Polyurethane is a type of plastic.

Polyurethane is a versatile type of plastic that is used in a wide range of applications, from foam mattresses and insulation to paints, adhesives, and even car parts. This material is known for its exceptional durability, flexibility, and resistance to abrasion, making it a popular choice in various industries. Polyurethane is created by reacting a polyol with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. One of the key features of polyurethane is its ability to be tailored to meet specific needs. By adjusting the types of isocyanates, polyols, and additives used, manufacturers can produce polyurethanes with a wide range of properties, including varying levels of rigidity, elasticity, and density. This versatility has led to the widespread use of polyurethane in products such as flexible foam seating, rigid foam insulation panels, elastomeric wheels and tires, and hard plastic parts. Moreover, polyurethane is known for its resistance to chemicals, oil, and UV light, which makes it suitable for outdoor applications. Its ability to form strong bonds with a variety of materials, including metals, plastics, and wood, also contributes to its popularity in adhesives and coatings. Despite its many benefits, polyurethane production and disposal pose environmental and health challenges, primarily due to the toxicity of isocyanates and other chemicals involved in its manufacture. In conclusion, polyurethane is a highly adaptable material that plays a crucial role in modern manufacturing and product development. Its wide range of applications and the ability to customize its properties make it invaluable in numerous fields. However, it is essential to handle polyurethane materials carefully and consider their environmental impact.Polyurethane: An Overview

What is the historical significance of 's?

The apostrophe has a unique place in the annals of history, serving as a punctuation mark that denotes possession or the omission of letters. Its origins can be traced back to the Ancient Greeks, who used it to signify elision in their writing. However, the modern usage of the apostrophe to indicate possession did not become common until the 16th century. Throughout history, the apostrophe has been a subject of debate among grammarians and writers. In the 17th and 18th centuries, its use was highly inconsistent, leading to confusion and varied practices. It was during this time that the rules surrounding the apostrophe began to solidify, thanks in part to the efforts of grammarians who sought to standardize English spelling and punctuation. In contemporary times, the apostrophe continues to hold significance in the English language, though its usage has evolved. The advent of digital communication and informal writing has seen a shift in how apostrophes are perceived and used, leading to common errors and the occasional call for its abolition. Despite this, the apostrophe remains an integral part of English grammar, symbolizing the language's history and its constant state of flux. The apostrophe's journey from ancient Greece to the present day highlights its enduring relevance and the complexities of language evolution. As English continues to change, the apostrophe serves as a reminder of the linguistic intricacies that define human communication.The Place of the 's in History

Polyurethane is a versatile material known for its durability, flexibility, and resistance to abrasion, chemicals, and water. It can be soft and elastic or hard and rigid, making it suitable for a wide range of applications, including insulation, cushions, and coatings.

Polyurethane is a versatile material that has integrated itself into various aspects of our daily lives due to its unique properties. This synthetic polymer is created by reacting a polyol with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. The result is a material that can be engineered to exhibit specific characteristics for different applications. Below, we delve into the key properties that make polyurethane an invaluable material in numerous industries. One of the most significant properties of polyurethane is its durability. Polyurethane products are known for their ability to withstand wear and tear, making them ideal for high-use applications. This durability extends to resistance against abrasion, cutting, and tearing, ensuring that polyurethane products maintain their integrity over time. Polyurethane's flexibility is another hallmark of its versatility. It can be manufactured in various degrees of hardness, from soft, flexible foams to rigid forms. This flexibility allows for its use in a wide range of products, from cushions and mattresses to automotive parts and building insulation. Polyurethane exhibits excellent resistance to oils, solvents, fats, greases, and other chemicals. This makes it suitable for use in environments where exposure to such substances is common, protecting against degradation and maintaining its physical properties over time. Another notable property of polyurethane is its thermal insulation capability. Polyurethane foams are effective insulators, helping to maintain temperature stability in buildings, refrigeration units, and thermal wear. This property is crucial for energy conservation and efficiency in various applications. While not inherently waterproof, polyurethane can be formulated to be water-resistant. This makes it useful for outdoor applications and in products that require a degree of moisture protection, such as coatings and sealants. In conclusion, polyurethane's unique blend of durability, flexibility, chemical resistance, thermal insulation, and water resistance makes it a preferred material for a wide range of applications. Its ability to be customized for specific needs further enhances its appeal across various industries, solidifying its role as a key material in modern manufacturing and product development.Polyurethane Properties

Durability

Flexibility

Chemical Resistance

Thermal Insulation

Water Resistance

Conclusion

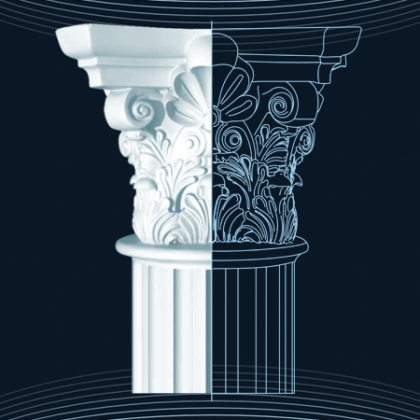

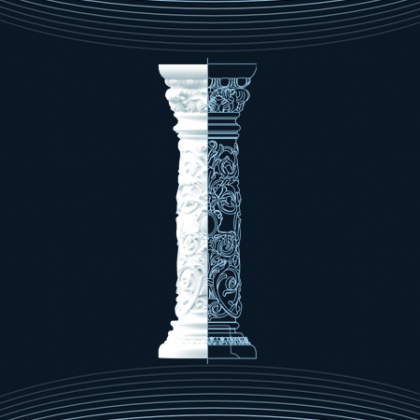

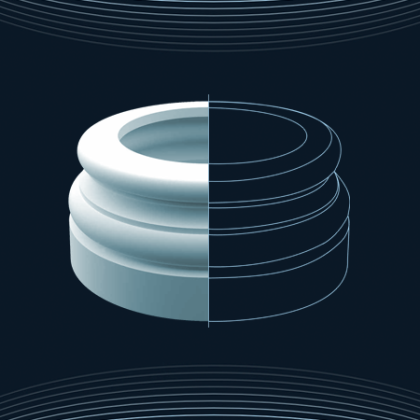

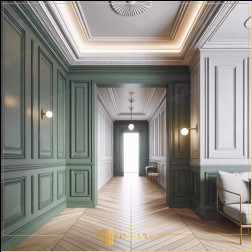

Yes, the applications of polyurethane decoration are distinct.

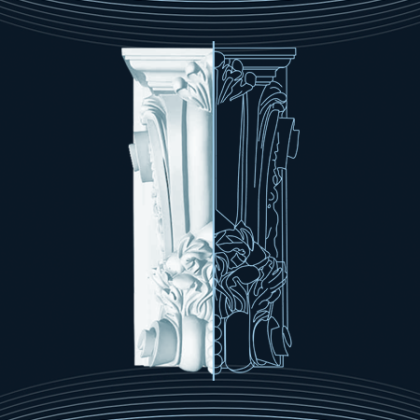

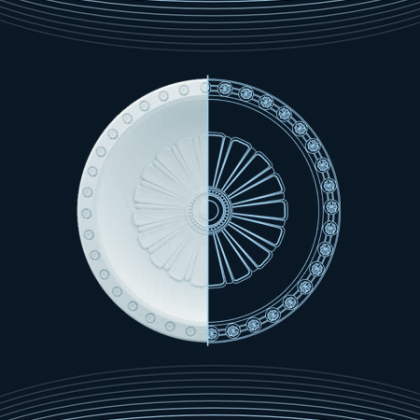

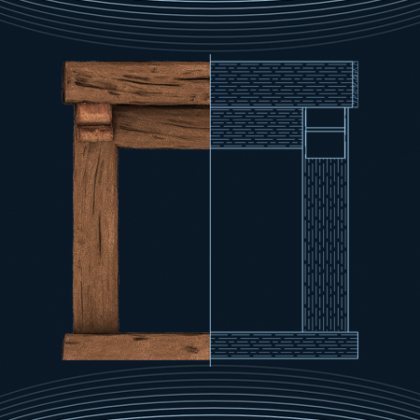

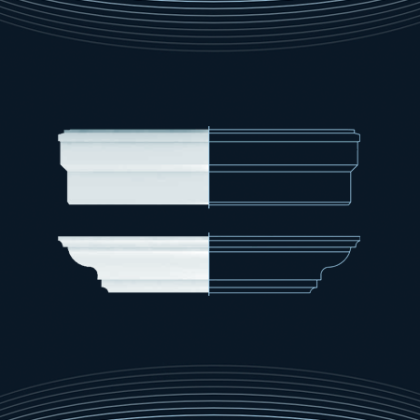

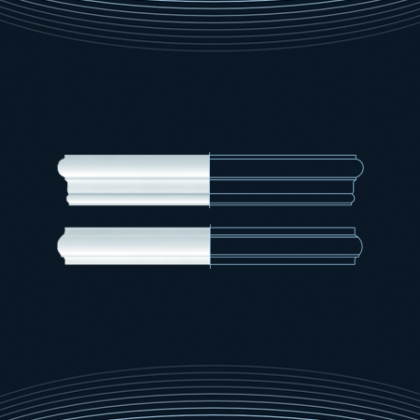

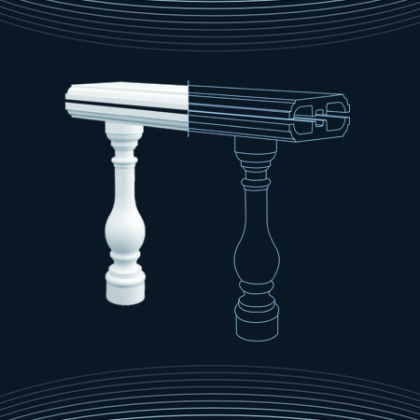

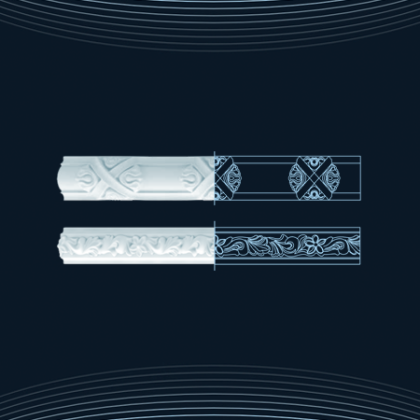

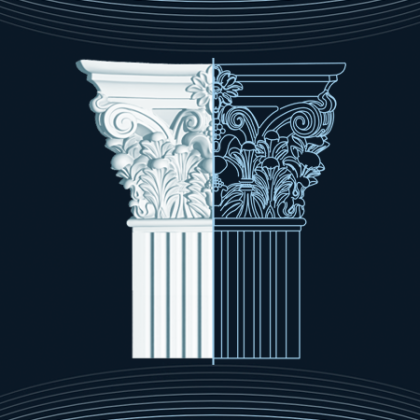

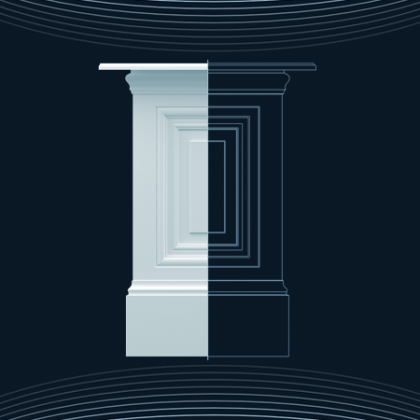

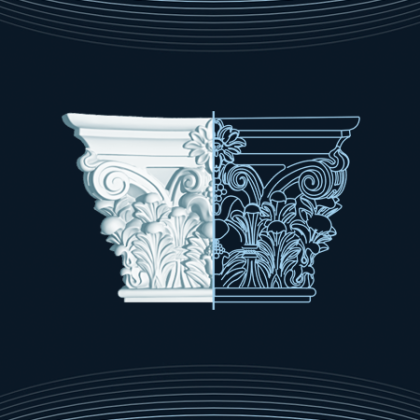

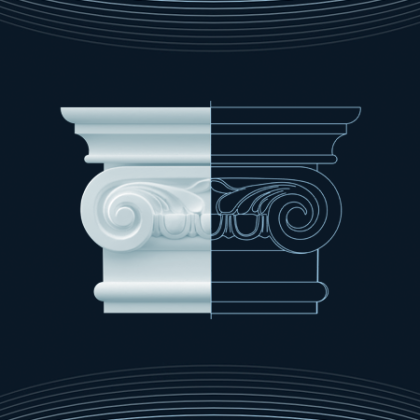

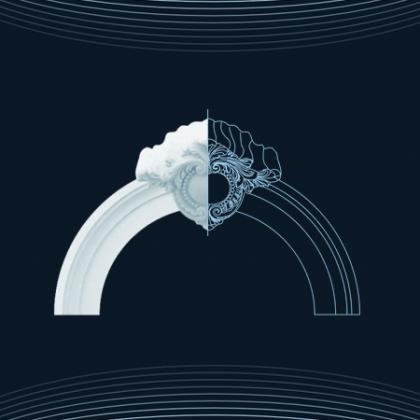

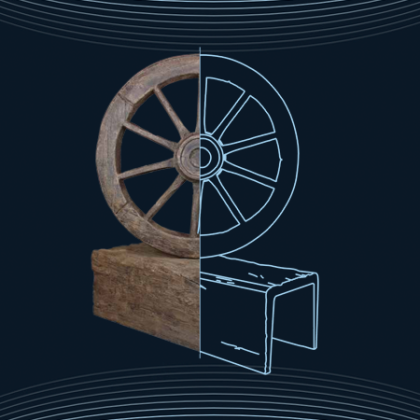

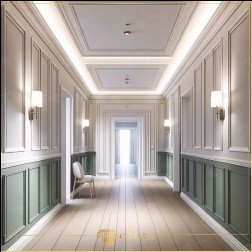

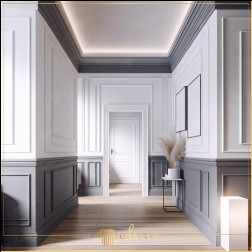

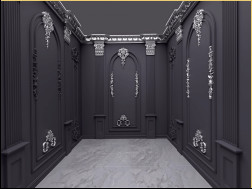

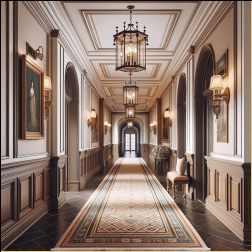

Polyurethane is a versatile material widely used in the construction and decoration industries due to its durability, flexibility, and aesthetic appeal. The usage areas of polyurethane decoration are indeed separated into various categories, each serving distinct purposes and environments. This article explores these categories, highlighting the diversity and adaptability of polyurethane in decoration. In interior decoration, polyurethane is often used for molding, trim, and decorative panels. It provides a lightweight, easy-to-install, and cost-effective alternative to traditional materials like wood or plaster. Polyurethane moldings can be designed to mimic intricate patterns and textures, offering endless possibilities for personalizing spaces. Polyurethane finds extensive use in furniture manufacturing, especially in creating detailed and durable components such as frames, legs, and decorative elements. Its ability to be molded into complex shapes and finishes allows for innovative furniture designs that are both functional and visually appealing. For exterior decoration, polyurethane is valued for its resistance to weather conditions, decay, and pests. It is commonly used for exterior moldings, columns, balustrades, and door and window frames. These applications benefit from polyurethane's strength and longevity, ensuring that the decorative elements remain intact and appealing over time. Themed environments, such as amusement parks, museums, and retail spaces, often utilize polyurethane for creating realistic and durable scenic elements. Polyurethane's versatility in texture and form makes it ideal for crafting detailed props, facades, and landscapes that withstand the elements and heavy use. The separated usage areas of polyurethane decoration underscore its adaptability and efficiency in both interior and exterior applications. From enhancing the aesthetic of living spaces to enduring the rigors of themed environments, polyurethane continues to be a preferred material for decorators and designers seeking reliability and creativity.Polyurethane Decoration Usage Areas

Interior Decoration

Furniture Manufacturing

Exterior Decoration

Themed Environments

Conclusion

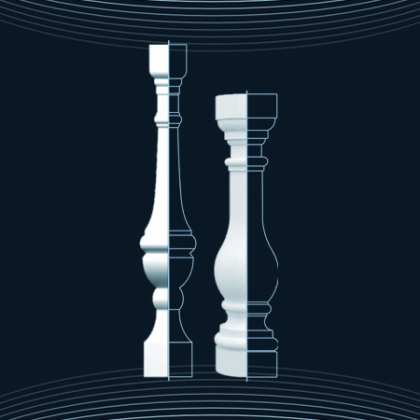

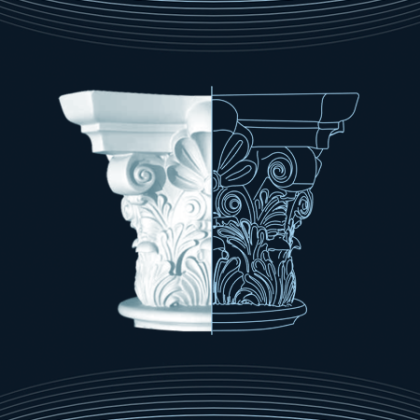

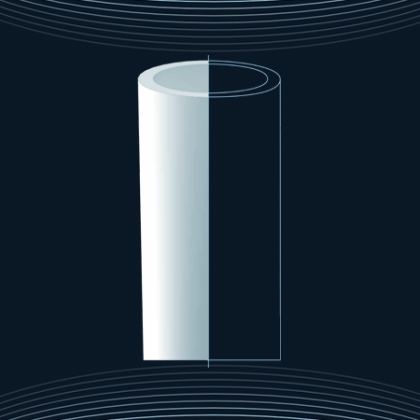

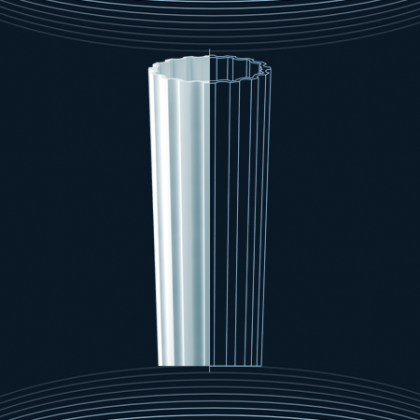

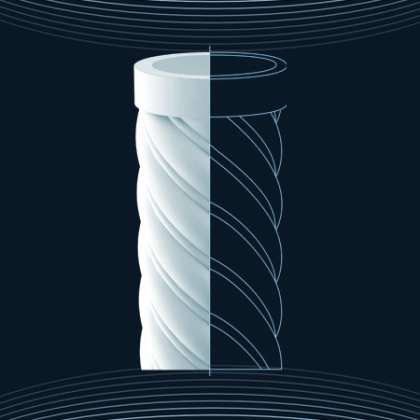

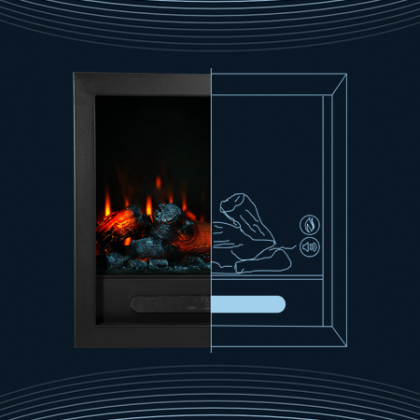

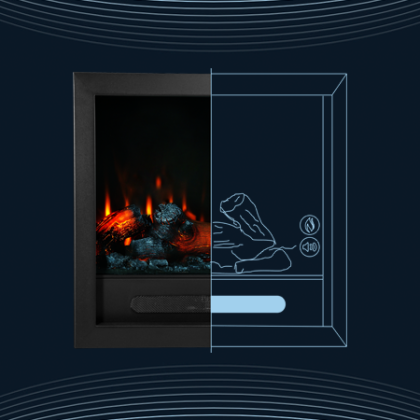

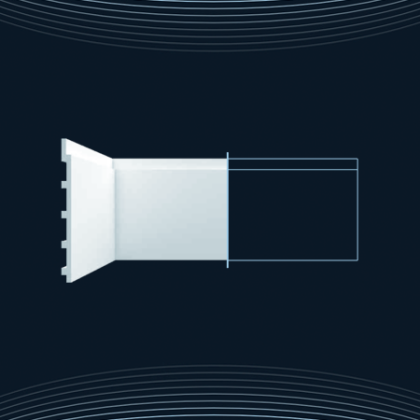

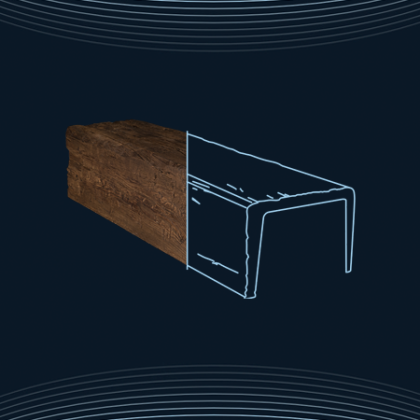

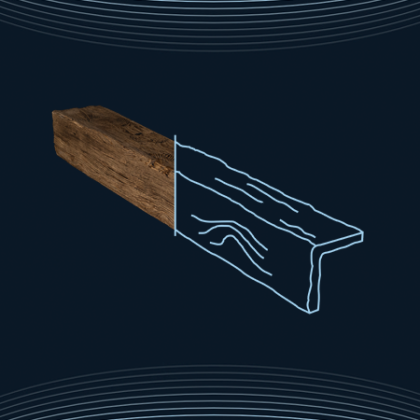

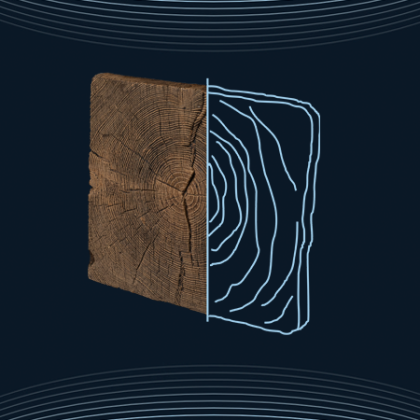

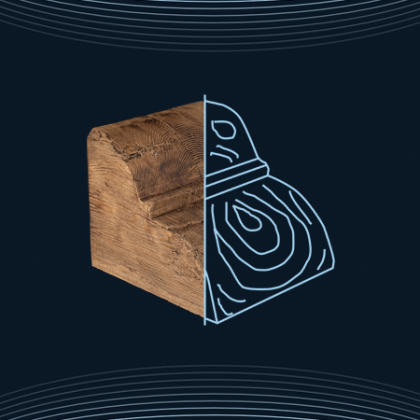

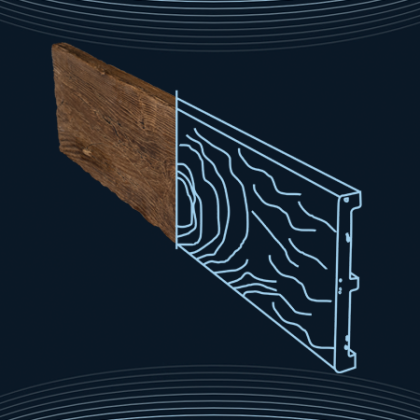

Polyurethane models

Polyurethane, a versatile polymer used in various applications, has become increasingly popular in the modeling industry. Known for its flexibility, durability, and resistance to environmental factors, polyurethane models are now widely used in prototypes, architectural models, automotive parts, and even in the film and entertainment industry for props and special effects. There are primarily two types of polyurethane used in models: rigid and flexible. Rigid polyurethane is often used in creating models that require fine details and high stability, such as architectural models and intricate prototypes. Flexible polyurethane, on the other hand, is chosen for models that need to withstand bending and flexing, like wearable props or functional parts in machinery. The use of polyurethane in models offers several advantages. Firstly, it can be cast into virtually any shape, size, and texture, allowing for a high degree of customization. Secondly, polyurethane models are durable and long-lasting, capable of resisting wear and tear, chemicals, and environmental factors. Additionally, polyurethane can be formulated to mimic a wide range of materials, from soft rubber to hard plastics, making it extremely versatile. Polyurethane models find applications in numerous fields. In the automotive industry, they are used for prototyping new designs and testing parts. Architects and designers use polyurethane models to visualize new buildings and structures. The film and entertainment industry relies on polyurethane for realistic props and special effects that are both durable and lightweight. In conclusion, polyurethane models offer a flexible and durable solution for a wide range of industries. Their versatility and resistance to various factors make them an ideal choice for professionals seeking high-quality, customizable models. As technology advances, the use of polyurethane in modeling is expected to grow, further expanding its applications and possibilities.Polyurethane Models

Types of Polyurethane Models

Advantages of Using Polyurethane

Applications of Polyurethane Models

Conclusion

Can polyurethane be applied to outside walls?

Polyurethane is a versatile material widely used in various applications, from insulation to finishes, due to its durability and resistance to moisture and chemicals. When it comes to exterior walls, the question arises: can polyurethane be effectively used? The answer is yes, but with certain considerations. Polyurethane offers several benefits when applied to exterior walls. It provides excellent insulation, helping to reduce energy costs by keeping heat in during the winter and out during the summer. Its moisture resistance helps protect walls from rain and humidity, preventing mold and mildew growth. Additionally, polyurethane finishes can protect the exterior from UV rays and physical wear, prolonging the life of the wall material beneath. While polyurethane is beneficial for exterior walls, there are important considerations to ensure its effectiveness and durability. Firstly, the type of polyurethane used is crucial. Exterior applications require a product specifically designed for outdoor use, capable of withstanding UV exposure and temperature fluctuations without degrading. Preparation of the surface is also key. The wall must be clean, dry, and free of any loose material or debris to ensure proper adhesion of the polyurethane. Applying a primer may be necessary for some surfaces to enhance this adhesion. Finally, the application method and conditions matter. It is best to apply polyurethane in dry, mild weather conditions to ensure it cures properly. Following the manufacturer's instructions for application and curing times is essential for achieving the best results. In conclusion, polyurethane can be an excellent choice for exterior walls, offering benefits such as insulation, moisture resistance, and protection against wear. However, success with polyurethane on exterior walls depends on choosing the right product, preparing the surface properly, and applying it under suitable conditions. With careful consideration of these factors, polyurethane can significantly enhance the durability and performance of exterior walls.Can Polyurethane Be Used on Exterior Walls?

Benefits of Using Polyurethane on Exterior Walls

Considerations and Best Practices

Conclusion

Yes, polyurethane can be painted.

Many homeowners and DIY enthusiasts often find themselves wondering whether they can paint over polyurethane surfaces or not. The answer is yes, but there are important steps and considerations to ensure the paint adheres properly and the finish is durable. Before painting over polyurethane, the surface must be prepared properly. This involves cleaning the surface thoroughly to remove any grease, dirt, or other contaminants. After cleaning, the surface should be sanded lightly. This roughens up the polyurethane coat, providing a better surface for the paint to adhere to. Not all paints are suitable for use over polyurethane. Water-based paints are generally recommended because they adhere better and are easier to work with than oil-based paints. However, if the existing polyurethane coat is oil-based, an oil-based paint may also be used. It's essential to use a high-quality primer designed for use on polyurethane surfaces before applying the topcoat. When painting over polyurethane, applying thin coats is advisable. Start with a primer designed for slick surfaces to ensure good adhesion. Once the primer is dry, apply the paint in thin, even coats, allowing each coat to dry thoroughly before applying the next. This will help avoid drips and ensure a smooth finish. While painting over polyurethane is certainly possible, it requires proper preparation, the right materials, and a bit of patience. By following these guidelines, you can give your polyurethane-coated surfaces a fresh, new look.Can Polyurethane Be Painted?

Preparation is Key

Choosing the Right Paint

Application Tips

Conclusion

To apply polyurethane, follow these steps: 1. Prepare the surface by sanding it smooth. 2. Clean off any dust with a tack cloth or a damp rag. 3. Apply a thin coat of polyurethane using a brush or a foam applicator. 4. Let it dry as per the instructions on the can. 5. Sand lightly with fine-grit sandpaper. 6. Clean off the dust. 7. Apply a second coat. 8. Allow it to dry completely.

Applying polyurethane to wood surfaces is an excellent way to protect and enhance the wood's natural beauty. Here is a step-by-step guide on how to properly apply polyurethane, ensuring a smooth, durable finish. With patience and attention to detail, applying polyurethane can protect your wood surfaces and enhance their appearance for years to come.How to Apply Polyurethane

Preparation

Application

Final Touches

Polyurethane is a versatile plastic material used in a wide range of products, from foam insulation to furniture and car parts. It is durable, flexible, and can be made into either soft or rigid forms. Styrofoam, on the other hand, is a brand name for a type of polystyrene foam specifically used for insulation and craft materials. It is lightweight, has excellent insulation properties, but is less durable and more prone to breaking than polyurethane.

In the realm of materials used for insulation, packaging, and various other applications, polyurethane and Styrofoam are two commonly encountered names. Though both materials are used in similar contexts, they have distinct properties and are made from different chemical compositions. Understanding the differences between these two materials can help in choosing the right one for specific needs. Polyurethane is a versatile polymer that can be rigid or flexible, making it suitable for a wide range of applications, from insulation and mattresses to automotive parts and footwear. It is formed by reacting a polyol with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. Polyurethane can be found in various forms, including foams, elastomers, and solids. Styrofoam, on the other hand, is a trademarked brand of closed-cell extruded polystyrene foam (XPS) owned by the Dow Chemical Company. Styrofoam is widely recognized for its excellent insulation properties, light weight, and buoyancy. It is commonly used in building insulation, as well as in disposable food containers and packaging materials. Despite its name being widely used to refer to various types of expanded polystyrene (EPS) foam, true Styrofoam is a specific type of XPS. While both polyurethane and Styrofoam serve important roles in various industries, their differences in composition, properties, and applications make them suitable for specific purposes. Understanding these differences is crucial for making informed decisions regarding their use in any project or application.Difference Between Polyurethane and Styrofoam

Introduction

What is Polyurethane?

What is Styrofoam?

Key Differences

Conclusion

Polyurethane is a type of durable plastic, while plaster is a mixture used for coating, decorating, and molding walls and ceilings.

When it comes to choosing materials for molding, casting, and interior decoration, polyurethane and plaster are two of the most popular options. While both materials are used in similar applications, they possess distinct characteristics that set them apart. Understanding the differences between polyurethane and plaster is crucial for making the right choice for your project. Polyurethane is a type of polymer that is flexible, durable, and resistant to both water and impact. It can mimic the appearance of wood, stone, or metal, making it a versatile choice for decorative purposes. On the other hand, plaster is a mixture of water, gypsum, or cement, which hardens over time. It is known for its smooth finish and is commonly used for creating detailed architectural elements and coatings. Polyurethane is widely used in the production of decorative moldings, furniture, panels, and doors due to its durability and resistance to moisture and wear. It is also favored for outdoor applications. Plaster, meanwhile, is preferred for indoor applications, such as creating decorative cornices, ceiling roses, and in restoration projects for its ability to produce a seamless and classic finish. Working with polyurethane is generally easier and less messy than plaster. Polyurethane products are lightweight, can be easily cut, and attached with adhesives or nails. Plaster requires mixing and a skilled hand to apply and shape it, making the installation process more labor-intensive and time-consuming. Polyurethane, being a synthetic material, can release volatile organic compounds (VOCs) into the environment during its production and disposal. However, there are eco-friendly polyurethane options available that minimize these effects. Plaster, made from natural materials, is considered more environmentally friendly and safer for indoor air quality. However, the dust created during its application can pose respiratory hazards if not properly managed. The cost of polyurethane and plaster varies depending on the quality and the complexity of the products. Generally, polyurethane tends to be more expensive than plaster due to its durability and resistance properties. However, the overall cost also depends on the scale of the project and the labor involved in installation. In conclusion, the choice between polyurethane and plaster depends on the specific requirements of your project, including the desired aesthetic, application environment, budget, and installation considerations. By understanding the unique properties and applications of each material, you can make an informed decision that meets your needs.Difference Between Polyurethane and Plaster

Composition and Properties

Applications

Installation and Workability

Environmental Impact and Health Considerations

Cost

Polyurethane precast and GRC (Glass Reinforced Concrete) precast are both types of materials used in construction, but they differ in composition and properties. Polyurethane precast is made from a type of plastic that is durable and resistant to weather, making it lightweight and easy to shape. GRC precast, on the other hand, is a mixture of cement and glass fibers, offering strength and flexibility, and is more suited for detailed architectural elements.

In the construction industry, precast elements are widely used for their efficiency and reliability. Among the various materials used for precast elements, polyurethane and Glassfibre Reinforced Concrete (GRC) stand out for their unique properties and applications. Understanding the differences between polyurethane precast and GRC precast is essential for architects, engineers, and builders to make informed decisions based on their project requirements. Polyurethane precast refers to the use of high-density polyurethane foam in creating architectural and decorative elements. This material is known for its lightweight, durability, and excellent thermal insulation properties. Polyurethane precast elements can mimic the appearance of more traditional materials like wood, stone, or concrete, while offering easier installation and maintenance. GRC precast, on the other hand, involves the use of high-strength glass fibre embedded in a cementitious matrix. This combination results in a material that is both lightweight and extremely durable, with excellent resistance to weathering and impact. GRC precast is often used for exterior building facades, decorative panels, and architectural detailing. In conclusion, both polyurethane precast and GRC precast have their own set of advantages and limitations. The choice between the two depends on the specific requirements of the project, including considerations of weight, thermal insulation, durability, and aesthetic preferences. By understanding the key differences between these materials, construction professionals can select the most appropriate precast solution for their needs.Difference Between Polyurethane Precast and GRC Precast

What is Polyurethane Precast?

What is GRC Precast?

Main Differences

The cost of polyurethane.

Polyurethane is a versatile polymer used in a wide range of products, from foam mattresses to industrial coatings. Its price is influenced by various factors, including raw material costs, demand in different industries, and global economic conditions. This article provides an overview of the factors affecting polyurethane prices and what to expect in the future. The cost of polyurethane is closely tied to the price of its raw materials, primarily isocyanates and polyols, which are derived from crude oil. Therefore, fluctuations in oil prices can significantly affect polyurethane prices. Additionally, demand from key industries such as automotive, construction, and furniture also plays a crucial role. For instance, an upsurge in construction activities can lead to increased demand for polyurethane insulation materials, pushing prices up. Currently, the global market is experiencing moderate fluctuations in polyurethane prices due to the stabilizing oil market and balanced demand-supply dynamics. However, geopolitical tensions, trade policies, and environmental regulations could introduce volatility in the prices. Looking ahead, advancements in bio-based polyurethanes and recycling technologies may offer cost-effective and sustainable alternatives, potentially influencing future pricing trends. Understanding the factors that influence polyurethane prices is essential for businesses and consumers alike. By keeping an eye on oil prices, industry demands, and technological advancements, stakeholders can make informed decisions and anticipate future market movements. While the current market shows relative stability, the potential for fluctuation remains, highlighting the importance of staying informed.Polyurethane Prices: An Overview

Factors Influencing Polyurethane Prices

Current Trends and Future Outlook

Conclusion

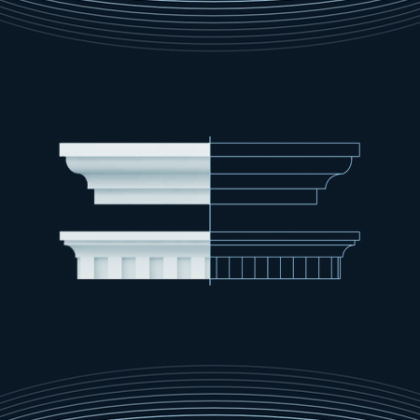

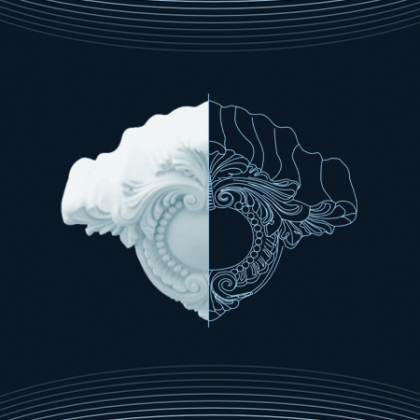

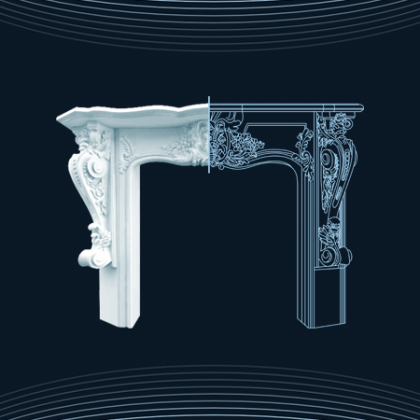

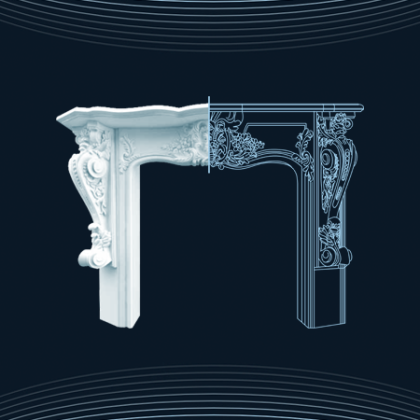

Information Gallery

List of detailed descriptions of images in the image gallery.

English

English

Romanian

Romanian