lasting performance without the need for frequent replacements or maintenance. This material withstands extreme temperatures and humidity, making it ideal for any climate. One of the most significant advantages of polyurethane window jambs is their energy efficiency. The material provides excellent insulation, reducing heat transfer and helping to maintain consistent indoor temperatures. This can lead to substantial savings on heating and cooling costs, as well as contribute to a more comfortable living environment. Polyurethane window jambs offer a wide range of design options. They can be manufactured in various styles, from traditional to contemporary, and can be painted or stained to match any decor. This versatility allows homeowners and architects to achieve the desired look without compromising on performance. Compared to traditional materials, polyurethane is more environmentally friendly. It is often made from recycled materials and is itself recyclable. Additionally, the energy savings provided by the insulation properties of polyurethane contribute to a reduction in carbon footprint. Polyurethane window jambs are lightweight and easy to install, reducing labor costs and time. They can be easily cut and shaped on site, allowing for a perfect fit even in the most challenging installations. This ease of installation makes them a favorite among contractors and DIY enthusiasts alike. In conclusion, polyurethane window jamb models offer a superior alternative to traditional materials. Their durability, energy efficiency, aesthetic flexibility, environmental benefits, and ease of installation make them an excellent choice for any construction project.Properties of Polyurethane Window Jamb Models

Durability

Energy Efficiency

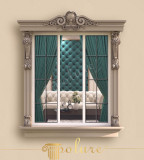

Aesthetic Flexibility

Environmental Impact

Easy Installation

Are the applications of polyurethane window jamb designs for decoration distinct?

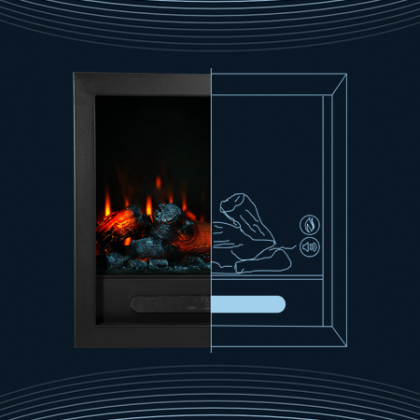

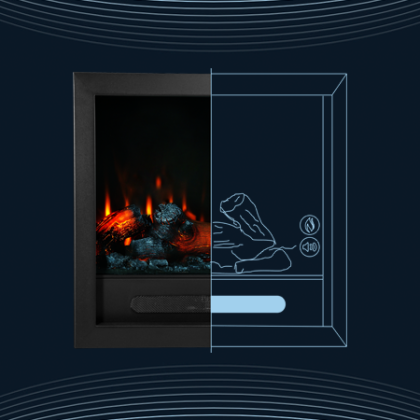

Polyurethane window jambs have become a popular choice in both residential and commercial construction projects due to their versatility, durability, and aesthetic appeal. These architectural elements serve not only a functional purpose but also play a significant role in the decoration of windows. This article explores the various usage areas of polyurethane window jamb models, emphasizing the distinction between their decorative and functional aspects. The primary function of window jambs is to provide a structural frame for windows, ensuring stability and support. Polyurethane, known for its strength and resilience, is an excellent material for this purpose. It can withstand various environmental factors such as moisture, temperature changes, and UV exposure without warping, cracking, or fading. This makes polyurethane window jambs a durable choice for any setting. Beyond their structural benefits, polyurethane window jambs offer extensive decorative possibilities. Available in a wide range of styles, from classic to contemporary, these jambs can complement the architectural design of any building. Manufacturers often incorporate intricate details and finishes that mimic traditional materials like wood or stone, adding a touch of elegance and sophistication to window frames. This versatility allows architects and designers to achieve a desired aesthetic without compromising on quality or durability. In conclusion, polyurethane window jamb models serve both functional and decorative purposes. Their usage areas are indeed separated but also intertwined, as they provide essential support to windows while enhancing the overall appearance of a building. With their durability, versatility, and aesthetic appeal, polyurethane window jambs are a smart choice for anyone looking to combine practicality with style in their construction or renovation projects.Polyurethane Window Jamb Models: Exploring Decorative and Functional Uses

Functional Uses of Polyurethane Window Jambs

Decorative Uses of Polyurethane Window Jambs

Conclusion

Polyurethane window frame designs.

Polyurethane window jambs have become increasingly popular in modern construction and renovation projects. These components, made from a type of plastic called polyurethane, offer a range of benefits over traditional materials like wood or metal. Not only are they resistant to moisture, mold, and mildew, but they also provide excellent insulation properties. Furthermore, polyurethane window jambs are known for their durability and ease of maintenance. The primary advantage of using polyurethane for window jambs is its resistance to environmental factors. Unlike wood, which can warp, rot, or become infested with pests, polyurethane maintains its integrity over time. This makes it an ideal choice for areas exposed to harsh weather conditions or high humidity levels. Additionally, these jambs contribute to energy efficiency by creating a tight seal around windows, minimizing heat loss in the winter and heat gain in the summer. Another significant advantage of polyurethane window jambs is their versatility in design. Manufacturers can easily mold them into various shapes and sizes, allowing for customization to fit any architectural style or preference. Whether you're looking for a sleek, modern look or a more traditional aesthetic, there's likely a polyurethane jamb model that meets your needs. Moreover, these jambs can be painted or finished to match or complement the surrounding decor, offering an additional layer of aesthetic appeal. Installing polyurethane window jambs is relatively straightforward, making them a popular choice among DIY enthusiasts and professional contractors alike. They can be cut, drilled, and fastened using standard woodworking tools, and they don't require any special treatments or coatings. As for maintenance, a simple cleaning with soap and water is usually sufficient to keep them looking new. Unlike wood, there's no need to worry about refinishing or protecting them from the elements, which can save time and money in the long run. In conclusion, polyurethane window jambs offer a practical and stylish solution for both new construction and renovation projects. Their durability, resistance to environmental damage, energy efficiency, and ease of maintenance make them an attractive option for homeowners and builders. With a wide range of designs available, it's easy to find a model that enhances the aesthetic appeal of any home while providing functional benefits. As the demand for sustainable and low-maintenance building materials continues to grow, polyurethane window jambs are set to become an even more popular choice in the years to come.Polyurethane Window Jamb Models

Benefits of Polyurethane Window Jambs

Design and Aesthetic Appeal

Installation and Maintenance

Conclusion

Can polyurethane window frames be used on outside walls?

Polyurethane window jamb models have gained popularity in recent years due to their durability, ease of maintenance, and aesthetic appeal. A common question among homeowners and builders is whether these window jamb models can be used on exterior walls. The answer is a resounding yes, and this article will explore the benefits and considerations of using polyurethane window jamb models for exterior applications. Polyurethane window jambs offer several advantages over traditional materials such as wood or metal. Firstly, polyurethane is highly resistant to weathering, moisture, and insect damage, making it an ideal choice for exterior walls. Unlike wood, which can rot or warp when exposed to moisture, polyurethane maintains its shape and integrity, ensuring a long-lasting, aesthetically pleasing finish. Additionally, polyurethane is a low-maintenance material. It does not require regular painting or sealing, saving homeowners time and money. While polyurethane window jambs are suitable for exterior walls, there are a few considerations to keep in mind. Installation is a critical factor; proper installation ensures that the window jamb fits snugly against the wall, preventing moisture from entering and causing damage. It is also important to choose high-quality polyurethane products that are specifically designed for exterior use, as these will have been treated to resist UV radiation and other environmental factors. In conclusion, polyurethane window jamb models are an excellent choice for exterior walls. Their durability, resistance to environmental factors, and low maintenance requirements make them a superior alternative to traditional materials. However, to ensure the longevity and performance of these window jambs, it is crucial to select high-quality products and ensure proper installation. With these considerations in mind, homeowners and builders can confidently use polyurethane window jambs for their exterior wall applications.Polyurethane Window Jamb Models for Exterior Walls

Benefits of Using Polyurethane Window Jamb Models

Considerations for Exterior Use

Conclusion

Yes, polyurethane window jamb models can be painted.

When it comes to home renovation or construction, selecting the right materials for your windows is crucial. One question that often arises is whether polyurethane window jamb models can be painted. The answer is a resounding yes. Polyurethane is a versatile material that not only offers durability and resistance to moisture but also the ability to be painted to match any decor. Before painting polyurethane window jambs, proper preparation is essential. This involves cleaning the surface thoroughly to remove any dust, dirt, or grease. A light sanding may also be necessary to create a surface that the paint can adhere to more effectively. Not all paints are suitable for polyurethane surfaces. Water-based acrylic paints are recommended as they adhere well to polyurethane and are less likely to cause a reaction. It's important to avoid oil-based paints, which can peel or crack over time when applied to polyurethane. For the best results, applying a primer designed for use on plastic surfaces before painting is advised. This will ensure better paint adhesion and a more uniform color. When painting, use a high-quality brush or roller to avoid leaving brush marks. Apply the paint in thin, even layers, allowing sufficient drying time between coats. In conclusion, polyurethane window jamb models can indeed be painted, provided the right preparation steps are followed, and suitable paints are used. This flexibility allows homeowners and builders to customize the appearance of windows to match any interior or exterior design scheme, making polyurethane an excellent choice for window installations.Can Polyurethane Window Jamb Models Be Painted?

Preparation is Key

Choosing the Right Paint

Application Tips

Conclusion

To apply polyurethane on window jamb models, follow these steps: 1. Clean the surface: Ensure the window jamb is clean, dry, and free of any dust or grease. 2. Sand the surface: Lightly sand the jamb to create a smooth surface for better adhesion. 3. Apply a thin coat: Use a brush to apply a thin, even layer of polyurethane on the jamb. 4. Let it dry: Allow the first coat to dry completely, following the manufacturer's recommended drying time. 5. Sand again: Lightly sand the surface again to ensure a smooth finish. 6. Apply a second coat: For added protection and durability, apply a second thin, even coat of polyurethane. 7. Let it dry: Allow the second coat to dry completely before touching or using the window jamb.

Applying polyurethane to window jamb models is a crucial step in ensuring their durability and aesthetic appeal. This guide will walk you through the process step by step. Applying polyurethane to your window jamb models not only enhances their appearance but also protects them from moisture and wear. By following these steps, you can achieve a professional-looking finish that will last for years.How to Apply Polyurethane on Window Jamb Models

Materials Needed

Preparation

Application

Conclusion

Polyurethane window jamb models are more durable and resistant to wear compared to styrofoam window jamb models, which are lighter and less expensive but not as strong or long-lasting.

When choosing window jamb models, homeowners and builders often consider various materials for their construction projects. Two popular materials are polyurethane and styrofoam. While both materials are used in the production of window jambs, they have distinct differences that can influence a buyer's choice. Polyurethane is known for its exceptional durability and resistance to wear and tear. It can withstand various environmental factors, including moisture, temperature changes, and UV rays, making it an excellent choice for window jambs. On the other hand, styrofoam, while reasonably durable, does not offer the same level of resistance to environmental conditions and may degrade faster over time. When it comes to insulation, styrofoam has a slight edge over polyurethane. Styrofoam's structure makes it a better insulator, helping to keep homes warmer in winter and cooler in summer. However, polyurethane still provides adequate insulation and can be a suitable choice depending on the specific needs of the project. Polyurethane is generally considered to have a higher environmental impact during production compared to styrofoam. The manufacturing process of polyurethane is more energy-intensive and can release more pollutants. However, its durability means it may not need to be replaced as often, potentially reducing its overall environmental footprint. Styrofoam, while less energy-intensive to produce, can contribute to environmental pollution if not disposed of properly, as it is not biodegradable. In terms of cost, styrofoam window jambs are generally less expensive than those made from polyurethane. This makes styrofoam an attractive option for projects with tight budgets. However, considering the durability and longer lifespan of polyurethane, the initial higher investment might offer better value in the long run. Both polyurethane and styrofoam window jamb models have their advantages and disadvantages. The choice between them depends on the specific requirements of the project, including considerations of durability, insulation, environmental impact, and cost. By understanding these differences, homeowners and builders can make informed decisions that best suit their needs.Difference Between Polyurethane and Styrofoam Window Jamb Models

Durability

Insulation

Environmental Impact

Cost

Conclusion

Polyurethane window jamb models are made from a type of plastic, making them durable and resistant to moisture and decay. Plaster window jamb models, on the other hand, are made from a mixture of water, gypsum, and fiber, making them more traditional but susceptible to damage from water and impacts.

When selecting materials for window jambs, homeowners and builders often consider polyurethane and plaster models. Both materials offer unique benefits and drawbacks, making them suitable for different applications. This article explores the key differences between polyurethane and plaster window jamb models to help you make an informed decision. Polyurethane window jambs are known for their durability, resistance to moisture, and ease of installation. Made from a type of plastic, these jambs are lightweight and can be molded into various shapes and styles. They are resistant to rot, mold, and mildew, making them an excellent choice for areas with high humidity levels. Additionally, polyurethane jambs require minimal maintenance and can be easily painted to match any decor. Plaster window jambs offer a traditional and elegant look, often preferred in historic or high-end homes. Plaster is a versatile material that can be shaped and textured to match any architectural style. However, plaster jambs are more susceptible to damage from moisture and require more maintenance than polyurethane. They are also more challenging to install and may require professional help, adding to the overall cost. The main difference between polyurethane and plaster window jambs lies in their material properties and application suitability. Polyurethane jambs are more versatile, durable, and suitable for a wide range of environments, including humid areas. On the other hand, plaster jambs offer a classic appearance that enhances the aesthetic appeal of traditional homes but requires more care and maintenance. In conclusion, the choice between polyurethane and plaster window jamb models depends on your specific needs, preferences, and the environment where they will be installed. Polyurethane is the go-to option for those seeking durability and low maintenance, while plaster is ideal for achieving a sophisticated look in less humid conditions. Carefully consider the pros and cons of each material to select the best window jamb model for your home.Difference Between Polyurethane and Plaster Window Jamb Models

Polyurethane Window Jambs

Plaster Window Jambs

Comparison

Conclusion

Polyurethane precast is made from a type of plastic that's strong and can resist water and wear. GRC precast, which stands for Glass Reinforced Concrete, combines concrete with glass fibers to make it lighter and stronger.

In the world of construction and architectural design, materials play a crucial role in determining the aesthetics, durability, and functionality of buildings and structures. Among the myriad of materials available, polyurethane precast and Glassfibre Reinforced Concrete (GRC) precast are two notable options. While both materials are used for similar applications, including decorative elements and facade panels, they possess distinct characteristics and benefits. This article delves into the differences between polyurethane precast and GRC precast. Polyurethane precast refers to architectural elements that are manufactured using polyurethane, a type of polymer. This material is known for its lightweight, flexibility, and excellent finish. Polyurethane precast products are typically used for decorative elements such as moldings, cornices, and brackets. They are favored for their ability to replicate intricate details and for their ease of installation due to their lightweight nature. GRC precast, or Glassfibre Reinforced Concrete precast, is a composite material made from cement, fine aggregates, water, chemical admixtures, and alkali-resistant glass fibers. This combination results in a material that is both strong and lightweight, with excellent durability and fire resistance. GRC precast is widely used for facade panels, architectural cladding, and outdoor furniture, offering both aesthetic appeal and structural performance. Choosing between polyurethane precast and GRC precast depends on the specific requirements of a project, including considerations of weight, durability, design detail, and environmental impact. Both materials offer unique advantages, making them valuable in different contexts within the construction and architectural fields. Understanding their differences is key to making informed decisions that align with project goals and sustainability considerations.Difference Between Polyurethane Precast and GRC Precast

Introduction

What is Polyurethane Precast?

What is GRC Precast?

Key Differences

Conclusion

Prices for polyurethane window jamb models.

When it comes to home renovation or construction, the choice of materials can significantly affect both the appearance and functionality of your home. Polyurethane window jambs have become increasingly popular due to their durability, ease of maintenance, and aesthetic appeal. This article aims to guide you through the different models of polyurethane window jambs and their respective prices, helping you make an informed decision for your home. Polyurethane window jambs offer several advantages over traditional materials like wood or PVC. They are highly resistant to moisture and will not warp, rot, or succumb to pests. Their insulation properties are superior, making them an excellent choice for energy efficiency. Additionally, they come in a variety of designs and finishes, allowing for greater customization to fit your home's aesthetic. The price of polyurethane window jambs can vary depending on the model, size, and design complexity. Below are some popular models and their average price ranges: Choosing the right polyurethane window jamb for your home involves considering both aesthetic preferences and practical benefits. While the initial cost might be higher than traditional materials, the long-term savings in maintenance and energy efficiency can make it a worthwhile investment. Be sure to consult with a professional to find the best option that suits your home's needs and your budget.Polyurethane Window Jamb Models and Prices

Benefits of Polyurethane Window Jambs

Model Varieties and Pricing

Conclusion

Information Gallery

List of detailed descriptions of images in the image gallery.

English

English

Romanian

Romanian