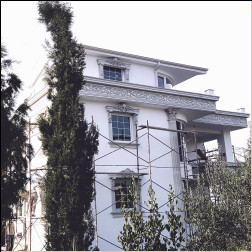

Polyurethane detached house exterior designs refer to styles for standalone homes that use polyurethane materials in their exteriors. These designs involve applying polyurethane products, such as coatings, finishes, or architectural details, to enhance the house's aesthetic appeal and durability.

In the world of modern architecture and design, the exterior of a home is just as important as the interior. One innovative material that is making waves in the realm of detached house exterior designs is polyurethane. This versatile material is not only durable but also offers a wide range of aesthetic possibilities, making it a popular choice among architects and homeowners alike.

Polyurethane is a type of polymer composed of organic units joined by carbamate (urethane) links. It is manufactured by reacting a polyol (alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. The result is a material that can be engineered to exhibit various properties, including flexibility, rigidity, and resistance to wear and environmental factors. This versatility makes polyurethane an ideal material for a wide range of applications, including building exteriors.

The flexibility of polyurethane in terms of both physical properties and aesthetics means that the design possibilities are nearly endless. Architects and designers can create exteriors that are not only visually appealing but also functional and sustainable. Whether aiming for a traditional look with faux-wood siding or a more modern aesthetic with smooth, geometric panels, polyurethane can achieve a variety of styles to suit any taste.

Polyurethane detached house exterior designs offer a modern solution that balances aesthetic appeal with functionality and sustainability. Its durability, versatility, and low maintenance requirements make it a smart choice for homeowners looking to make a long-term investment in their property’s exterior. As technology and material science continue to evolve, it is likely that polyurethane will remain at the forefront of innovative exterior design solutions.

Polyurethane Detached House Exterior Designs

What is Polyurethane?

Advantages of Polyurethane in Exterior Design

Design Possibilities with Polyurethane

Conclusion

Detached house exterior designs have evolved over time, reflecting changes in architectural trends, materials, and homeowners' preferences. They have played a significant role in shaping the visual and cultural landscape of residential areas.

The architectural landscape has been profoundly shaped by the evolution of detached house exterior designs throughout history. From the simple, functional homes of early civilizations to the elaborate and stylistically diverse residences of the modern era, the exterior design of detached houses has reflected changes in technology, culture, and social norms. In ancient times, the design of a detached house was primarily influenced by the local climate and available materials. For instance, in the Mediterranean, houses were often built with thick walls and small windows to keep the interiors cool. The medieval period saw the emergence of the timber-framed houses in Europe, characterized by their wooden beams and plaster exteriors, which were both functional and aesthetically pleasing. The Renaissance era brought about a significant change in detached house exterior designs, with a greater emphasis on symmetry, proportion, and the use of classical architectural elements. This period also saw the rise of the grand country houses, which were as much a statement of wealth and power as they were comfortable living spaces. In the 19th century, the Industrial Revolution led to new building technologies and materials, such as cast iron and steel, allowing for more elaborate and diverse house designs. The 20th century witnessed unprecedented diversity in detached house exterior designs, driven by innovations in architecture and a shift towards individualism. The early part of the century saw the popularity of styles such as Art Deco and Modernism, which emphasized clean lines and functional design. The latter half of the century and into the 21st century has seen a resurgence in traditional and historical styles, alongside the continued development of new, sustainable design practices aimed at reducing the environmental impact of buildings. The history of detached house exterior designs is a rich tapestry that mirrors the broader trends in architecture, society, and technology. As we move forward, it is clear that the design of detached houses will continue to evolve, reflecting new advances in building technology, changing tastes, and the increasing importance of sustainability.Detached House Exterior Designs in History

Ancient and Medieval Periods

Renaissance to the 19th Century

20th Century to Present

Conclusion

Polyurethane in detached house exterior designs offers durability, weather resistance, and energy efficiency. It's used in insulation, sealants, and coatings, enhancing the house's appearance and longevity.

Polyurethane is increasingly becoming a popular choice for detached house exterior designs due to its versatility, durability, and aesthetic appeal. This synthetic material can be molded into various shapes and textures, making it an ideal option for creating unique and eye-catching home exteriors. In this article, we will explore the properties of polyurethane that make it suitable for detached house exterior designs. One of the key properties of polyurethane is its exceptional durability. It is resistant to weather changes, moisture, and even UV rays, ensuring that the exterior of the house remains in pristine condition for years. This makes polyurethane an excellent choice for areas that experience extreme weather conditions. Polyurethane also provides excellent insulation, helping to keep the interior of the house warm in winter and cool in summer. This can lead to significant energy savings, making polyurethane a cost-effective option for exterior design. Thanks to its moldable nature, polyurethane can be crafted into a wide range of designs, from traditional to modern. Whether homeowners are looking for intricate decorative elements or sleek, contemporary lines, polyurethane can be adapted to meet these design needs. This flexibility allows for the creation of unique and personalized home exteriors. Another advantage of using polyurethane for detached house exteriors is its low maintenance requirements. Unlike natural materials that may need regular treatments and repairs, polyurethane surfaces are easy to clean and maintain, requiring only occasional washing to keep them looking new. For those concerned about the environmental impact of their design choices, there are eco-friendly polyurethane options available. These are typically made from renewable resources and are designed to be recyclable, reducing the carbon footprint of the home. In conclusion, polyurethane offers a range of properties that make it an attractive option for detached house exterior designs. Its durability, insulation capabilities, design flexibility, ease of maintenance, and eco-friendly options make it a versatile choice for any homeowner looking to enhance the aesthetic appeal and functionality of their home.Polyurethane Detached House Exterior Designs

Durability and Weather Resistance

Insulation Properties

Design Flexibility

Easy Maintenance

Eco-Friendly Options

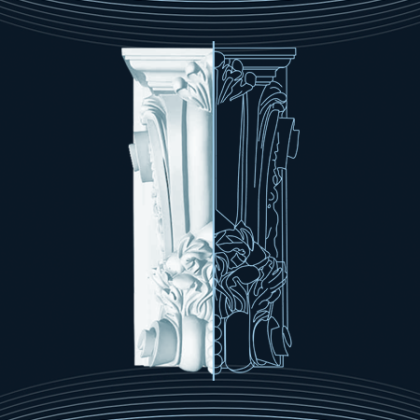

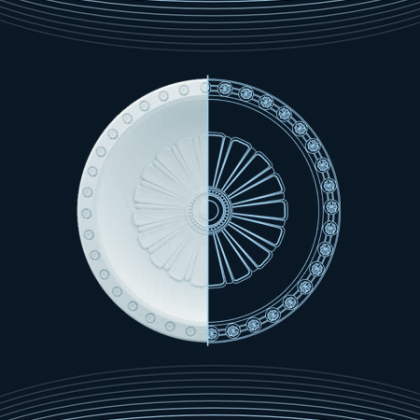

Are the applications of polyurethane in the decoration of detached house exteriors distinct?

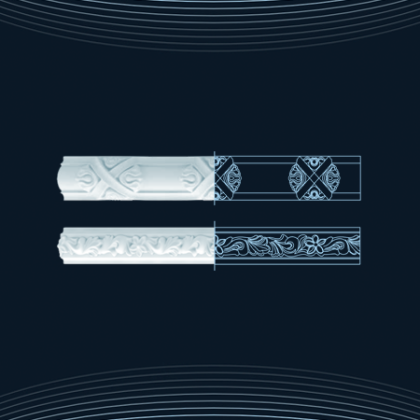

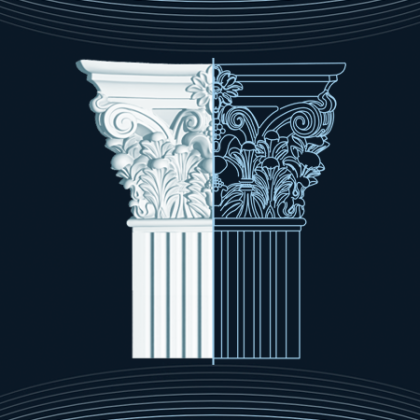

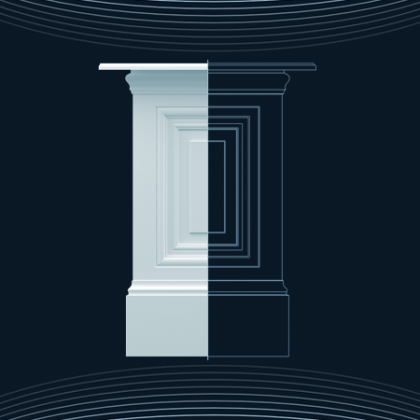

Polyurethane is a versatile and durable material that has found extensive usage in various sectors, including construction and decoration. Its application in detached house exterior designs has been growing, thanks to its flexibility, durability, and aesthetic appeal. This article explores the different usage areas of polyurethane in the decoration of detached house exteriors. One of the primary applications of polyurethane in detached house exteriors is insulation. Polyurethane foam is an excellent insulator, helping to keep homes warmer in winter and cooler in summer. This not only enhances comfort but also contributes to energy efficiency, leading to lower heating and cooling costs. Polyurethane can be molded into various shapes and designs, making it a popular choice for decorative elements on house exteriors. From intricate moldings and trims to faux stone and wood finishes, polyurethane allows homeowners to achieve a desired look without the weight and cost of natural materials. Exterior decorations made from polyurethane are known for their durability. They are resistant to moisture, rot, and insects, which are common issues with natural materials. Additionally, polyurethane finishes require minimal maintenance, retaining their appearance for years with little need for repairs or repainting. The flexibility of polyurethane as a material means it can be customized to fit any architectural style or homeowner's preference. Whether it's for modern, contemporary, or traditional designs, polyurethane can be shaped and colored to complement any exterior aesthetic. The usage areas of polyurethane in detached house exterior designs are diverse and beneficial. From providing effective insulation and energy efficiency to enhancing aesthetic appeal with customizable designs, polyurethane is a material that offers both practical and decorative advantages. Its durability and low maintenance further make it an ideal choice for homeowners looking to beautify their exteriors with long-lasting, high-quality finishes.Polyurethane in Detached House Exterior Designs

Insulation and Energy Efficiency

Aesthetic Appeal

Durability and Maintenance

Customization and Flexibility

Conclusion

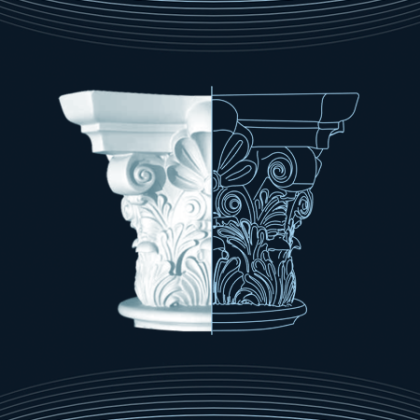

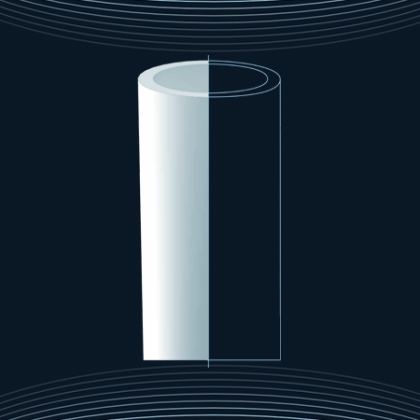

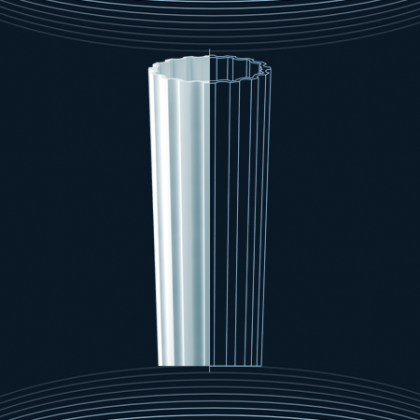

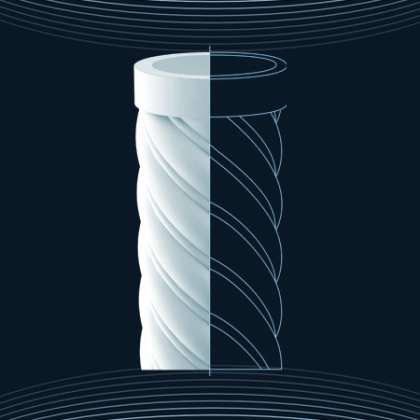

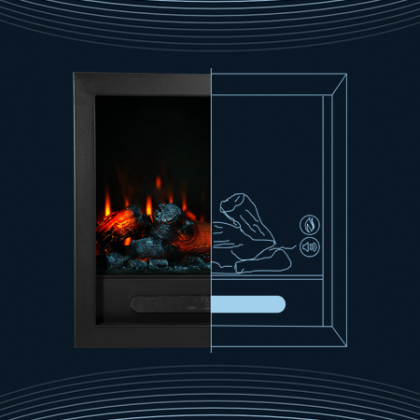

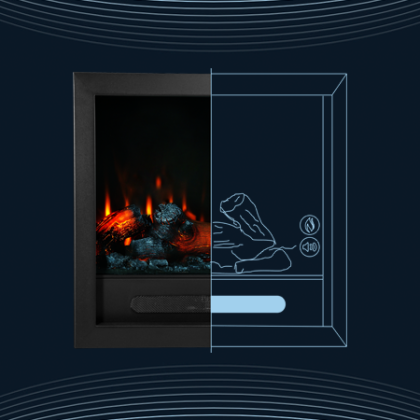

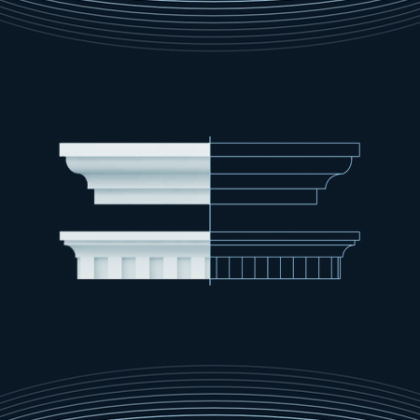

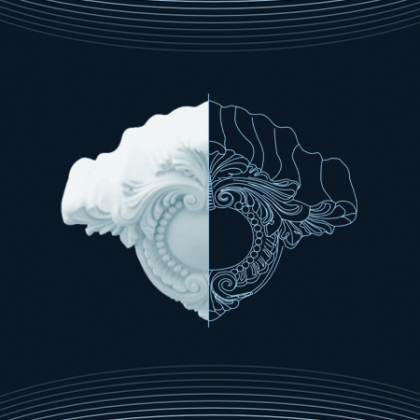

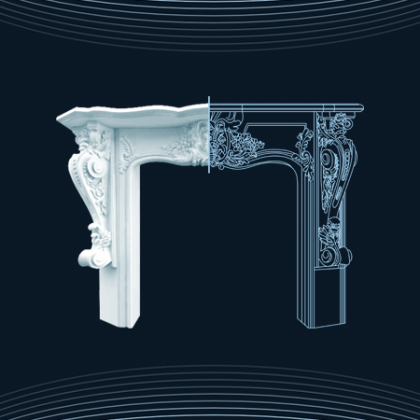

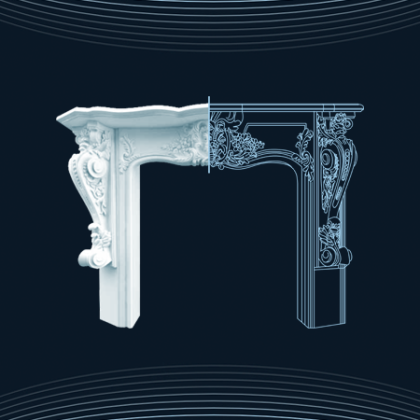

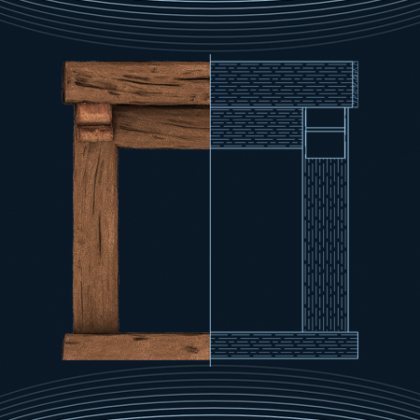

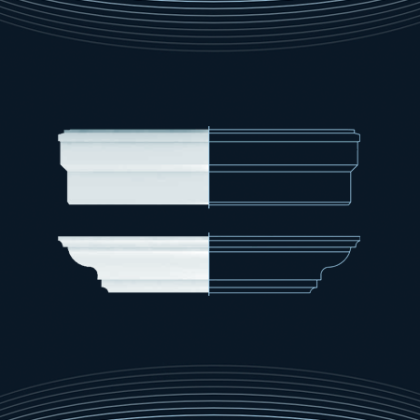

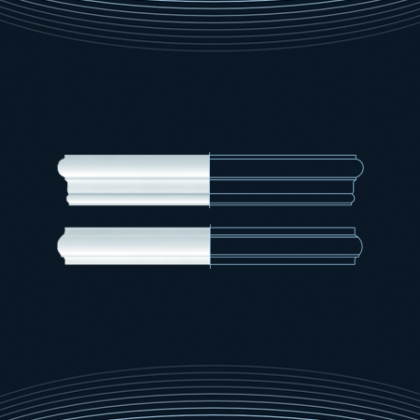

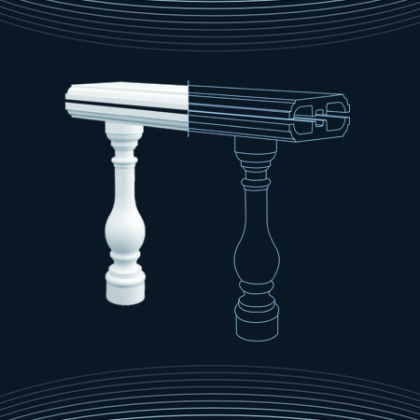

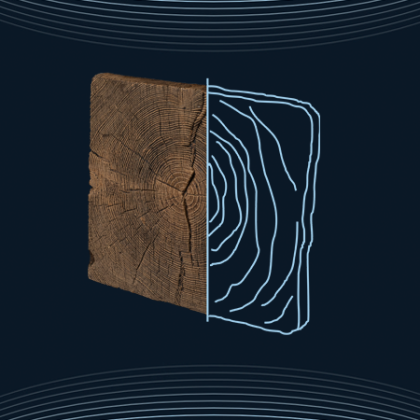

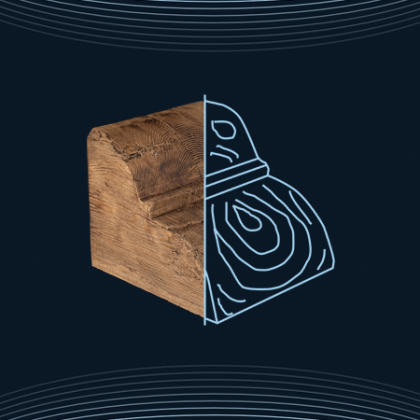

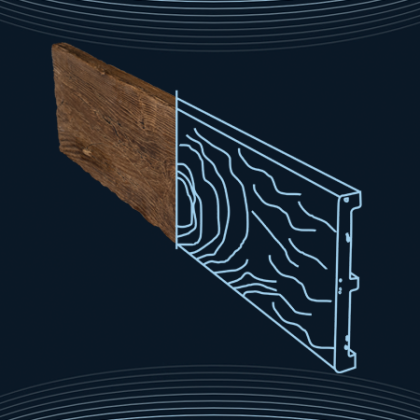

Models of detached house exterior designs using polyurethane.

In the world of modern architecture, polyurethane has emerged as a versatile and durable material for exterior designs, especially for detached houses. This innovative material offers a wide range of benefits, including energy efficiency, durability, and an aesthetic appeal that can be tailored to suit any architectural style. Let's explore some of the cutting-edge models and designs that incorporate polyurethane in detached house exteriors. Polyurethane is known for its excellent insulation properties, which can significantly reduce heating and cooling costs in a home. Moreover, it is resistant to weather changes, moisture, and pests, ensuring a long-lasting exterior without the need for frequent maintenance. Its versatility allows for a variety of textures and finishes, from smooth and sleek to textured that mimic traditional materials like wood and stone. Architects and designers are increasingly incorporating polyurethane into their projects due to its flexibility in design and superior performance. Here are some innovative models: Polyurethane detached house exterior designs offer a blend of functionality, durability, and style. Whether you're aiming for a modern minimalist look, a traditional aesthetic, or an eco-friendly design, polyurethane provides the flexibility to bring your vision to life. As technology and materials continue to evolve, we can expect to see even more innovative and sustainable designs in the future.Polyurethane Detached House Exterior Designs

Why Choose Polyurethane?

Innovative Designs with Polyurethane

Conclusion

Can polyurethane be used for the exterior walls of detached houses?

When it comes to detached house exterior designs, homeowners and architects are constantly looking for materials that combine aesthetics, durability, and energy efficiency. Polyurethane has emerged as a versatile and innovative solution for exterior walls, offering numerous benefits that cater to modern design needs. Polyurethane is a type of plastic that can be both rigid and flexible, making it an ideal material for a variety of applications, including exterior wall insulation and finishes. Its popularity in detached house exterior designs stems from its excellent insulation properties, which can significantly reduce energy costs. Additionally, polyurethane is known for its durability, resistance to weather, and ease of maintenance, making it a practical choice for exterior walls. In the context of detached house exterior designs, polyurethane can be used in several ways. It is often applied as a form of spray foam insulation, providing a high-performance solution that seals the building envelope against air and moisture infiltration. This not only enhances the home's energy efficiency but also contributes to a more comfortable indoor environment. Beyond insulation, polyurethane finishes are available in various textures and colors, allowing for a wide range of aesthetic options. These finishes can mimic the appearance of traditional materials like wood, stone, or brick, while offering the added benefits of polyurethane's durability and low maintenance requirements. This makes it an attractive option for homeowners looking to achieve a specific look without the upkeep associated with natural materials. While polyurethane offers many advantages for detached house exterior designs, there are some considerations to keep in mind. The installation of polyurethane products, particularly spray foam insulation, should be carried out by professionals to ensure optimal performance and safety. Additionally, homeowners should be aware of the initial costs, which may be higher than traditional materials, though the long-term savings on energy bills can offset this. In conclusion, polyurethane is a versatile and effective material for detached house exterior designs, offering a blend of aesthetic flexibility, durability, and energy efficiency. With proper installation and care, it can enhance the appearance and performance of a home's exterior for years to come.Polyurethane in Detached House Exterior Designs

Why Polyurethane?

Applications in Exterior Designs

Considerations

Yes, the exterior designs of detached houses made from polyurethane can be painted.

When it comes to renovating or refreshing the exterior of a detached house, homeowners often explore various materials and finishes to enhance their property's curb appeal. Polyurethane, known for its durability and versatility, is a popular choice for exterior designs, including trim, moldings, and even entire façade coverings. A common question that arises is whether polyurethane surfaces can be painted to fit a homeowner's aesthetic preferences or to update the look of the house. The short answer is yes. Polyurethane exterior designs can indeed be painted, which allows for a wide range of customization options. Painting polyurethane is a viable way to match the exterior elements to the overall color scheme of the house or to give your home a fresh, new look. However, to ensure a successful application and lasting finish, there are several important steps and considerations to keep in mind. Before painting polyurethane, the surface must be properly prepared to ensure the paint adheres well and lasts long. This usually involves cleaning the surface thoroughly to remove any dirt, grease, or existing paint. Light sanding may also be necessary to create a rougher surface that allows the new paint to adhere better. Not all paints are suitable for use on polyurethane. Acrylic latex paint is often recommended for its durability and ease of use. It's important to choose a high-quality exterior paint that can withstand the elements and adhere well to polyurethane surfaces. Applying a primer designed for use on plastic or synthetic surfaces can also enhance the paint's adhesion and overall finish. For the best results, applying the paint with a high-quality brush, roller, or sprayer is recommended. Each method has its advantages, but ensuring even coverage and avoiding drips or brush marks is essential. In some cases, applying multiple thin coats may yield better results than a single thick coat. Once painted, polyurethane exterior designs will require periodic maintenance to keep them looking their best. This may include cleaning the surfaces regularly to remove dirt and debris and touching up any areas where the paint has chipped or worn away over time. In conclusion, painting polyurethane exterior designs on detached houses is not only possible but also a great way to customize and refresh the look of your home. With proper preparation, the right materials, and careful application, homeowners can achieve a durable and aesthetically pleasing finish that enhances their property's curb appeal.Painting Polyurethane Exterior Designs on Detached Houses

Can Polyurethane Be Painted?

Preparation is Key

Choosing the Right Paint

Application Techniques

Maintenance and Upkeep

Applying polyurethane to the exterior of a detached house involves these steps: 1. Prepare the surface by cleaning and sanding. 2. Apply a thin coat of polyurethane using a brush or sprayer. 3. Let it dry completely. 4. Sand lightly between coats. 5. Apply additional coats for desired protection.

Applying polyurethane to the exterior of a detached house can significantly enhance its durability and aesthetic appeal. This versatile coating not only protects the exterior surfaces from harsh weather conditions but also gives them a glossy finish that can elevate the overall look of your home. Here’s a step-by-step guide on how to apply polyurethane for an impeccable exterior design. Before applying polyurethane, it's crucial to prepare the surface properly. Start by cleaning the exterior walls to remove any dirt, grime, or loose paint. For wooden surfaces, sanding might be necessary to ensure a smooth application. Make sure the surface is completely dry before proceeding. There are two main types of polyurethane: water-based and oil-based. Water-based polyurethane is easier to apply, dries faster, and has a lower odor, making it ideal for exterior surfaces. However, oil-based polyurethane is more durable and better suited for areas that are exposed to direct sunlight or extreme weather conditions. Applying polyurethane can be done using a brush, roller, or sprayer. For large, exterior surfaces, using a sprayer can significantly reduce the application time. Apply the polyurethane in thin, even coats, ensuring that you cover all areas uniformly. Avoid applying too much product at once to prevent drips and uneven layers. After the first coat has been applied, allow it to dry completely according to the manufacturer's instructions. This could take anywhere from a few hours to overnight. Once dry, inspect the surface for any missed spots or uneven areas. If necessary, lightly sand the surface before applying a second coat. Two to three coats are usually sufficient for a durable and visually appealing finish. Maintaining the polyurethane finish is essential for prolonging its life and keeping your home looking its best. Regularly clean the coated surfaces to remove dirt and debris. Inspect the exterior yearly and touch up any areas where the polyurethane has worn away to ensure continuous protection. By following these steps, you can apply polyurethane to your detached house exterior, ensuring a durable and attractive finish that will protect your home for years to come.Applying Polyurethane on Detached House Exteriors

Preparation

Choosing the Right Polyurethane

Application

Drying and Reapplication

Maintenance

Polyurethane detached house exterior designs use a type of durable plastic for decoration and insulation, offering a strong, weather-resistant finish. Styrofoam detached house exterior designs, on the other hand, use a lightweight foam for insulation and design purposes, which is less durable and offers lower resistance to weather conditions.

When it comes to detached house exterior designs, choosing the right material for insulation and aesthetics is crucial. Two popular options are polyurethane and styrofoam. This article explores the differences between these materials in the context of detached house exterior designs. Polyurethane is a type of plastic that can be either rigid or flexible. For exterior house designs, rigid polyurethane foam is used for insulation purposes. It is known for its excellent thermal insulation properties, durability, and strength. Polyurethane is also moisture-resistant, making it an ideal choice for exterior applications. Its versatility allows for creative and varied architectural designs, including intricate details and shapes. Styrofoam, a brand name for extruded polystyrene foam (XPS), is another popular material for exterior house designs. It is lightweight, making it easy to handle and install. Styrofoam provides good thermal insulation and is also moisture-resistant. However, it is less durable than polyurethane and may be more susceptible to damage from physical impact or harsh weather conditions. Styrofoam can be used for a variety of design elements, including decorative trim and molding. While both materials offer good insulation and moisture resistance, there are key differences. Polyurethane is more durable and offers superior insulation compared to Styrofoam. It can also support more weight, making it suitable for structural applications in exterior designs. On the other hand, Styrofoam is lighter and easier to work with, which can be advantageous for certain design elements and installations. In conclusion, the choice between polyurethane and Styrofoam for detached house exterior designs depends on specific project requirements, including durability, insulation needs, and design complexity. Polyurethane is preferable for projects requiring superior insulation and strength, while Styrofoam is suitable for lighter, decorative applications.Polyurethane vs Styrofoam Detached House Exterior Designs

Introduction

Polyurethane Exterior Designs

Styrofoam Exterior Designs

Comparison

Conclusion

Polyurethane exterior designs for detached houses involve using a type of durable, synthetic material that can mimic the look of wood, stone, or other textures. This material is lightweight, resistant to weather, and easy to maintain. Plaster exterior designs, on the other hand, use a mixture of lime, sand, and water applied over mesh to create a smooth or textured finish on the outside of a house. Plaster is traditional, offers a classic look, and can be painted in any color but requires more maintenance and is less durable against harsh weather conditions.

When it comes to detached house exterior designs, both polyurethane and plaster offer unique benefits and aesthetic appeal. However, they are distinct materials with different properties, applications, and effects on the overall look and durability of the house exterior. Understanding these differences is crucial for homeowners and designers making decisions about exterior finishes. Polyurethane is a type of plastic that can be either rigid or flexible. It is commonly used in exterior designs as moldings, trim, and decorative elements. Polyurethane is lightweight, resistant to weather and pests, and easy to install. It can mimic the look of wood, stone, or other materials, providing versatility in design. Plaster, on the other hand, is a mixture of water, sand, and a binder like lime or gypsum. It has been used for centuries in building exteriors for its durability and ability to be molded into decorative shapes. Plaster application is labor-intensive, requiring skilled craftsmanship to apply and shape it on the house exterior. Polyurethane is highly durable, resistant to rot, moisture, and insects, making it a low-maintenance option for homeowners. Its durability also means it can withstand extreme weather conditions without deteriorating quickly. Plaster, while durable and able to last for decades, requires more maintenance to keep it in good condition. It is susceptible to cracking and needs to be painted or sealed to protect it from moisture and weathering. The aesthetic appeal of polyurethane and plaster differs significantly. Polyurethane can be crafted to closely resemble materials like wood and stone, offering a wide range of design possibilities. Its precision and uniformity can give the exterior a clean, modern look. Plaster provides a classic, timeless appearance. Its texture and the craftsmanship involved in its application add character and depth to the exterior design. Plaster can also be painted in any color, offering flexibility in matching or complementing the house's overall color scheme. Polyurethane, being a plastic-based material, is not biodegradable and can be more harmful to the environment. However, its durability and longevity might offset its environmental impact over time. Plaster is more environmentally friendly, made from natural materials. It is also breathable, allowing for better air quality and moisture regulation within the home. Choosing between polyurethane and plaster for detached house exterior designs depends on several factors, including desired aesthetic, maintenance willingness, environmental considerations, and budget. Both materials offer distinct advantages, and the best choice varies depending on the specific needs and preferences of the homeowner.Differences Between Polyurethane and Plaster in Detached House Exterior Designs

Material Composition and Application

Durability and Maintenance

Aesthetic Appeal

Environmental Considerations

Conclusion

Polyurethane precast is made from a type of plastic that's strong and lightweight. GRC precast, which stands for Glassfiber Reinforced Concrete, is made from a mix of cement and glass fibers, making it tough and durable.

In the world of construction, materials play a pivotal role in defining the durability, aesthetics, and functionality of a structure. Two such materials that have gained popularity for their use in precast applications are Polyurethane (PU) and Glassfibre Reinforced Concrete (GRC). Though both materials are used in precast form, they have distinct characteristics, applications, and benefits. This article aims to explore the differences between polyurethane precast and GRC precast to provide a clearer understanding for architects, builders, and developers. Polyurethane precast refers to the use of polyurethane, a type of polymer, in the creation of building elements that are molded off-site. Polyurethane is known for its lightweight, flexibility, and excellent insulation properties. It can mimic the appearance of more traditional materials like wood, stone, or brick, and is often used for decorative elements, moldings, and façade panels. GRC precast, or Glassfibre Reinforced Concrete precast, combines concrete with glass fiber reinforcements. This material is known for its high strength-to-weight ratio, durability, and fire resistance. GRC can be molded into a wide variety of shapes and textures, making it suitable for a range of architectural applications, including cladding panels, architectural molding, and decorative features. In conclusion, both polyurethane precast and GRC precast have their unique advantages and disadvantages. The choice between the two materials depends on the specific requirements of the project, including considerations of weight, durability, design flexibility, insulation needs, and environmental impact. Understanding the key differences between these two materials can help in making an informed decision that aligns with the project's goals.Difference Between Polyurethane Precast and GRC Precast

Introduction

What is Polyurethane Precast?

What is GRC Precast?

Key Differences

Conclusion

Prices for exterior designs of detached houses using polyurethane.

In recent years, the popularity of polyurethane in detached house exterior designs has surged due to its durability, insulation properties, and aesthetic flexibility. This material allows homeowners to achieve a variety of looks, from traditional stucco to modern, sleek finishes, while also enhancing the home's energy efficiency. This article explores the range of polyurethane exterior designs for detached houses and provides an overview of pricing. Polyurethane is renowned for its insulation qualities, which can significantly reduce heating and cooling costs. It is also lightweight, which makes it easy to install, and it is resistant to mold, mildew, and pests. Its versatility in texture and color allows for a wide range of design options, catering to various architectural styles and homeowner preferences. When it comes to detached house exterior designs, polyurethane can be molded into virtually any shape and texture, mimicking materials like wood, stone, and brick. This provides homeowners with the freedom to choose designs that complement their home’s architecture and the surrounding landscape. Some popular design options include: The cost of polyurethane exterior designs can vary widely depending on the complexity of the project, the quality of materials, and labor costs in your area. On average, homeowners can expect to spend between $5 to $10 per square foot for basic polyurethane panels. Custom designs, intricate textures, and additional features like insulation can increase the price. Installation costs also vary but can range from $2 to $5 per square foot. It's essential to consult with a professional to get an accurate estimate for your specific project. Polyurethane exteriors offer a durable, energy-efficient, and versatile option for detached house designs. While the initial investment may be higher than some traditional materials, the long-term savings in energy costs and maintenance can make it a cost-effective choice. With a wide range of design options available, homeowners can achieve the perfect look for their homes while enjoying the benefits of modern material technology.Polyurethane Detached House Exterior Designs and Prices

Benefits of Polyurethane Exteriors

Design Options

Price Overview

Conclusion

Information Gallery

List of detailed descriptions of images in the image gallery.

English

English

Romanian

Romanian