Products

Polyurethane Panel P180120BU: Transformative Panels - Balancing Aesthetics and Performance in Decor Design Ideas

137.04 lei 123.34 lei

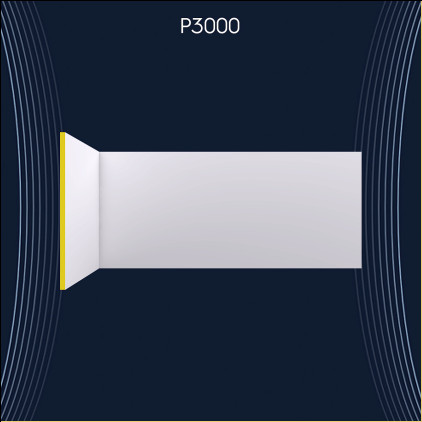

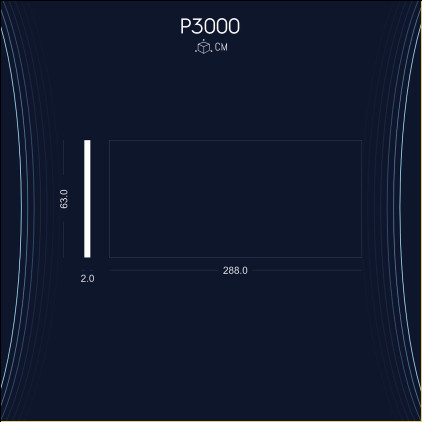

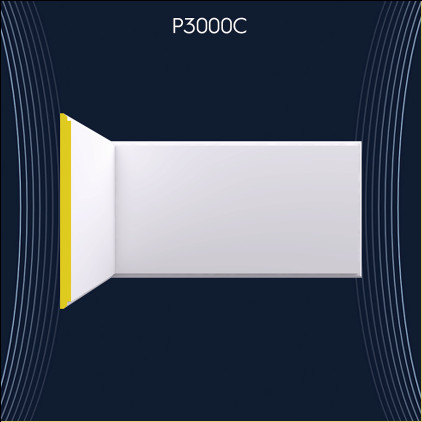

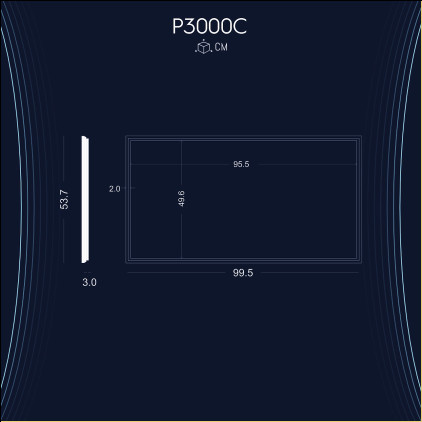

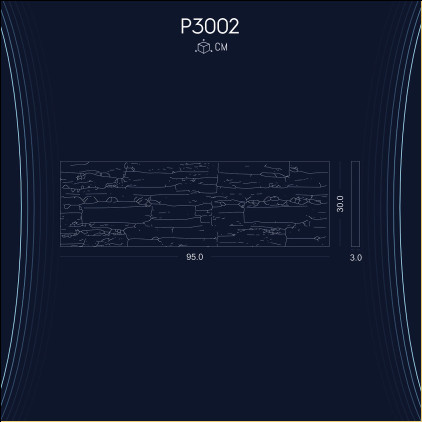

P3000 Polyurethane Panels: Various Applications of Decorative Polyurethane Panels, Design Models and Decoration Ideas

181.81 lei 163.63 lei

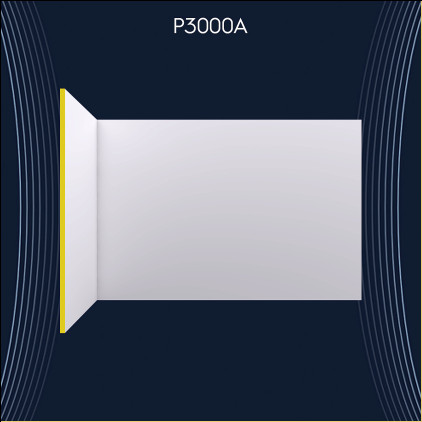

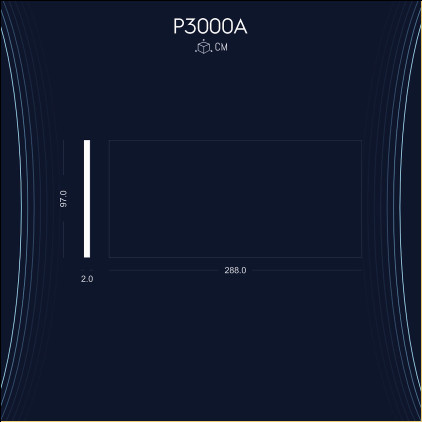

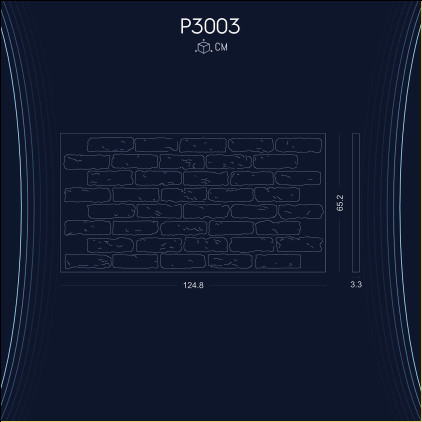

Polyurethane Panel P3000A: Innovative Interior and Exterior Design Ideas with Polyurethane Decoration Models

269.65 lei 242.69 lei

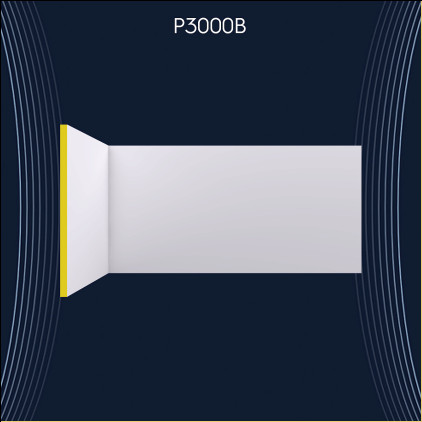

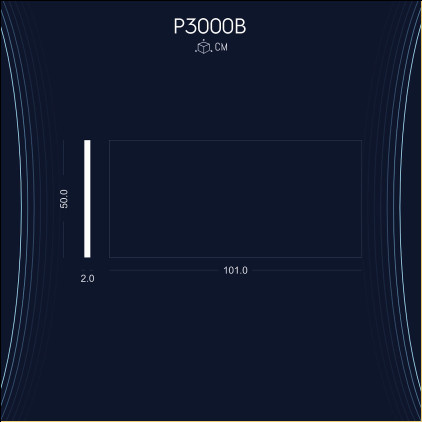

Polyurethane Panel P3000B: How to Choose the Right Decorative Panel for Your Home? Decoration Models, Design Ideas and Examples

144.84 lei 130.36 lei

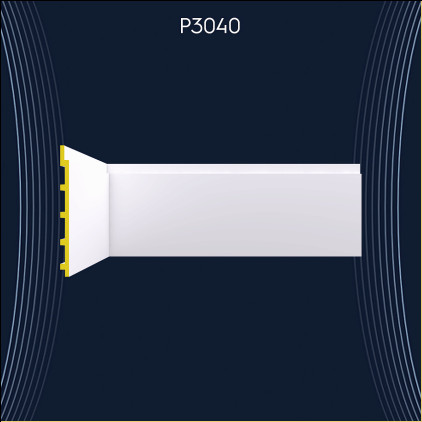

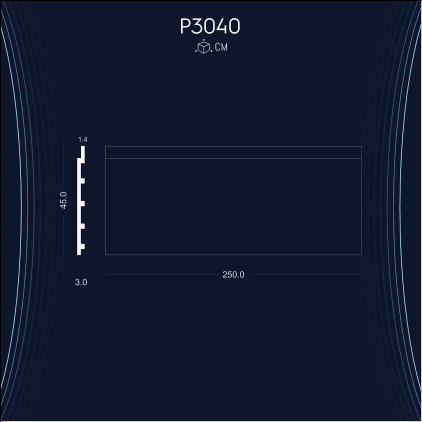

Polyurethane Panel P3040: Stunning Evolution in Interior and Exterior Design - Decoration Models, Ideas, and Inspirations

162.80 lei 146.52 lei

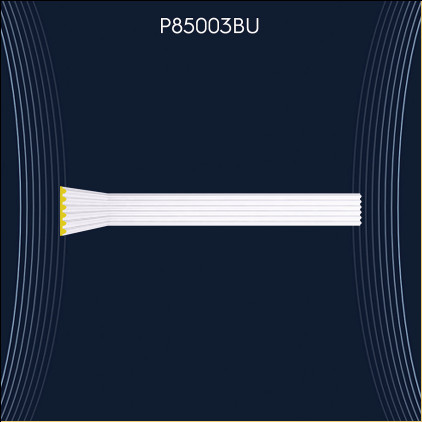

High-Quality Polyurethane Panel P85003BU - Modern Design Decor Ideas with Advanced Technology

122.83 lei 110.55 lei

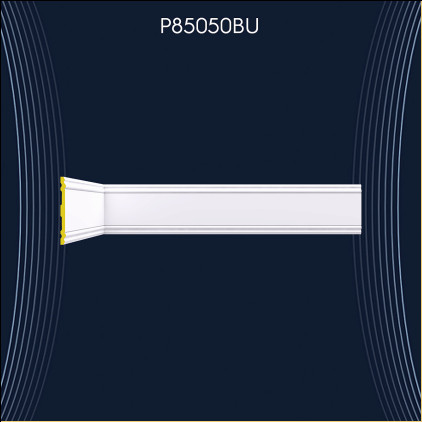

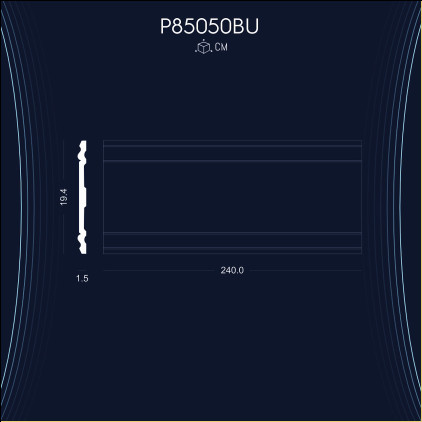

Polyurethane Panel P85050BU: Superior Insulation with Polyurethane Panels - Functional Benefits, Design Ideas, and Decor Models

92.58 lei 83.32 lei

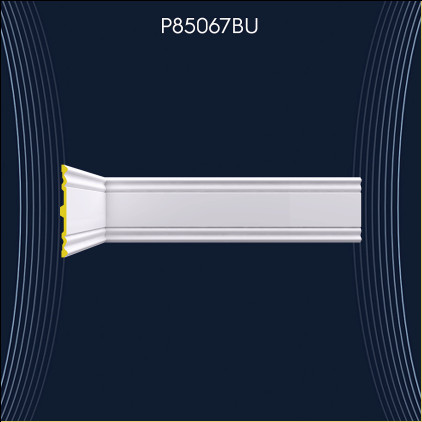

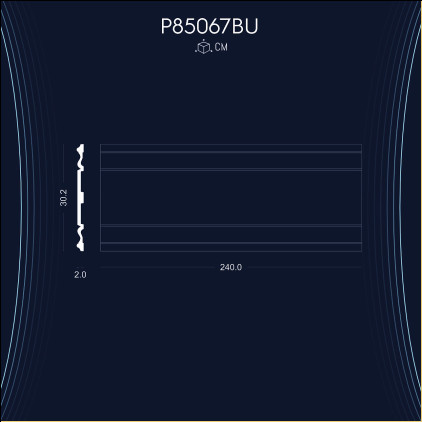

PU Panel P85067BU Polyurethane Decorative Panels - Contemporary Spaces Model P85067BU Decoration Designs Ideas and Samples

127.88 lei 115.09 lei

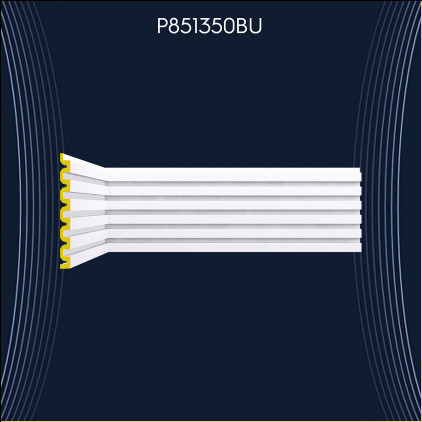

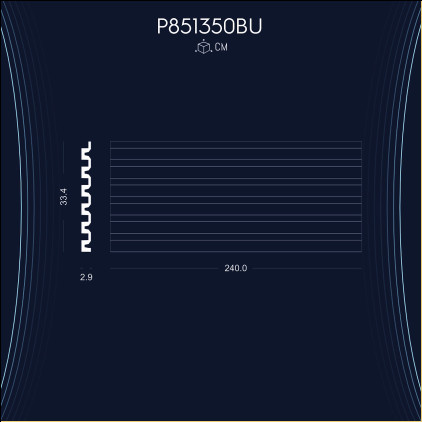

Eco-Friendly and Durable Polyurethane Panel P851350BU - Easy Maintenance Decor Ideas and Designs

245.21 lei 196.17 lei

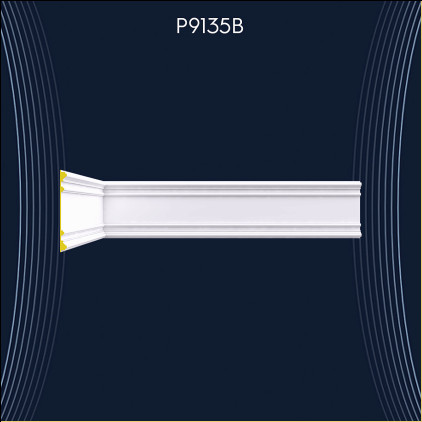

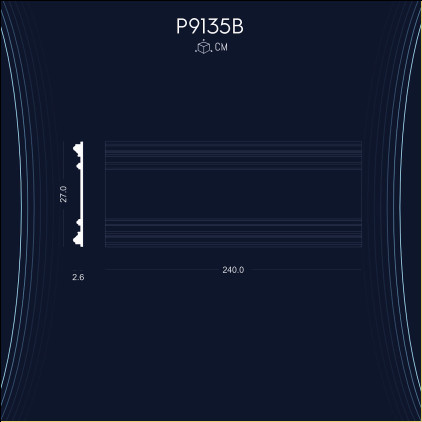

Polyurethane Panel P9135B: Innovative Screen Technology in Decorative Designs - Inspiration and Ideas for Home Decor

168.67 lei 151.80 lei

Polyurethane Patterned Pilaster Column P5014: Diverse Coatings - Imitation Wood/Stone, Custom Painting Decoration Designs and Ideas

169.40 lei 152.46 lei

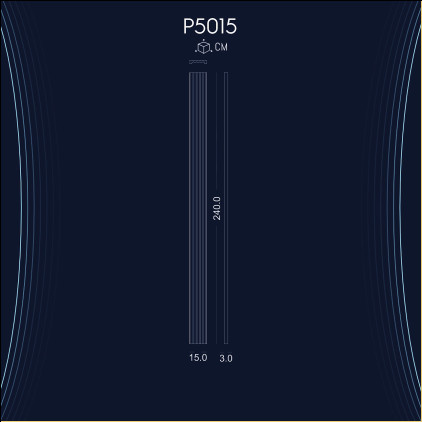

Discover the Elegance and Durability of P5015 Polyurethane Pilaster Columns: Design Ideas and Models for Decorative Inspiration

226.60 lei 203.94 lei

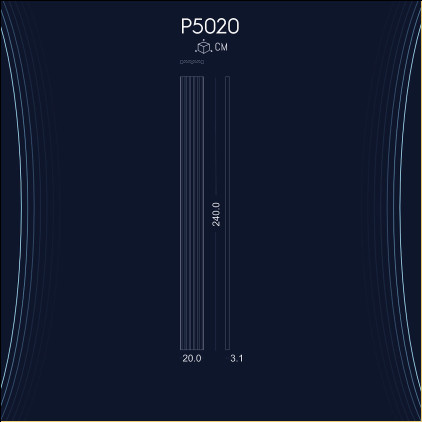

Customize Your Column with P5020 Patterned Polyurethane Pilasters - Decorative Polyurethane Capitals: Design Ideas and Models for Decoration

302.50 lei 272.25 lei

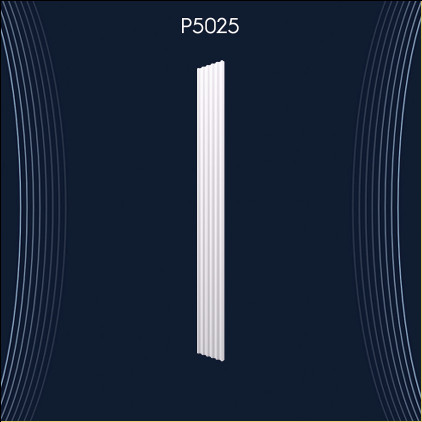

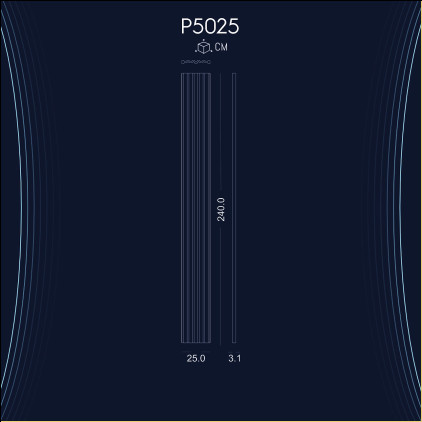

Polyurethane Patterned Pilaster Column P5025: Affordable Luxury and Elegance in Home Decor Designs and Ideas

454.30 lei 408.87 lei

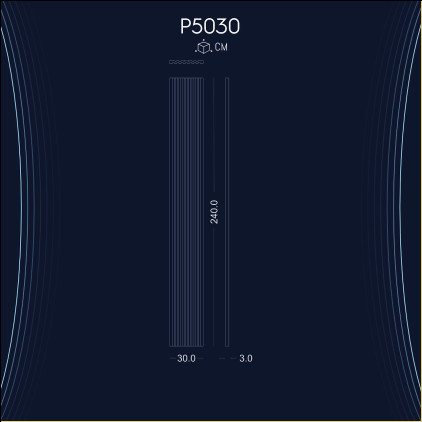

Elegant Ottoman Patterned Polyurethane Pilaster Columns P5030 - Stylish and Decorative Polyurethane Column Designs for Home Decor Ideas

634.70 lei 571.23 lei

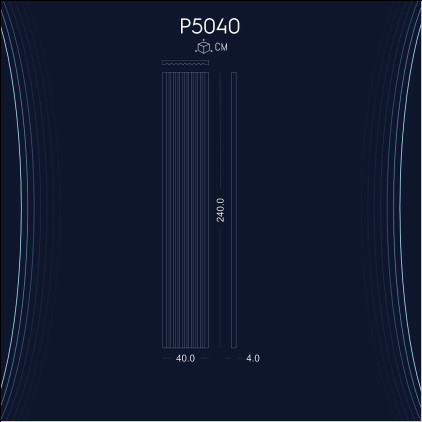

P5040 Polyurethane Patterned Pilaster Columns: Versatile Applications and Benefits in Design Models and Decoration Ideas

811.80 lei 730.62 lei

Polyurethane Patterned Pilaster Columns P5060: Ideal Budget-Friendly Decorative Column Designs for Every Home

1,279.30 lei 1,151.37 lei

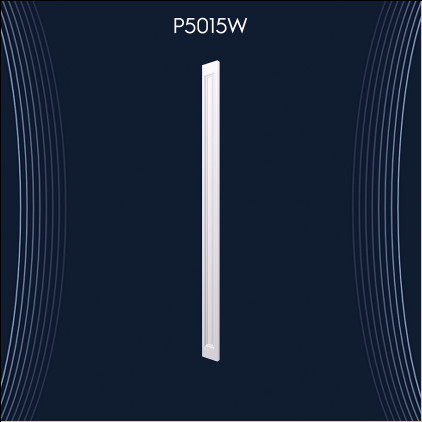

Polyurethane Pilaster Column P5015W: Durability and Aesthetic Design Ideas for Polyurethane Columns and Pilasters

249.70 lei 224.73 lei

Transform Your Space with Polyurethane Pilaster Column Panel P5030W: Design Models and Decoration Ideas

658.90 lei 593.01 lei

Polyurethane Pilaster Panel Column P5040W: Elegance in Various Contexts with Design Models and Decoration Ideas

1,016.40 lei 914.76 lei

Polyurethane Pilaster Column Panel P5060W: Durability Against Environmental Factors - Interior and Exterior Decoration Design Ideas and Inspirations

1,611.50 lei 1,450.35 lei

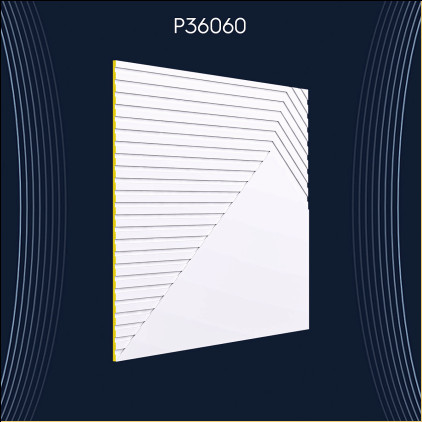

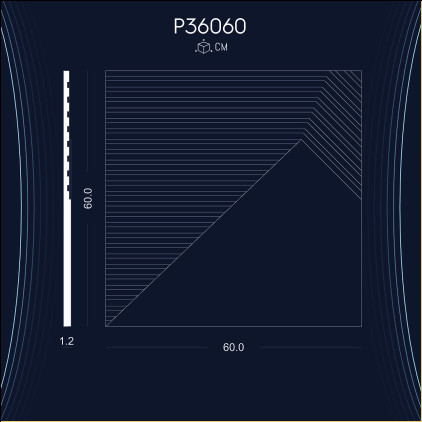

Polyurethane DECOUPE PANEL P312020: Durability Benefits Over Traditional Materials, Design Models, and Decoration Ideas

102.30 lei 92.07 lei

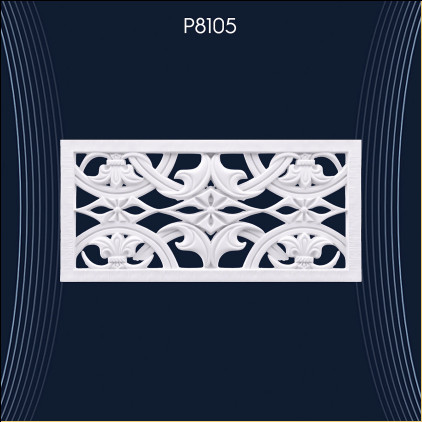

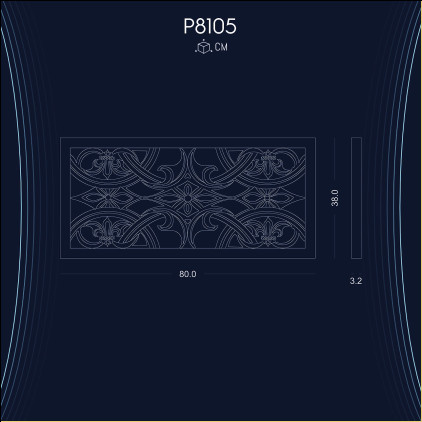

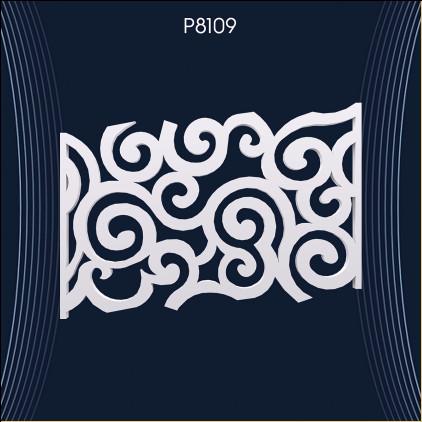

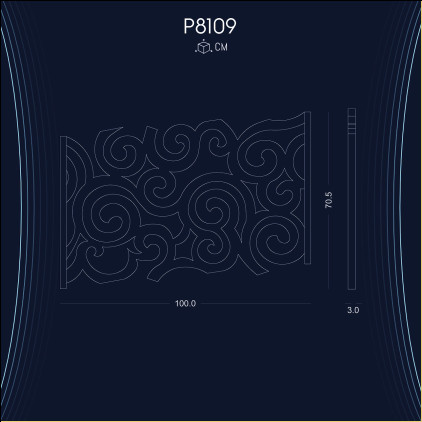

Polyurethane DECOUPE PANEL P8105: Versatile and 3D Design Decor Models - Inspiration and Ideas

203.85 lei

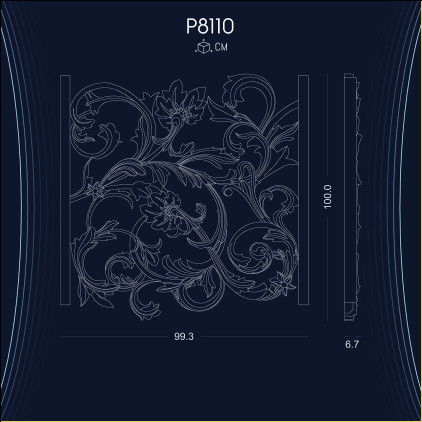

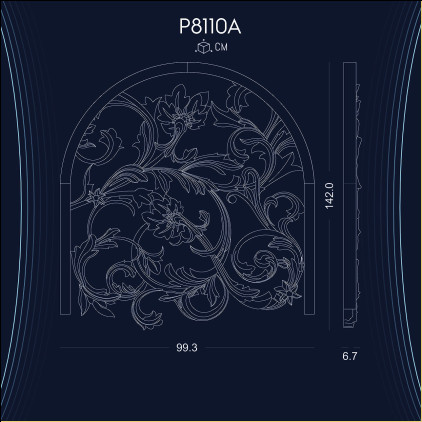

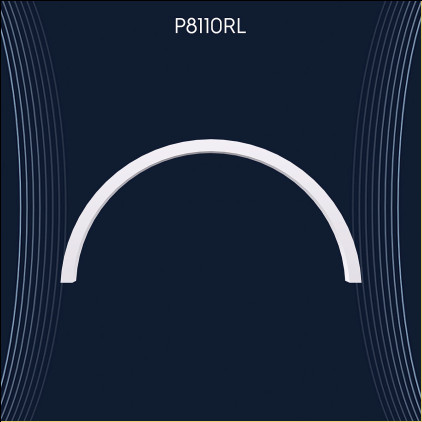

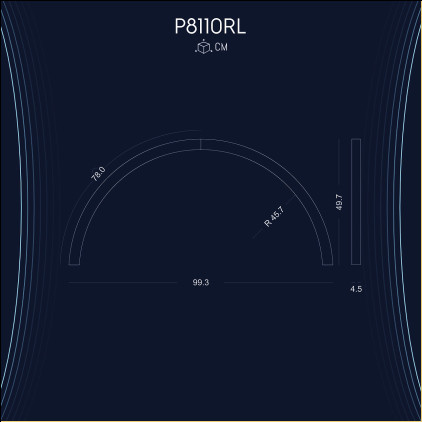

P8110 Polyurethane Decoupage Panels: Innovation and Elegance in Decorative Design Ideas

1,351.88 lei

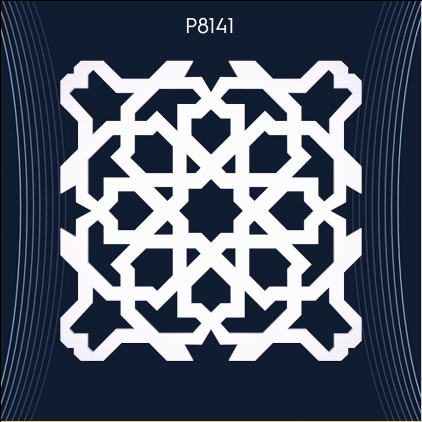

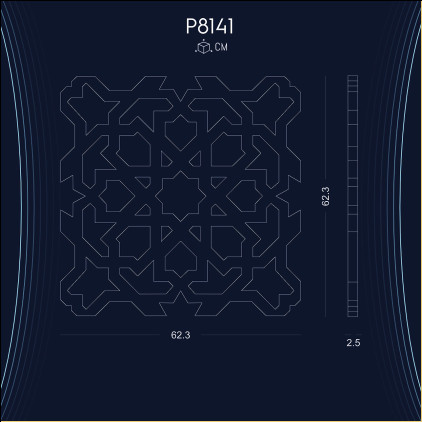

High-Quality Polyurethane Decorative Panels P8141: Design Models and Decoration Ideas

250.35 lei

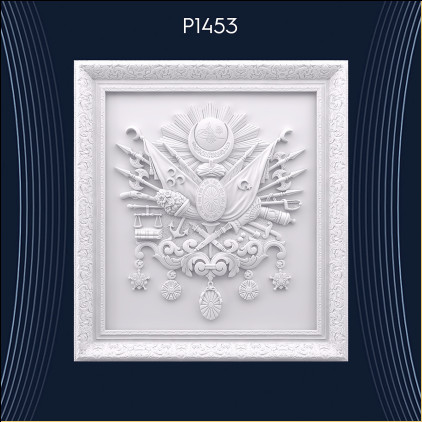

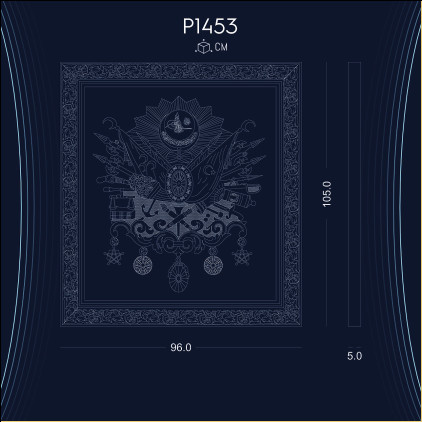

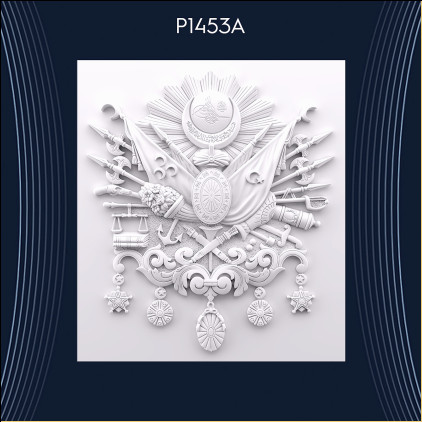

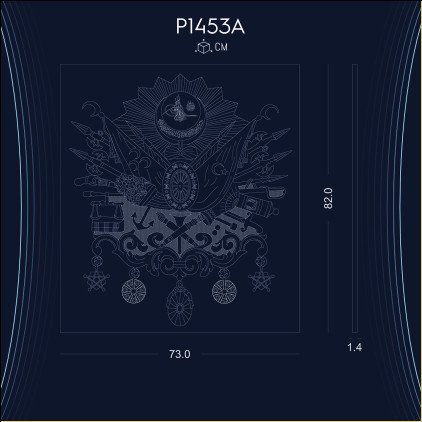

Polyurethane Decoupage Panel P1453: Easy Installation and Maintenance for Decorative Designs

1,431.43 lei

Polyurethane interior and exterior wall facade coating products, including polyurethane exterior panel coating, refer to protective and decorative finishes applied to walls and panels outside and inside buildings. These coatings are made from polyurethane, a type of plastic that forms a durable, resistant layer, protecting surfaces from weather, wear, and enhancing their appearance.

Polyurethane coatings have become a popular choice for protecting and enhancing the aesthetic appeal of interior and exterior walls. These coatings are known for their durability, resistance to environmental factors, and versatility. In this article, we will explore the benefits and applications of polyurethane facade coating products, focusing on polyurethane exterior panel coatings. Polyurethane coatings are suitable for a wide range of applications, both in residential and commercial settings. They can be applied to various substrates, including concrete, metal, and wood, making them a versatile choice for: Specifically, polyurethane exterior panel coatings are designed to offer enhanced protection and aesthetic appeal to building exteriors. These coatings are applied to panels that are then installed on the exterior of buildings, providing a modern look and long-lasting protection. Polyurethane interior and exterior wall facade coatings offer an excellent solution for protecting and enhancing the aesthetic appeal of buildings. Their durability, weather and chemical resistance, and aesthetic flexibility make them a preferred choice for a wide range of applications. Whether for residential or commercial buildings, polyurethane coatings provide a modern, durable, and visually appealing finish.Polyurethane Coating for Interior and Exterior Walls

Introduction

Benefits of Polyurethane Coatings

Applications of Polyurethane Coatings

Conclusion

The place of Interior & Exterior Wall Polyurethane Facade Coating Products, including Polyurethane Exterior Panel Coating, in history is as materials used for protecting and enhancing the appearance of building exteriors.

Polyurethane facade coating products, encompassing both interior and exterior wall applications, have carved a significant place in the history of architectural materials. Originating in the mid-20th century, these coatings have evolved from basic protective layers to sophisticated solutions that offer thermal insulation, durability, and aesthetic versatility. This transformation reflects broader trends in construction and materials science, including the push for energy efficiency and the desire for creative architectural expressions. The use of polyurethane in construction dates back to the 1940s, initially utilized for its adhesive qualities and insulation properties. However, it wasn't until the 1960s and 1970s that polyurethane coatings were developed for exterior facades. These early products offered improved weather resistance and maintenance ease compared to traditional materials like wood, metal, and concrete. As technology advanced, so did the composition and capabilities of polyurethane coatings. Innovations in chemical engineering led to products that could withstand extreme temperatures, resist UV radiation, and repel water more effectively. These advancements expanded the applications of polyurethane coatings beyond protection to include energy conservation and aesthetic design. Today, polyurethane facade coatings are at the forefront of modern construction materials, offering a blend of functionality and design flexibility. They are used in a variety of architectural styles, from residential homes to commercial buildings and historical renovations. The coatings are available in a wide range of textures and colors, allowing architects and designers to achieve unique visual effects while enhancing the building's energy efficiency and structural integrity. The production and application of polyurethane coatings have also adapted to the growing environmental concerns. Modern formulations include eco-friendly, low-VOC (volatile organic compound) options, reflecting the industry's shift towards sustainable construction practices. Looking forward, the role of polyurethane facade coatings is expected to expand, driven by innovations in material science and a continued focus on energy efficiency and environmental sustainability. The history of polyurethane facade coatings is a testament to the material's adaptability and enduring appeal in the construction industry. From their humble beginnings to their current status as a staple of modern architectural design, these coatings have continuously evolved to meet the changing needs and challenges of the times. As we look to the future, polyurethane facade coatings are poised to remain an integral part of our built environment, combining aesthetic beauty with practical performance.The Historical Significance of Polyurethane Facade Coating Products

Early Beginnings

Technological Advancements

Modern Applications

Environmental Impact and Future Directions

Conclusion

Polyurethane coatings for both inside and outside walls and facades enhance durability and appearance. These coatings protect exterior panels from weather, improving their longevity and look.

Polyurethane coatings have become a popular choice for protecting and enhancing the appearance of interior and exterior walls, as well as facade panels. Known for their durability, flexibility, and resistance to various environmental factors, these coatings offer a superior solution for both residential and commercial properties. Polyurethane coatings are distinguished by several key properties that make them ideal for wall and facade applications. These include: Polyurethane coatings are versatile and can be applied to a wide range of surfaces, including concrete, wood, metal, and more. They are particularly suited for: With their exceptional durability, weather resistance, flexibility, and aesthetic versatility, polyurethane coatings are an excellent choice for protecting and enhancing the appearance of interior and exterior walls and facade panels. Whether for residential or commercial applications, these coatings provide a long-lasting, attractive finish that can withstand the demands of various environmental conditions.Polyurethane Wall and Facade Coatings

Introduction

Properties of Polyurethane Coatings

Applications

Conclusion

Do polyurethane products for interior and exterior wall facade coatings and exterior panel decorations have different uses?

Polyurethane is a versatile material widely used in the construction industry, particularly for coating and decorating both interior and exterior walls. Its unique properties make it an ideal choice for a range of applications, offering durability, resistance, and aesthetic flexibility. This article explores the separate usage areas of polyurethane for interior and exterior wall facade coating products, including polyurethane exterior panel coating decorations. Inside buildings, polyurethane coatings are primarily used for their aesthetic appeal and protective qualities. They can be applied to a variety of surfaces, including walls, floors, and ceilings, to create a seamless and attractive finish. Polyurethane is known for its ability to resist scratches, stains, and moisture, making it an excellent choice for areas such as kitchens, bathrooms, and high-traffic living spaces. Additionally, its insulating properties can help in reducing energy costs by maintaining consistent indoor temperatures. On the exterior, polyurethane coatings serve a critical role in protecting buildings from the elements. They are designed to withstand harsh weather conditions, including UV radiation, rain, wind, and temperature fluctuations, thereby extending the life of the facade. Polyurethane exterior panel coatings are particularly popular for their durability and ease of maintenance. They can be used on a variety of materials, including wood, metal, and concrete, providing a protective layer that enhances the building's appearance while shielding it from environmental damage. In conclusion, polyurethane coatings offer distinct benefits for both interior and exterior applications. While interior coatings focus on aesthetics and protection against daily wear and tear, exterior coatings are designed to offer robust protection against environmental factors. Regardless of the application, polyurethane provides a durable, versatile, and attractive solution for wall facade coating and decoration needs.Polyurethane Coatings for Interior and Exterior Applications

Interior Applications

Exterior Applications

Conclusion

Polyurethane coatings for interior and exterior walls, and facade coatings - Models of polyurethane coatings for exterior panels.

Polyurethane coatings have become a popular choice for protecting and enhancing the aesthetic appeal of interior and exterior walls. These coatings are renowned for their durability, resistance to weather conditions, and ability to preserve the underlying material. In this article, we will explore the range of polyurethane facade and panel coating models available for both interior and exterior applications. Polyurethane coatings offer several benefits, making them an ideal choice for both residential and commercial buildings. Some of these benefits include: The choice of polyurethane exterior panel coating models is vast, catering to different architectural styles and preferences. Some popular models include: Applying polyurethane coatings requires precision and expertise. The process typically involves surface preparation, including cleaning and priming, followed by the application of the polyurethane coating. It is crucial to ensure the surface is dry and free of any contaminants to achieve optimal adhesion and finish. Professional application is recommended to ensure durability and the desired aesthetic outcome. Polyurethane coatings offer an effective and versatile solution for protecting and enhancing the appearance of interior and exterior walls. With a range of models and finishes available, they provide the durability, weather resistance, and aesthetic flexibility needed to meet the demands of modern architectural design. Whether for residential or commercial buildings, polyurethane coatings are a wise investment in maintaining and beautifying structures for years to come.Polyurethane Coating Products for Interior and Exterior Walls

Benefits of Polyurethane Coatings

Polyurethane Exterior Panel Coating Models

Application of Polyurethane Coatings

Conclusion

Yes, polyurethane coatings can be used on exterior walls.

Polyurethane coatings are widely recognized for their durability, resilience, and aesthetic versatility, making them a popular choice for both interior and exterior applications. When it comes to exterior walls, polyurethane facade coatings offer several benefits that make them an excellent option for protecting and enhancing the building's appearance. Polyurethane coatings for exterior walls are designed to withstand harsh weather conditions, UV radiation, and other environmental factors that can cause wear and tear over time. These coatings provide a protective layer that not only enhances the wall's resistance to moisture, mold, and mildew but also contributes to energy efficiency by creating a more insulated building envelope. Furthermore, polyurethane exterior panel coatings are available in a variety of colors and finishes, allowing for complete customization to match any architectural style or design preference. Their flexibility and ability to adhere to different substrates make them suitable for a wide range of exterior surfaces, including wood, metal, and concrete. While polyurethane coatings offer many advantages, proper application is crucial to achieving the desired performance and aesthetics. Preparation of the surface is key; it must be clean, dry, and free of any contaminants or loose material. Applying the coating under the right weather conditions is also important to ensure proper curing and adhesion. It's recommended to work with professional applicators who have experience with polyurethane products to ensure the best outcome. They can provide valuable guidance on the specific product selection, application techniques, and maintenance requirements to extend the life of the coating. Polyurethane interior and exterior wall facade coatings are a robust solution for enhancing the durability and appearance of exterior walls. Their protective qualities and aesthetic flexibility make them a compelling choice for a wide range of projects. With proper application and maintenance, polyurethane exterior panel coatings can provide long-lasting beauty and protection for any building.Using Polyurethane Coatings on Exterior Walls

Benefits of Polyurethane Exterior Wall Coatings

Application Considerations

Conclusion

Can polyurethane coatings for both interior and exterior walls, including facade and panel coatings, be painted?

When it comes to revamping the exterior or interior walls of our homes or buildings, we often come across surfaces coated with polyurethane. This durable material is widely used for its protective qualities, providing a barrier against weather and wear. However, the question arises: Can polyurethane interior and exterior wall facade coating products be painted over? Polyurethane coatings are applied to surfaces to protect them from environmental damage and to enhance their aesthetic appeal. These coatings are known for their durability, resistance to chemicals, and flexibility. They can be used on a variety of surfaces including wood, metal, and concrete, making them a popular choice for both interior and exterior applications. Before painting over a polyurethane-coated surface, proper preparation is crucial to ensure the new paint adheres well and lasts. This typically involves cleaning the surface thoroughly to remove any dirt, grease, or other contaminants. After cleaning, the surface should be lightly sanded to create a rough texture for the new paint to grip onto. It's important to wipe away any dust from sanding before proceeding. Not all paints are suitable for use over polyurethane coatings. Water-based acrylic paints are generally recommended due to their ability to adhere well to polyurethane surfaces. However, it's essential to use a high-quality primer designed for use on non-porous surfaces to ensure the best results. The primer will provide a good base for the paint, improving its durability and appearance. When applying paint over polyurethane, it's important to use thin coats and allow adequate drying time between layers. This will help prevent the paint from peeling or bubbling. Additionally, using a brush, roller, or sprayer that is suitable for the type of paint being used will ensure a smooth, even finish. In summary, polyurethane interior and exterior wall facade coating products can indeed be painted, provided the surface is properly prepared, the right type of paint and primer is used, and the paint is applied correctly. With careful preparation and application, you can successfully refresh or transform the appearance of polyurethane-coated surfaces.Painting Polyurethane Coated Surfaces

Understanding Polyurethane Coatings

Preparing to Paint Over Polyurethane

Choosing the Right Paint

Application Tips

Conclusion

To apply polyurethane coating on interior and exterior walls, follow these steps: 1. Prepare the surface by cleaning and smoothing it. Remove any dirt, grease, or peeling paint. For new surfaces, sanding may be necessary for better adhesion. 2. Apply a primer if recommended by the polyurethane manufacturer. This helps the polyurethane coat adhere better and last longer. 3. Once the primer is dry, mix the polyurethane product according to the instructions. Some products may require thinning. 4. Use a brush, roller, or sprayer to apply the polyurethane. Start from the top and work your way down to prevent drips. 5. Apply the polyurethane in thin, even coats. It's better to apply multiple thin coats than one thick coat. Allow each coat to dry completely before applying the next. 6. After the final coat, allow the surface to cure for the time specified by the product. Avoid touching or using the surface during this time. For exterior panels, the process is similar. Ensure the panels are clean, dry, and primed if necessary. Apply the polyurethane in thin, even coats, allowing each coat to dry before applying the next.

Polyurethane coatings are widely recognized for their durability, resilience, and aesthetic versatility, making them an ideal choice for both interior and exterior wall applications. This guide will walk you through the steps to correctly apply polyurethane facade and panel coatings, ensuring your surfaces are not only protected but also visually appealing. Before applying polyurethane coatings, it's crucial to prepare the surface properly. Ensure the wall is clean, dry, and free of any dust, grease, or previous paint residues. For exterior applications, consider pressure washing the surface to remove any exterior dirt or grime. For the application of polyurethane coatings, you can use a brush, roller, or a spray gun. Brushes are ideal for small areas or detailed work, rollers can cover larger surfaces more efficiently, and spray guns are perfect for achieving an even coat over expansive or textured surfaces. Start by applying a primer if necessary, especially for surfaces that have not been previously treated or are prone to moisture. Once the primer is dry, stir your polyurethane coating thoroughly. Apply the first coat thinly and evenly. Allow it to dry completely, following the manufacturer's recommended drying time, before applying a second coat. For exterior surfaces exposed to harsh weather, consider a third coat for extra protection. Allow the final coat of polyurethane to dry and cure fully. Drying times can vary based on temperature, humidity, and ventilation. Avoid touching or cleaning the coated surfaces during this period to ensure a flawless finish. Polyurethane-coated surfaces are relatively low maintenance. Regular cleaning with mild soap and water will help maintain their appearance and longevity. Avoid using abrasive cleaners or pads that can scratch or damage the coating. Applying polyurethane coatings to interior and exterior walls not only enhances their durability and aesthetic appeal but also provides a protective layer against environmental elements. With the right preparation, tools, and application techniques, you can achieve professional-grade results that last for years.Applying Polyurethane Coatings on Interior and Exterior Walls

Introduction

Preparation

Application Tools

Application Process

Drying and Curing

Maintenance

Conclusion

The difference lies in the base material used. Polyurethane coatings are based on polyurethane, a type of plastic, which provides durability and resistance to weather conditions for both interior and exterior surfaces. Styrofoam coatings, on the other hand, use Styrofoam (expanded polystyrene) as the base, which is then coated with polyurethane for protection. Styrofoam-based coatings are lighter and may offer better insulation but might not be as durable as pure polyurethane coatings.

When it comes to protecting and enhancing the aesthetic appeal of interior and exterior walls, choosing the right facade coating product is crucial. Among the popular options are polyurethane and styrofoam coatings. Both materials offer unique benefits and limitations, making them suitable for different applications. This article explores the key differences between polyurethane and styrofoam interior & exterior wall facade coating products. Polyurethane coatings are known for their exceptional durability, resistance to weather, chemicals, and UV radiation, making them an ideal choice for exterior panel coatings. These coatings form a hard, yet flexible layer that can withstand significant environmental stress without cracking or peeling. Polyurethane is also appreciated for its aesthetic versatility, available in various finishes and colors to match architectural designs. Its application on interior walls enhances durability and ease of maintenance, providing a long-lasting finish. Styrofoam coatings, on the other hand, are primarily used for their insulation properties. When applied to interior and exterior walls, they contribute to thermal insulation, helping in energy conservation by keeping indoor temperatures stable. Styrofoam coatings are lightweight, making them easy to handle and apply. However, they are less durable than polyurethane and are susceptible to physical damage. They are typically used in conjunction with other protective layers to enhance their durability and resistance to environmental factors. Choosing between polyurethane and styrofoam coatings for interior and exterior walls depends on the specific requirements of the project. Polyurethane is ideal for those prioritizing durability, aesthetic flexibility, and resistance to environmental factors. Styrofoam is suitable for projects where insulation is a critical concern. Understanding the properties and applications of each material will help in making an informed decision to achieve the desired outcome for your facade coating needs.Difference Between Polyurethane and Styrofoam Coatings for Interior & Exterior Walls

Polyurethane Coatings

Styrofoam Coatings

Key Differences

Conclusion

The difference lies in their application areas: interior coatings are designed for indoor use, while exterior coatings are formulated to withstand outdoor conditions on walls and panels.

Polyurethane coatings have become a popular choice for protecting and enhancing the aesthetic appeal of both interior and exterior walls. Despite their similar chemical makeup, polyurethane interior and exterior facade coatings are formulated differently to meet the unique demands of their respective environments. Understanding these differences is crucial for selecting the right product for your project. Exterior polyurethane facade coatings are specifically designed to withstand harsh weather conditions, including UV radiation, rain, wind, and temperature fluctuations. These products contain additives that enhance their durability and resistance to fading, cracking, and peeling. In contrast, interior polyurethane coatings are not exposed to the same level of environmental stress and thus do not require the same level of protective additives. While both types of coatings are available in various finishes, exterior polyurethane coatings often have a wider range of UV-resistant colors to maintain their appearance over time. Interior coatings, on the other hand, focus more on the aesthetic and tactile qualities, offering finishes that complement interior decor and provide a desirable feel to the touch. The chemical composition of exterior polyurethane coatings is adjusted to provide enhanced resistance to environmental factors. These coatings may contain higher levels of polyols and isocyanates, which contribute to their durability and longevity. Interior polyurethane coatings might have a different balance of these chemicals to prioritize ease of application, drying time, and indoor air quality. Due to the need for indoor air quality control, interior polyurethane coatings are formulated to have lower volatile organic compound (VOC) levels. Exterior coatings, while also regulated, can have higher VOC levels as they are applied in open environments where ventilation is less of a concern. When choosing between interior and exterior polyurethane facade coatings, it is essential to consider the specific requirements of your project. Exterior coatings are tailored to protect against the elements and maintain their appearance in harsh conditions, while interior coatings are designed with aesthetics and indoor environmental quality in mind. By understanding these differences, you can ensure the longevity and beauty of your walls, whether they are inside or out.Differences Between Interior & Exterior Polyurethane Facade Coatings

Exposure to Elements

Appearance and Aesthetics

Chemical Composition

VOC Content

Conclusion

Polyurethane precast is made from a type of plastic that's strong and can be molded into shapes easily. It's lightweight and has good insulation properties. GRC precast, which stands for Glassfibre Reinforced Concrete, is a mixture of cement, fine aggregate, water, chemical admixtures, and glass fibers. It's known for being very strong, durable, and able to be made into thin, lightweight panels.

When it comes to building materials, particularly for external facades, landscaping, and decorative features, two prominent materials often considered are Polyurethane (PU) Precast and Glassfibre Reinforced Concrete (GRC) Precast. Both materials offer unique advantages and have distinct characteristics that make them suitable for different applications. Understanding the difference between these two can help architects, builders, and developers make informed decisions. Polyurethane Precast is a type of building material made by casting polyurethane, a type of polymer, into molds to create various shapes and designs. This material is known for its lightweight, flexibility, and durability. Polyurethane precast is often used for decorative elements, such as moldings, trims, and facade panels, due to its ability to replicate fine details and textures. Glassfibre Reinforced Concrete (GRC) Precast is a composite material consisting of cement, fine aggregates, water, chemical admixtures, and alkali-resistant glass fibers. This composition gives GRC its strength, durability, and versatility. GRC precast is widely used for exterior facade panels, architectural cladding, and landscaping elements because of its robustness and ability to withstand harsh environmental conditions. In conclusion, both Polyurethane Precast and GRC Precast have their places in construction, each offering unique benefits. The choice between them depends on the specific requirements of the project, including considerations of weight, durability, design flexibility, and environmental impact. By understanding these differences, decision-makers can select the most appropriate material for their needs.Difference Between Polyurethane Precast and GRC Precast

What is Polyurethane Precast?

What is GRC Precast?

Key Differences

Conclusion

Polyurethane products for coating interior and exterior walls and facades - Prices for polyurethane coatings for exterior panels.

Polyurethane coatings are widely recognized for their exceptional durability, resistance to environmental elements, and versatility. These coatings are particularly beneficial for both interior and exterior wall applications, offering an excellent balance of aesthetic appeal and long-lasting protection. This article delves into the world of polyurethane facade coatings, focusing on their benefits, applications, and the price range for polyurethane exterior panel coatings. Polyurethane wall coatings offer numerous advantages, making them a preferred choice for both residential and commercial properties. These benefits include: Polyurethane facade coatings are suitable for a variety of surfaces, including concrete, masonry, wood, and metal. They are commonly used in: The cost of polyurethane exterior panel coatings can vary widely based on factors such as the quality of the product, the size of the area to be covered, and the specific requirements of the project. On average, prices can range from: It's important to consult with a professional to get an accurate estimate for your specific project, as well as to ensure the correct application techniques are used for optimal results.Polyurethane Coating Products for Interior and Exterior Walls

Benefits of Polyurethane Wall Coatings

Applications of Polyurethane Facade Coatings

Polyurethane Exterior Panel Coating Prices

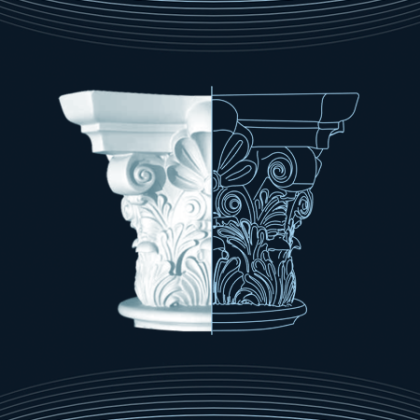

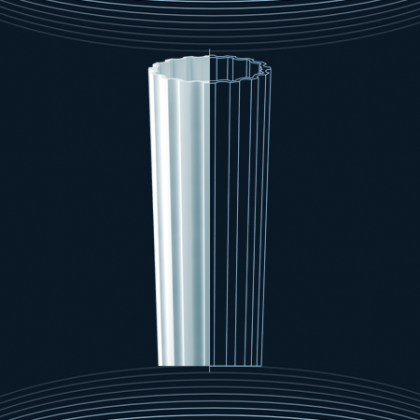

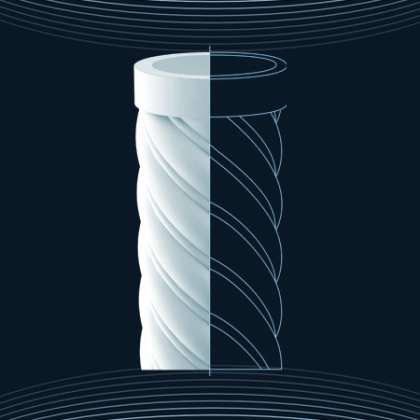

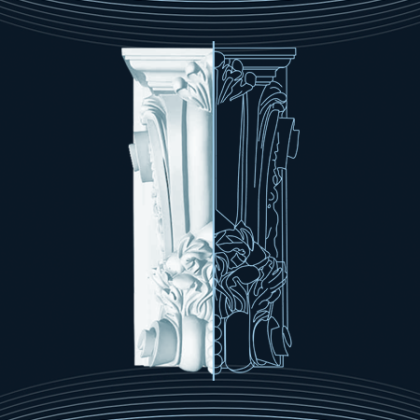

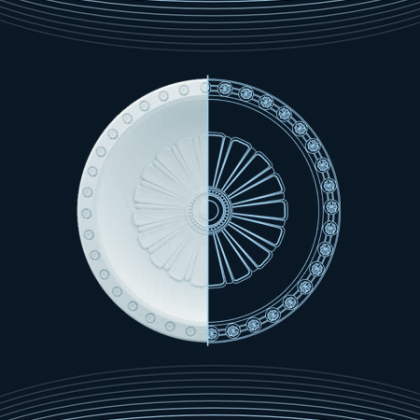

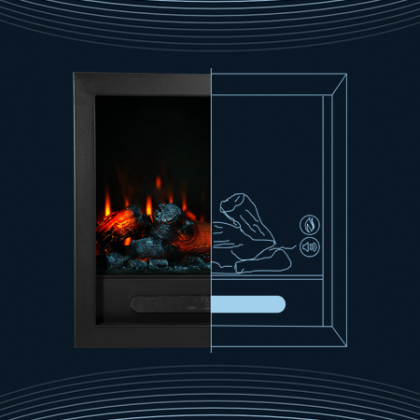

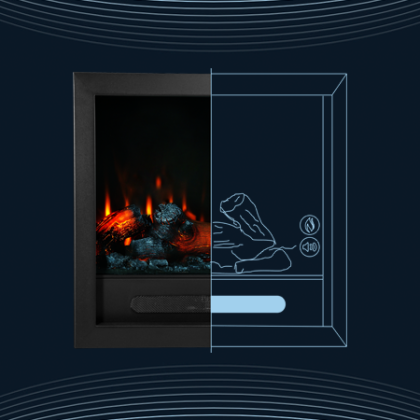

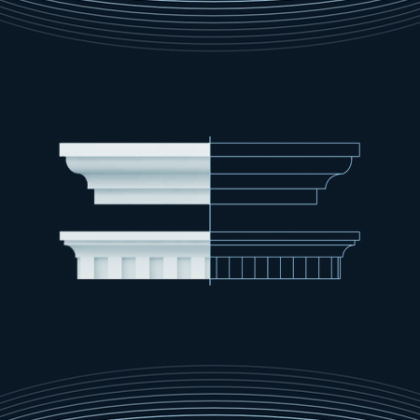

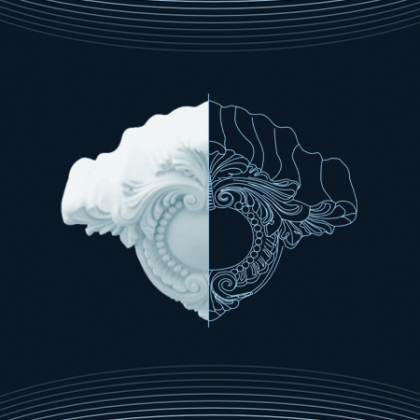

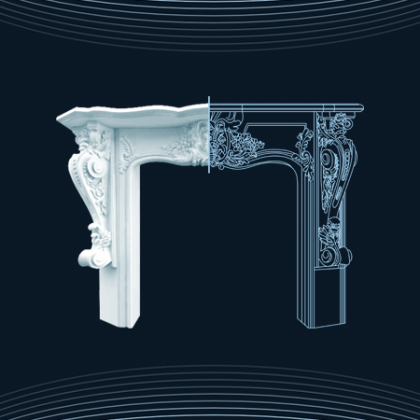

Information Gallery

List of detailed descriptions of images in the image gallery.

English

English

Romanian

Romanian